Dynamic temperature control method for converter CO2-O2 mixed injecting and smelting fire point region

A CO2-O2, dynamic control technology, applied in the field of iron and steel metallurgy, can solve problems such as difficulty in effective utilization, and achieve the effects of efficient utilization, improving metal yield, and suppressing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The invention provides a converter CO 2 -O 2 A method for dynamic control of temperature in the ignition zone of mixed injection smelting.

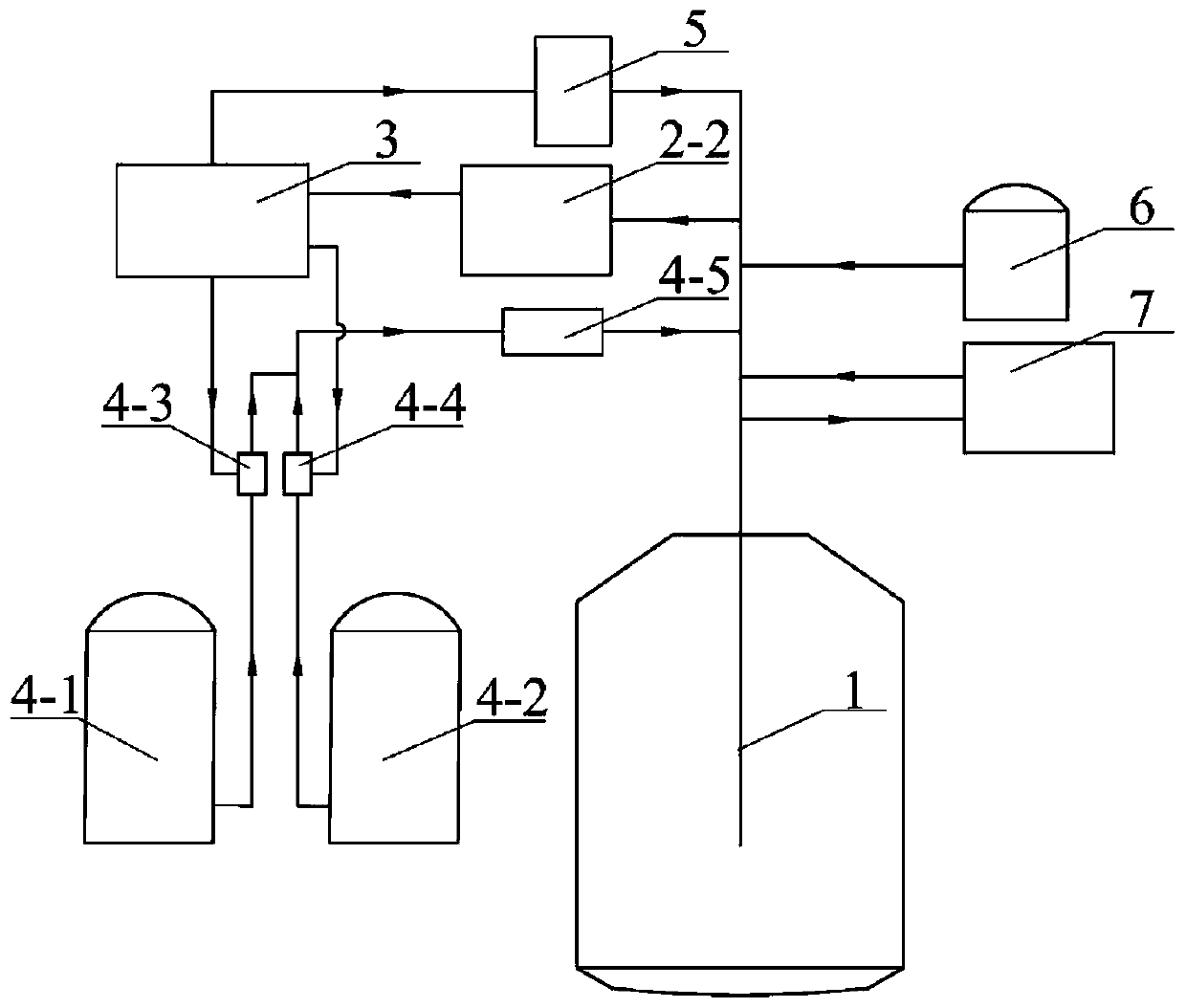

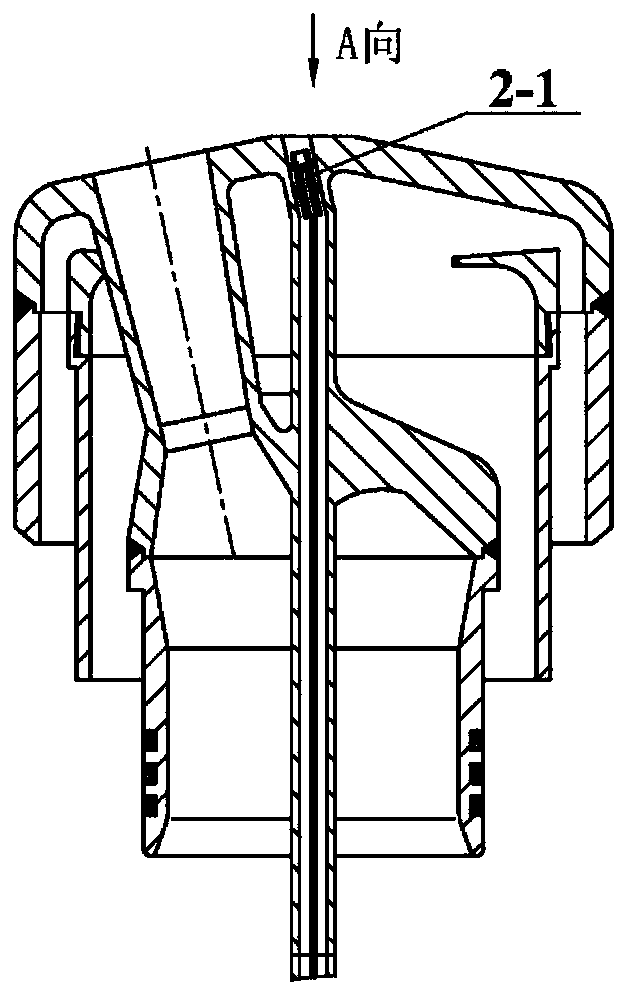

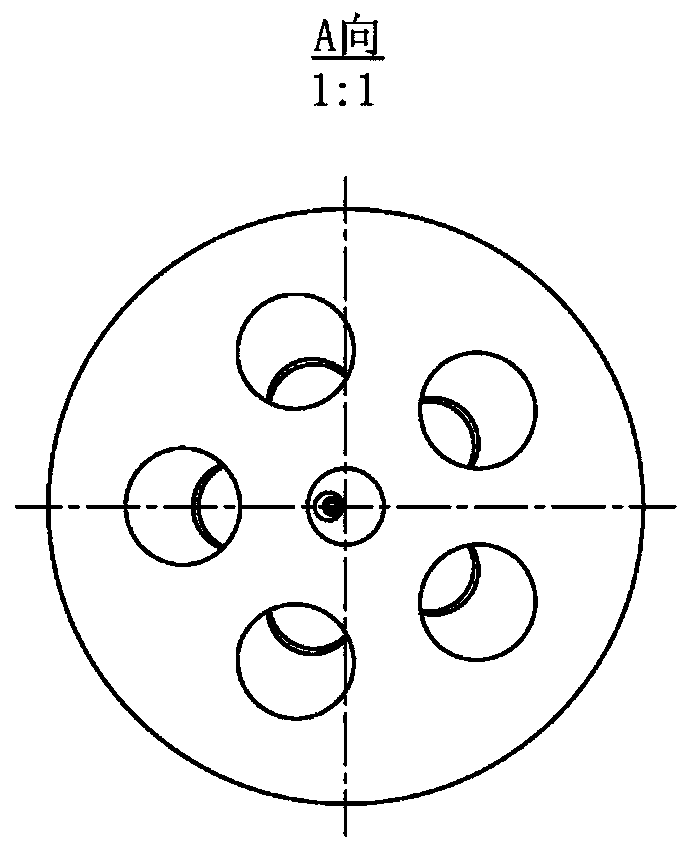

[0032] like figure 1 , figure 2 and image 3 As shown, in this method, an infrared thermometer 2-1 is installed inside the oxygen lance 1, and the infrared thermometer 2-1 is connected to the data processing system 2-2, and the data processing system 2-2 is connected to the smelting secondary system 3, and the smelting secondary system 3 Level system 3 connection CO 2 Flow regulating valve 4-3, O 2 Flow regulating valve 4-4 and oxygen lance control system 5, oxygen lance 1 is connected to thermometer protection system 6 and oxygen lance cooling system 7; CO 2 Flow regulating valve 4-3 is connected to C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com