Improved high strength scratch-resistant polypropylene material and preparation method thereof

A polypropylene material, scratch-resistant technology, applied in the field of polypropylene materials, can solve the problems of short fiber retention length, low production efficiency, poor performance of metallocene polyethylene, etc., to enhance interface bonding force, improve production efficiency, improve The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

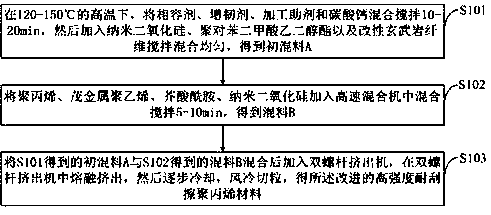

[0038] Such as figure 1 As shown, the preparation method of the improved high-strength scratch-resistant polypropylene material provided by the embodiment of the present invention includes the following steps:

[0039] S101: At a high temperature of 120-150°C, mix and stir the compatibilizer, toughening agent, processing aid and calcium carbonate for 10-20 minutes, then add nano-silica, polyethylene terephthalate and modified Stir and mix the basalt fiber evenly to obtain primary mixture A.

[0040] S102: Add polypropylene, metallocene polyethylene, erucamide, and nano-silicon dioxide into a high-speed mixer and mix for 5-10 minutes to obtain a mixture B.

[0041] S103: Mix the primary compound A obtained in S101 with the compound B obtained in S102, add it to a twin-screw extruder, melt and extrude it in the twin-screw extruder, then gradually cool, air-cool and pelletize to obtain the improved High-strength scratch-resistant polypropylene material.

[0042] In S101 provid...

Embodiment 1

[0057] The improved high-strength scratch-resistant polypropylene material provided by Example 1 of the present invention consists of 40% polypropylene, 12% polyethylene terephthalate, 10% metallocene polyethylene, 8 % calcium carbonate, 5% erucamide, 13% modified basalt fiber, 5% toughening agent, 3%-6% compatibilizer, 3.5% nano-silica and 0.5% processing aid agent composition.

[0058] The preparation method of the improved high-strength scratch-resistant polypropylene material provided in Example 1 of the present invention comprises the following steps:

[0059] (1) Mix compatibilizer, toughening agent, processing aid and calcium carbonate at a high temperature of 120°C for 10 minutes, then add nano-silica, polyethylene terephthalate and modified basalt fiber Stir and mix evenly to obtain primary mix A.

[0060] (2) Add polypropylene, metallocene polyethylene, erucamide, and nano-silicon dioxide into a high-speed mixer and mix for 5 minutes to obtain mixture B.

[0061] ...

Embodiment 2

[0063] The improved high-strength scratch-resistant polypropylene material provided by Example 2 of the present invention consists of 41% polypropylene, 13% polyethylene terephthalate, 10% metallocene polyethylene, 9 % calcium carbonate, 5% erucamide, 10% modified basalt fiber, 5% toughening agent, 3.8% compatibilizer, 3% nano-silica and 0.2% processing aid.

[0064] The preparation method of the improved high-strength scratch-resistant polypropylene material provided by Example 2 of the present invention comprises the following steps:

[0065] (1) Mix compatibilizer, toughening agent, processing aid and calcium carbonate at a high temperature of 130°C for 15 minutes, then add nano-silica, polyethylene terephthalate and modified basalt fiber Stir and mix evenly to obtain primary mix A.

[0066] (2) Add polypropylene, metallocene polyethylene, erucamide, and nano-silicon dioxide into a high-speed mixer and mix for 8 minutes to obtain mixture B.

[0067] (3) Mix the primary co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com