External scaffold wall connecting structure and construction method

A construction method and technology of load-bearing beams, which are applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve problems such as hindering construction personnel from walking, increasing demolition difficulty, relying on tower cranes, etc., to achieve control of hidden dangers of water seepage and water quality , Avoid the risk of water seepage and water leakage, and reduce the effect of repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

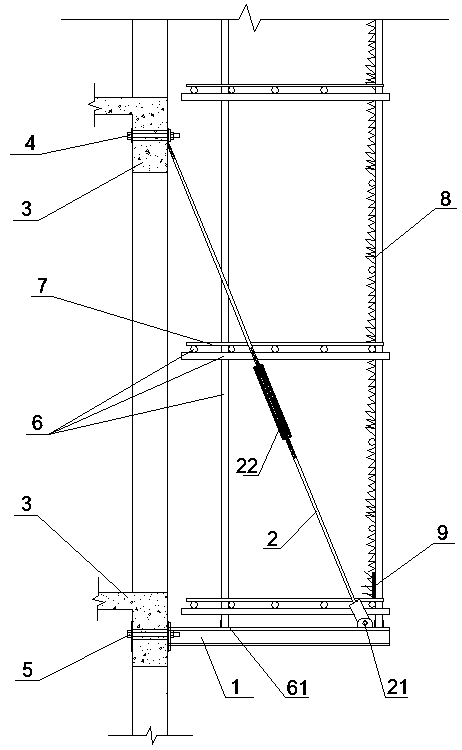

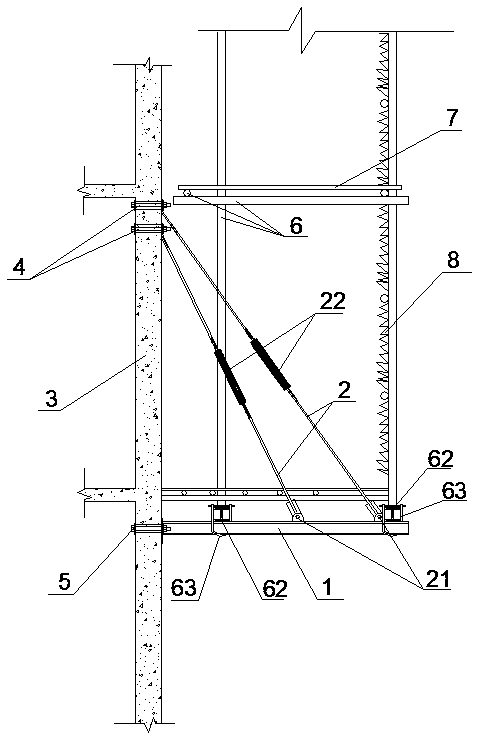

[0032] In combination with the present invention Figure 1-4 The present invention is described in further detail;

[0033] The flower basket cantilevered section steel load-bearing beam structure and construction method include the following construction steps:

[0034] A. According to the requirements of the drawing, pre-embed the tie rod bolt casing and the cantilever bolt casing in the building exterior wall 3, and carry out concrete pouring;

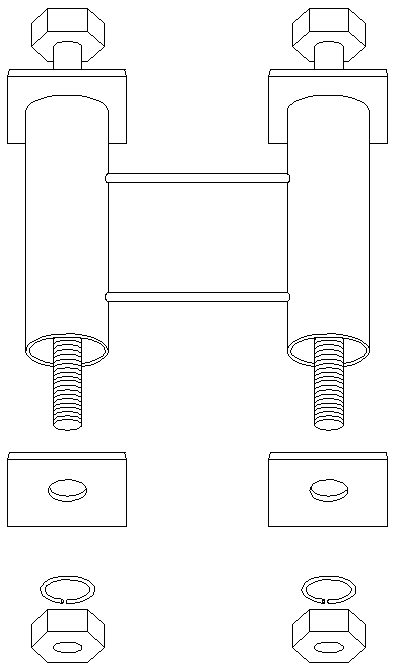

[0035] B. After the pouring of the external wall 3 of the building is completed, lift the cantilevered steel beam 1 and align it with the installation hole and place it. Insert the cantilever bolt assembly 5 into the sleeve and pass through the installation hole of the cantilevered steel beam and tighten it. Tighten the rod bolt assembly 4 Fix the pull rod 2 after fixing, and the other end of the pull rod 2 is fixed on the hanging ear 21 of the cantilevered steel beam 1;

[0036] C. Adjust the turnbuckle screw 22 to tighten the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com