Polyethylene glycol/hydroxypropyl cellulose carbon nanotube composite solid-solid phase change material and preparation method thereof

A composite technology of hydroxypropyl cellulose and carbon nanotubes, used in heat exchange materials, chemical instruments and methods, etc., can solve problems such as liquid leakage and low thermal conductivity, and achieve improved thermal conductivity, green and clean environment, and synthetic routes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

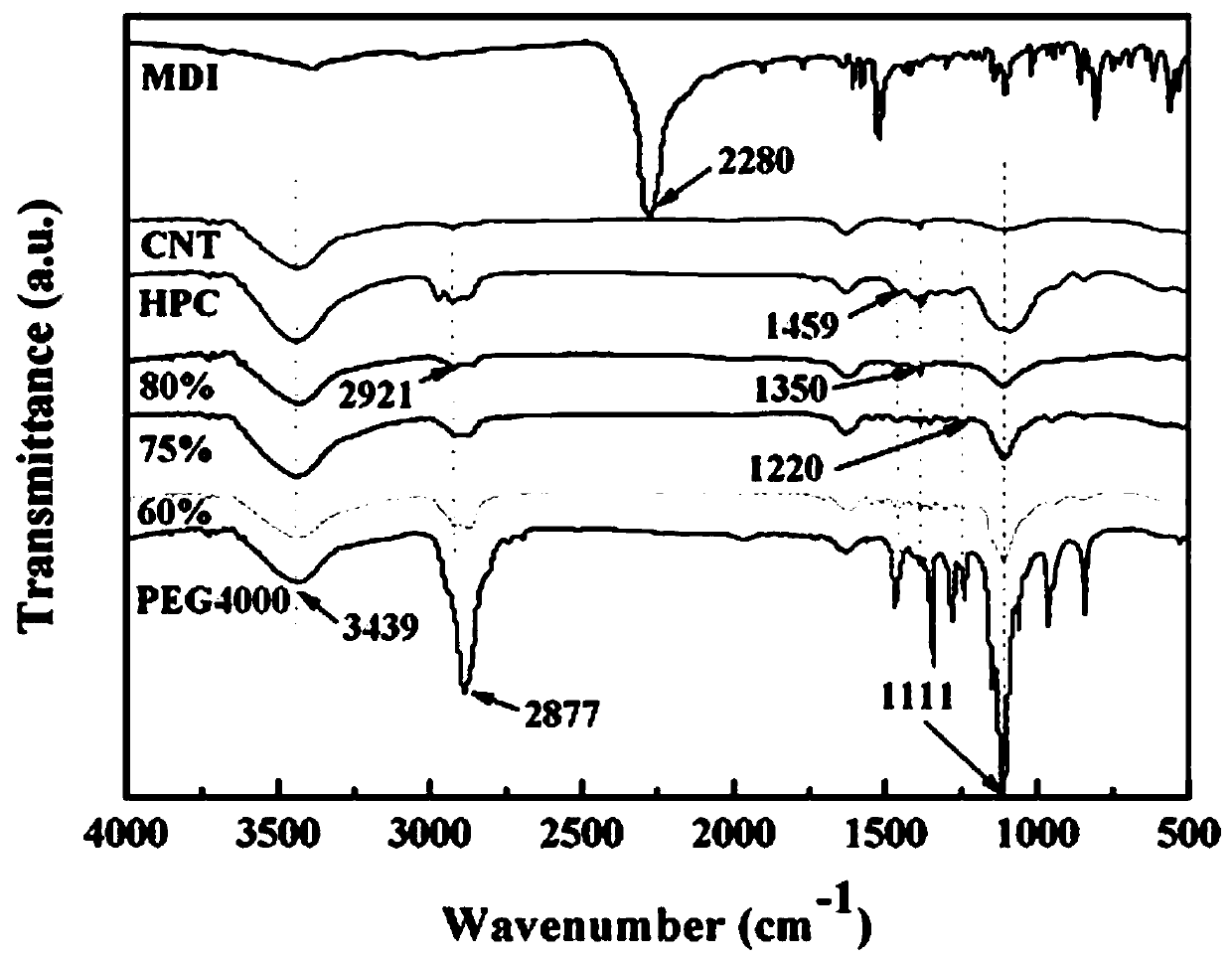

[0042] A preparation method of polyethylene glycol / hydroxypropyl cellulose carbon nanotube composite solid-solid phase change material comprises the following steps:

[0043] Step 1) Preparation of NCO-PEG prepolymer, add 8gPEG4000 and 1gMDI into MDF respectively to dissolve and configure a solution, and slowly add the PEG4000 solution into the MDI solution under the condition of passing inert gas, and keep the temperature at 85°C Stir the reaction in an oil bath, condense and reflux for 3 hours to obtain an NCO-PEG prepolymer.

[0044] Step 2) Preparation of cross-linked polymer, add 1.5560g hydroxypropyl cellulose to DMF and stir to dissolve, then add to NCO-PEG prepolymer, 85 ℃ constant temperature oil bath, stir reaction, condense and reflux for 7 hours, that is Obtain cross-linked polymer;

[0045] Step 3) Preparation of composite phase change materials, adding 0.1067g carbon nanotubes into DMF to disperse uniformly by ultrasonic, then adding to the prepared cross-linked...

Embodiment 2

[0057] A preparation method of polyethylene glycol / hydroxypropyl cellulose carbon nanotube composite solid-solid phase change material (the content of polyethylene glycol is 60%, and the sample is named SSPCM-60%), steps not specified Same as Example 1, except that in the step 2, the content of hydroxypropyl cellulose is 4.2 g, and the mass of the carbon nanotubes added in the step 3 is 0.133 g.

[0058] In order to prove that the prepared SSPCM-60% phase change thermal performance is good, a differential scanning calorimetry (DSC) test was carried out, the test method was the same as in Example 1, and the phase change temperature and phase change enthalpy of SSPCM-60% were obtained Such as Figure 4 As shown, the phase transition temperature is 33.7-51.5 ℃, the phase transition enthalpy value is 99.7-101.2 J / g, and the phase transition enthalpy value is lower than that of SSPCM-75%.

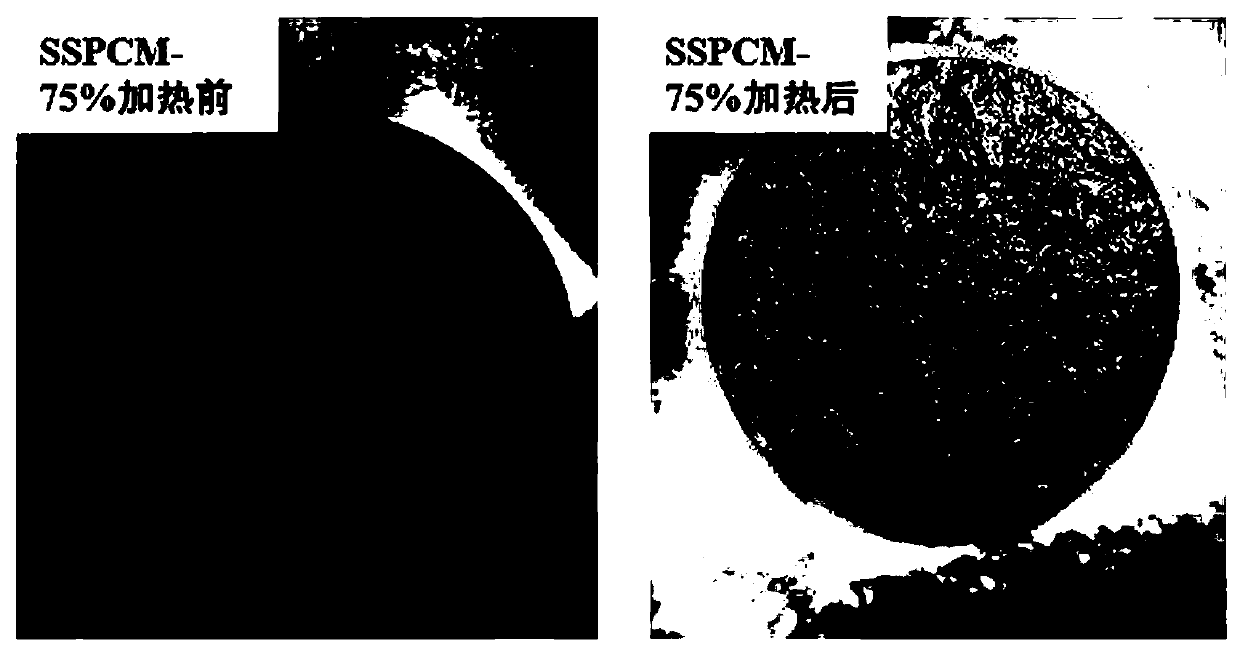

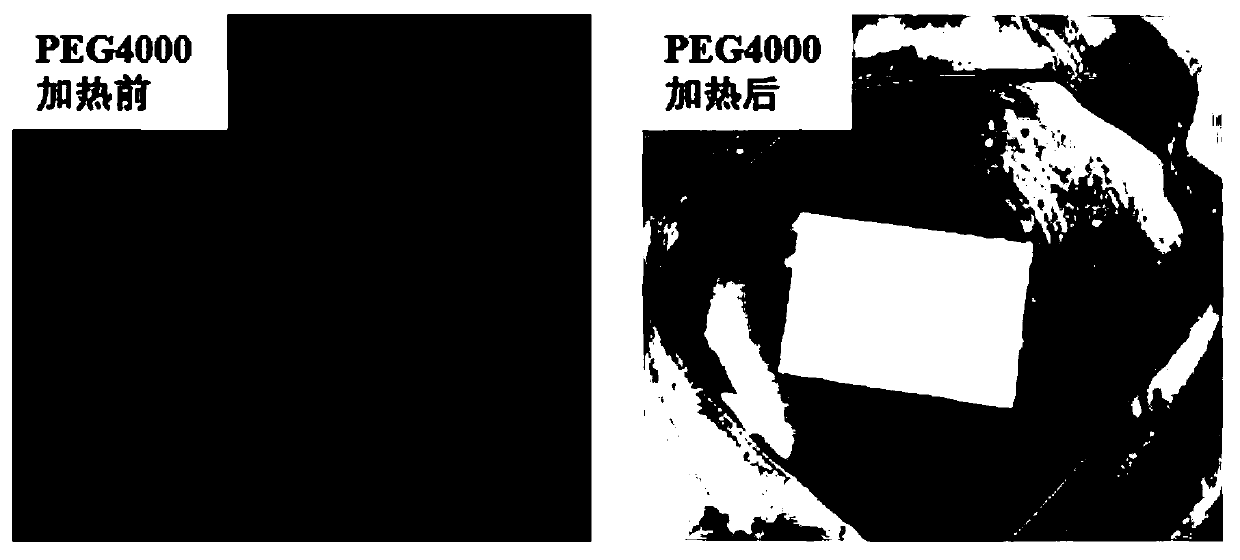

[0059] In order to prove the anti-leakage effect of the present invention, a heating contra...

Embodiment 3

[0061] A preparation method of polyethylene glycol / hydroxypropyl cellulose carbon nanotube composite solid-solid phase change material (the content of polyethylene glycol is 80%, and the sample is named SSPCM-80%), steps not specified Same as Example 1, except that: in the step 2, the content of hydroxypropyl cellulose is 0.9 g, and the mass of the carbon nanotubes added in the step 3 is 0.1 g.

[0062] In order to prove that the prepared SSPCM-80% phase change thermal performance is good, a differential scanning calorimetry (DSC) test was carried out, the test method was the same as in Example 1, and the phase change temperature and phase change enthalpy of SSPCM-80% were obtained Such as Figure 4 As shown, the phase change temperature of the phase change material is 35.6-51.7 ℃, the phase change enthalpy value is 131.1-134.6 J / g, and the phase change enthalpy value is increased relative to the enthalpy value of SSPCM-75%.

[0063] In order to prove the anti-leakage effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com