Mildew-proof multi-layer eucalyptus board and production method thereof

A production method and technology for wood boards, which are applied in the joining, coating, wood processing appliances and other directions of wooden veneers, can solve the problems of inability to guarantee product formaldehyde exceeding the standard, uneven sizing, easy deformation of products, etc., and reduce volatility. The effect of formaldehyde, small shrinkage and swell rate, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

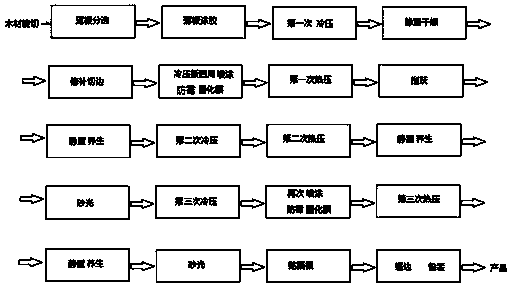

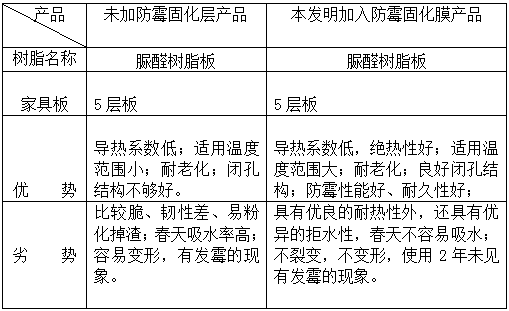

[0042] A method for producing mildew-proof multi-layer eucalyptus wood boards, the production method of the multi-layer boards includes veneer veneer sorting, veneer gluing, three times of cold pressing, three times of hot pressing, second standing for health preservation, dust scraping, sanding, and repairing 1. The step of trimming and pasting panels, characterized in that: before the first cold pressing, trimming, the first hot pressing and the last hot pressing, a layer of anti-mildew curing film is sprayed around and up and down the surface of the slab, Protect the glue from drying too quickly during the hot pressing process, and maintain the internal stress of the multi-layer board. It can also make the urea-formaldehyde glue fully react, so that the strength of the multi-layer board after molding is high, and the volatile formaldehyde is reduced during the user's use. After the third hot pressing, the boards are left to stand for health preservation, sanded and veneered,...

Embodiment 2

[0049] A method for producing mildew-proof multi-layer eucalyptus wood boards, the production method of the multi-layer boards includes veneer veneer sorting, veneer gluing, three times of cold pressing, three times of hot pressing, second standing for health preservation, dust scraping, sanding, and repairing 1. The step of trimming and pasting panels, characterized in that: before the first cold pressing, trimming, the first hot pressing and the last hot pressing, a layer of anti-mildew curing film is sprayed around and up and down the surface of the slab, Protect the glue from drying too quickly during the hot pressing process, and maintain the internal stress of the multi-layer board. It can also make the urea-formaldehyde glue fully react, so that the strength of the multi-layer board after molding is high, and the volatile formaldehyde is reduced during the user's use. After the third hot pressing, the boards are left to stand for health preservation, sanded and veneered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com