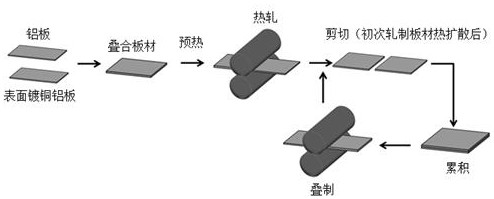

A method for stacking multilayer aluminum/copper composite boards with copper atoms deposited on the surface

A surface deposition and composite board technology, applied in chemical instruments and methods, manufacturing tools, layered products, etc., can solve the problems of uneven distribution of composite board interfaces, unsatisfactory mechanical properties, low interface bonding strength, etc., and achieve interface bonding Good, enhanced mechanical properties, improved interfacial bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

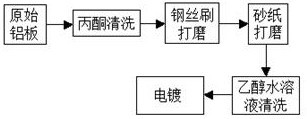

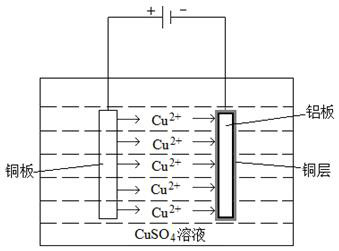

[0027] Take the original aluminum plate with a thickness of 1mm, wash it with acetone, remove the oxide film on the surface of the original aluminum plate with a stainless steel brush with a steel wire diameter of 0.2mm, and then use 800# sandpaper, 1000# sandpaper, and 2000# sandpaper to polish the surface of the original aluminum plate. Then clean it with ethanol aqueous solution in an ultrasonic cleaning machine, dry it, put the original aluminum plate after surface treatment into the electroplating solution, at room temperature, under the electric current 2A / dm 2 , Under the condition of voltage 1V, electroplating for 1h, such as figure 2 Shown; each liter of plating solution contains 20mL of H 2 SO 4 and 240g of CuSO 4 ·5H 2 O; Copper atoms are evenly deposited on the surface of the treated original aluminum plate by electroplating, see image 3 , to get a copper-plated aluminum plate; along the thickness of the 2mm aluminum plate to be rolled, use a stainless steel ...

Embodiment 2

[0031]Take the original aluminum plate with a thickness of 2mm, wash it with acetone, remove the oxide film on the surface of the original aluminum plate with a stainless steel brush with a steel wire diameter of 0.1mm, and then use 800# sandpaper, 1000# sandpaper, and 2000# sandpaper to polish the surface of the original aluminum plate. Then clean it with ethanol aqueous solution in an ultrasonic cleaning machine, dry it, put the original aluminum plate after surface treatment into the electroplating solution, at room temperature, under the electric current 2A / dm 2 , Under the condition of voltage 5V, electroplating for 8 minutes; each liter of electroplating solution contains 20mL of H 2 SO 4 and 240g of CuSO 4 ·5H 2 O; Copper atoms are uniformly deposited on the surface of the treated original aluminum plate by electroplating to obtain a copper-plated aluminum plate; the aluminum plate with a thickness of 1.5 mm is to be rolled along the direction to be rolled with a stai...

Embodiment 3

[0033] Take the original aluminum plate with a thickness of 1.5mm, wash it with acetone, and then use a stainless steel brush with a diameter of 0.15mm to remove the oxide film on the surface of the original aluminum plate, and then use 800# sandpaper, 1000# sandpaper, and 2000# sandpaper to polish the surface of the original aluminum plate , and then cleaned with ethanol aqueous solution in an ultrasonic cleaning machine, dried, and put the original aluminum plate after surface treatment into the electroplating solution, at room temperature, at a current of 2A / dm 2 , Under the condition of voltage 3V, electroplating for 30min; each liter of electroplating solution contains 20mL of H 2 SO 4 and 240g of CuSO 4 ·5H 2 0; Copper atoms are evenly deposited on the surface of the treated original aluminum plate by electroplating to obtain a copper-plated aluminum plate; along the aluminum plate with a thickness of 1 mm, the stainless steel brush with a steel wire diameter of 0.15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap