A method for recycling waste polyurethane foam and its application

A polyurethane foam and carbon material technology, applied in the field of polyurethane foam, can solve problems such as difficult industrialization and complicated processes, and achieve good cycle stability, high specific capacity, and simple and direct methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

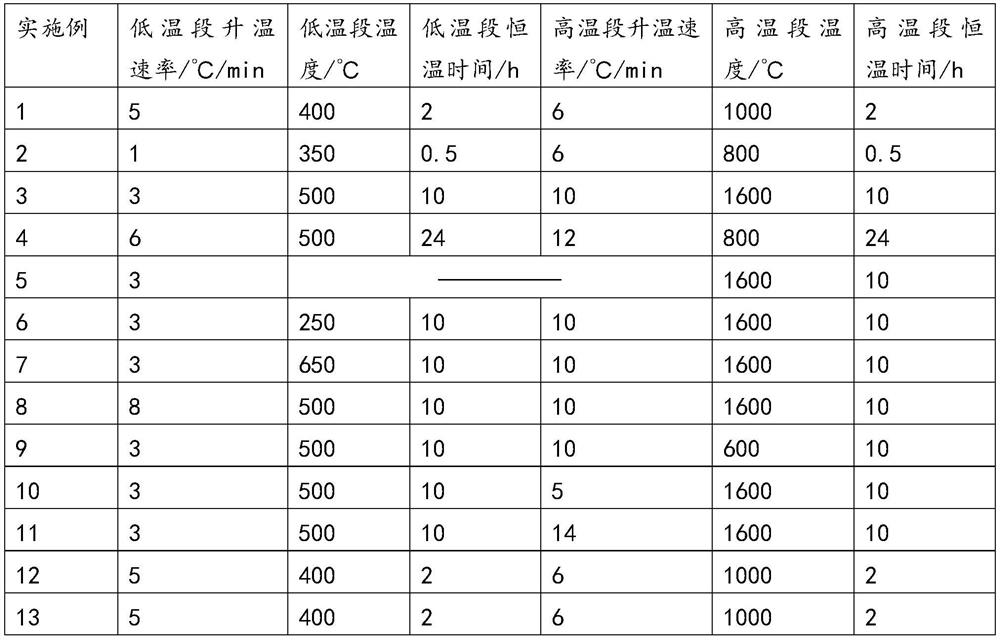

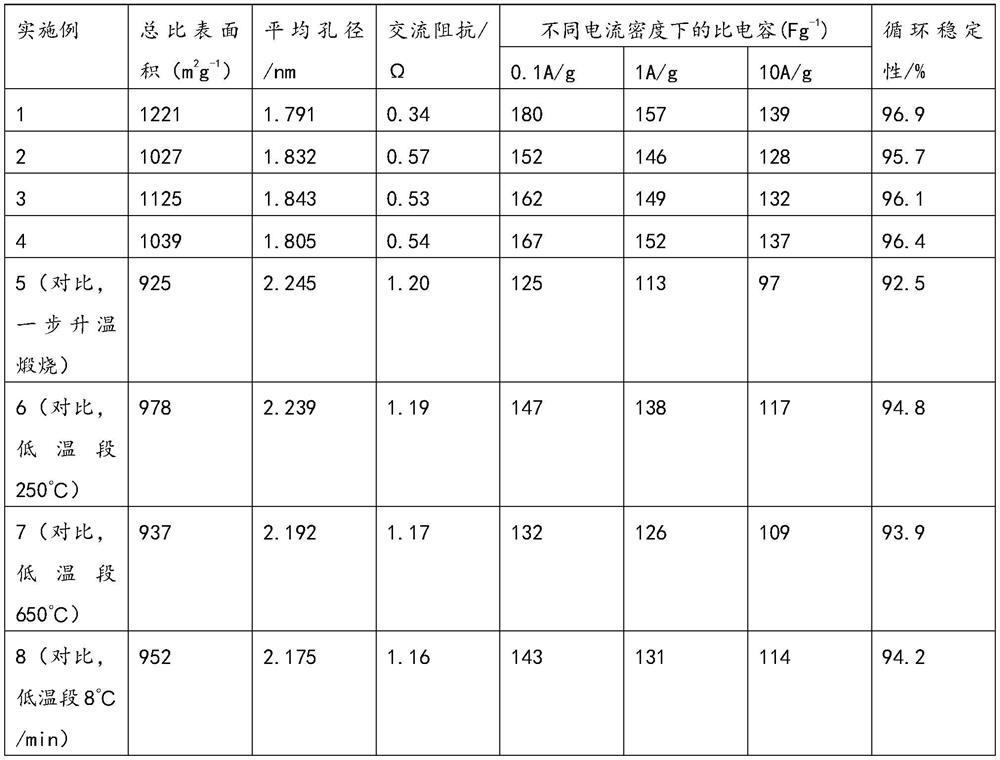

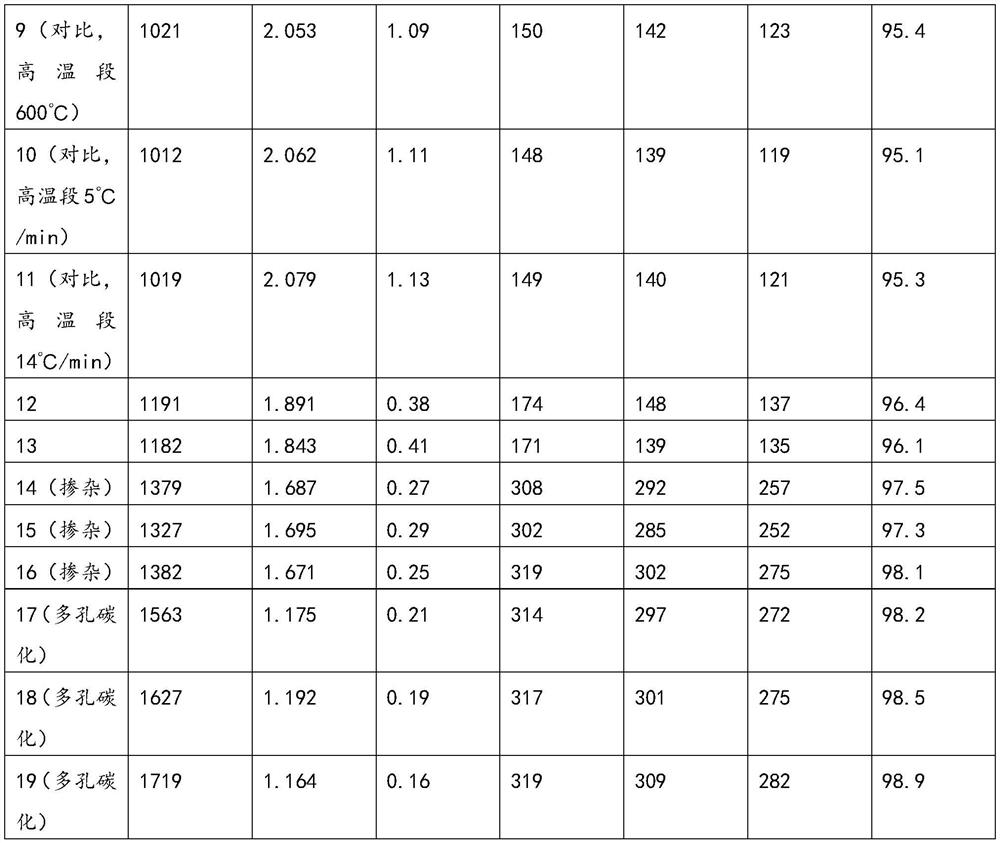

Embodiment 1

[0058] Using waste polyurethane rigid foam as raw material, it was soaked in ethanol and ultrasonically cleaned to remove mechanical impurities without other pretreatment. It is first cut into a fixed shape suitable for the size of the tube furnace, and its mass is said to be 200 mg. Put the waste polyurethane foam in a porcelain boat, place the porcelain boat in a tube furnace, and heat it at 5°C min under a nitrogen protective atmosphere. -1 The heating rate (i.e. the heating rate of the low-temperature section) was raised to 400°C (i.e. the temperature of the low-temperature section) and calcined for 2 hours (i.e. the constant temperature time of the low-temperature section), and the temperature was naturally cooled to room temperature to obtain a pre-carbonized carbon material;

[0059] Then, under the protection of nitrogen, continue at 6°C·min -1 The heating rate (that is, the heating rate of the high temperature section) is raised to 1000°C (ie, the temperature of the ...

Embodiment 2-4

[0062] The raw material of embodiment 2-4 is consistent with embodiment 1. The difference lies in the heating rate of the low temperature section, the temperature of the low temperature section, the constant temperature time of the low temperature section, the heating rate of the high temperature section, the temperature of the high temperature section and the constant temperature time of the high temperature section, see Table 1 for details.

Embodiment 5-11

[0063] Embodiment 5-11 (comparison)

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com