Method for testing heat value of volatile liquid sample

A volatile liquid and testing method technology, applied in the detection field, can solve problems that cannot be solved fundamentally, and achieve the effects of improving detection speed and experimental success rate, simple operation, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0027] In this embodiment, the volatile liquid sample for calorific value test is liquid aviation kerosene.

[0028] During the calorific value test, the device used for encapsulating liquid aviation kerosene is an encapsulating capsule, which is a two-section structure consisting of two parts, the capsule body 1 and the capsule cap 2, which are white and translucent.

[0029] When preparing encapsulated capsules, first take a 10L flask, add 4000g of water, heat it in a water bath to 85°C, and stir for 1min until the temperature of the water in the flask is uniform; then slowly add 850g of hypromellose and 100g of carrageenan in turn while stirring and 100g glycerin, continue to stir and mix for 20min until a uniform glue is formed, then cool to 65°C and keep the temperature for 1h, then dip in the glue and rotate to form a film, dry at 34°C, and demould to prepare capsule body 1 and capsule cap2.

[0030] The calorific value determination method of aviation kerosene specific...

Embodiment ( 2

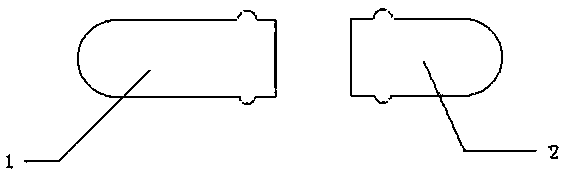

[0039] The encapsulated capsule in this embodiment differs in structure from that of embodiment (1) in that: figure 1 As shown, on the outer side of the capsule body 1, a circumferential semicircular protrusion is set at a distance of 2 mm from the opening, and its outer diameter is 0.5 mm; on the inner side of the capsule cap 2, an axial semicircular groove is set at a distance of 1.5 mm from the opening, and its outer diameter Diameter 0.5mm.

[0040] When preparing encapsulated capsules, first add 3500g of water to a 10L flask, heat it in a water bath to 80°C, and stir for 1min until the temperature of the water in the flask is uniform; then slowly add 750g of hypromellose and 50g of carrageenan in turn while stirring , 20g carrageenan, 10g sorbitol and 40g glycerin, continue to stir and mix for 30min until a uniform glue is formed, then cool to 60°C and keep the temperature for 1.5h, and then use the outer ring 2mm away from the front face to set the outer diameter A 0.5m...

Embodiment ( 3

[0043] The difference with embodiment (two) is:

[0044] Both the protrusion on the outside of the capsule body 1 and the groove on the inside of the capsule cap 2 are semi-elliptical.

[0045] The preparation method of encapsulated capsules: First, add 2500g of water into a 10L flask, heat it in a water bath to 70°C, and stir for 50s until the temperature of the water in the flask is uniform; then slowly add 650g of hypromellose and 30g of fruit Glue, 20g carrageenan, 10g sorbitol, and 50g glycerin, continue to stir and mix for 40min until a uniform glue solution is formed, then cool to 50°C for 0.5h at a constant temperature, and then set an outer ring with a distance of 2mm from the front end. A semi-elliptical convex glass rod with a diameter of 0.5 mm is dipped in glue and rotated to form a film, dried at 40° C., and demolded to obtain a capsule body 1 and a capsule cap 2 respectively.

[0046] Using the encapsulated capsules prepared in this example, according to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com