Wastewater treatment ozone catalytic oxidation reactor

A technology for ozone catalytic oxidation and wastewater treatment, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc. Low utilization rate and other problems, to achieve good catalytic oxidation effect, improve COD removal rate, improve the effect of ozone reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

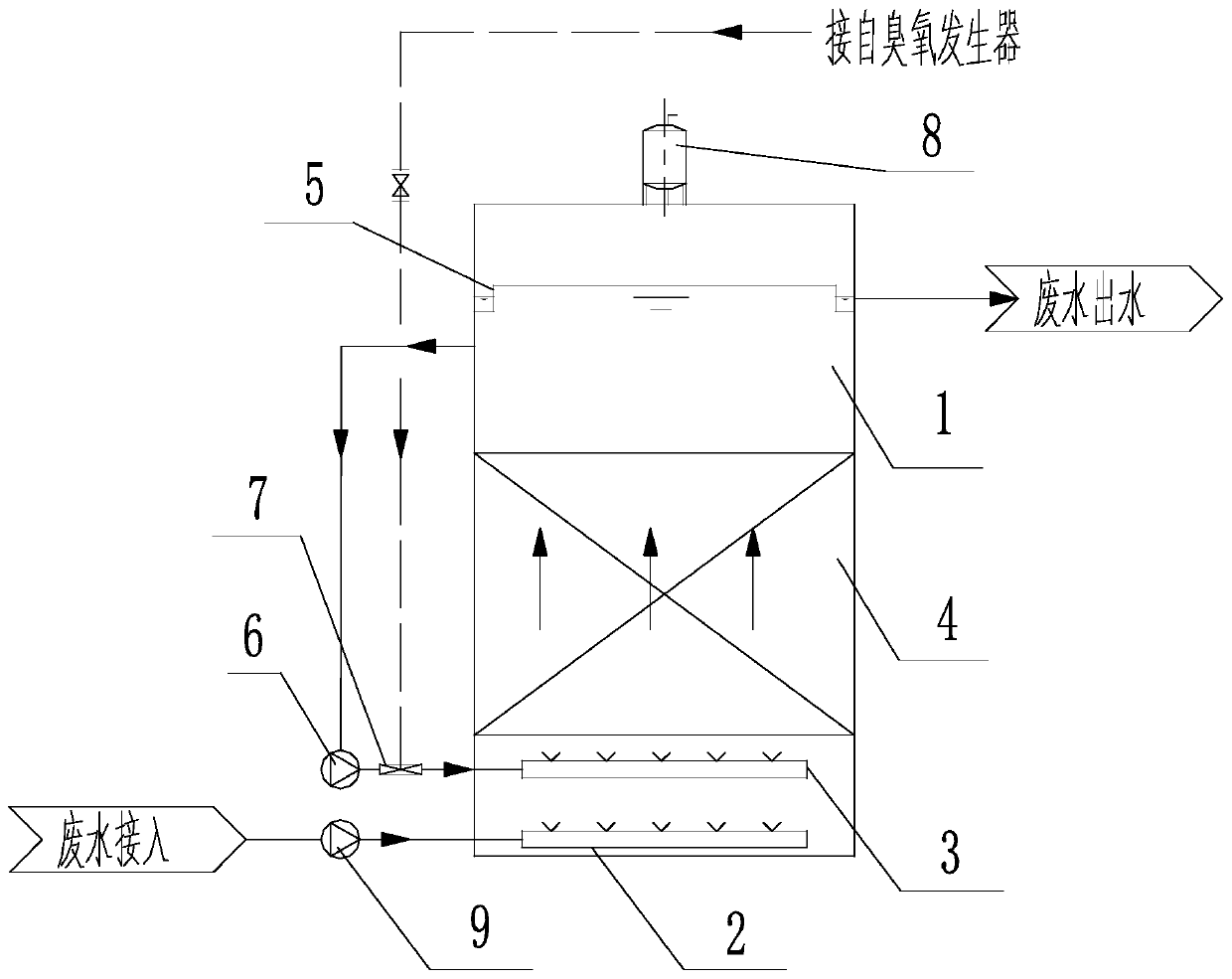

[0018] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0019] Such as figure 1 As shown, a wastewater treatment ozone catalytic oxidation reactor includes an ozone catalytic oxidation reaction chamber 1, an ozone catalyst packing layer 4 is arranged in the ozone catalytic oxidation reaction chamber 1, and a water inlet cloth is arranged below the ozone catalyst packing layer 4 The water device 2 and the gas-water mixed liquid water distributor 3, the water outlet weir plate 5 is arranged above the ozone catalyst packing layer 4, and the treated waste water is collected by the water outlet weir plate 5 and discharged.

[0020] The inlet of the gas-water mixed liquid water distributor 3 is connected to the outlet of the return pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com