A light-to-heat conversion material and its preparation method and application

A photothermal conversion, double-layer structure technology, applied in chemical instruments and methods, general water supply saving, synthetic resin layered products, etc., can solve the problems of high cost of photothermal conversion materials, low solar photothermal conversion efficiency, etc. The effect of improving photothermal conversion efficiency, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

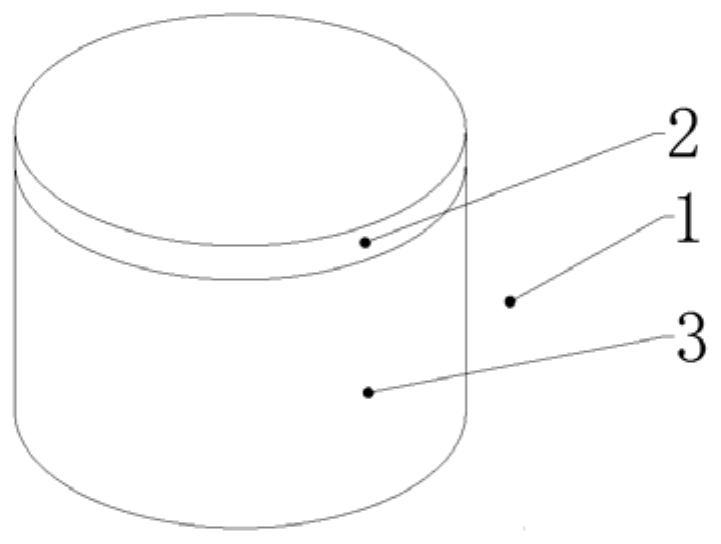

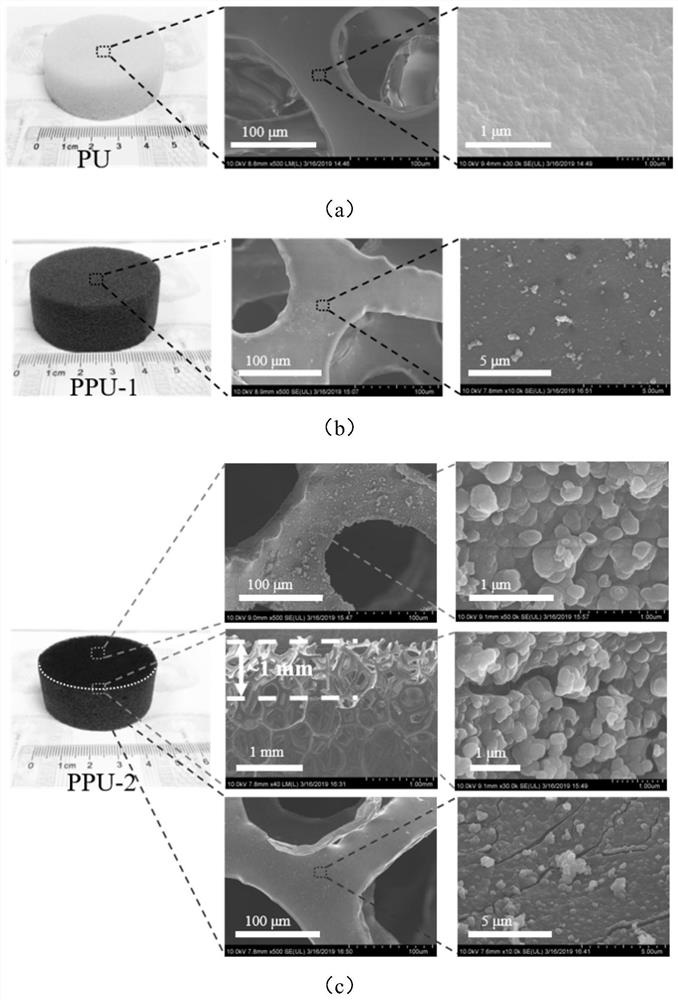

[0056] Such as figure 1 and figure 2 As shown in the middle figure (c), the light-to-heat conversion material is a polydopamine heterogeneously modified polyurethane sponge 1, and the polydopamine heterogeneously modified polyurethane sponge 1 has a double-layer structure, and the top layer of the double-layer structure The concentration of polydopamine in 2 is higher than the concentration of polydopamine in the bottom layer 3 of the double-layer structure, the top layer 2 of the double-layer structure is dark black, the thickness of the top layer 2 is 1.0 mm, and the double-layer structure 1 The total thickness is 20mm.

[0057] Wherein, the density of described polyurethane sponge is 0.2g / cm 3 , the porosity is 70%, the pore diameter is 50μm, and the specific surface area is 2.48m 2 / g.

[0058] Wherein, the load of polydopamine is 24.6mg.

[0059] The preparation method of the light-to-heat conversion material comprises the following steps:

[0060] S1. Purifying po...

Embodiment 7

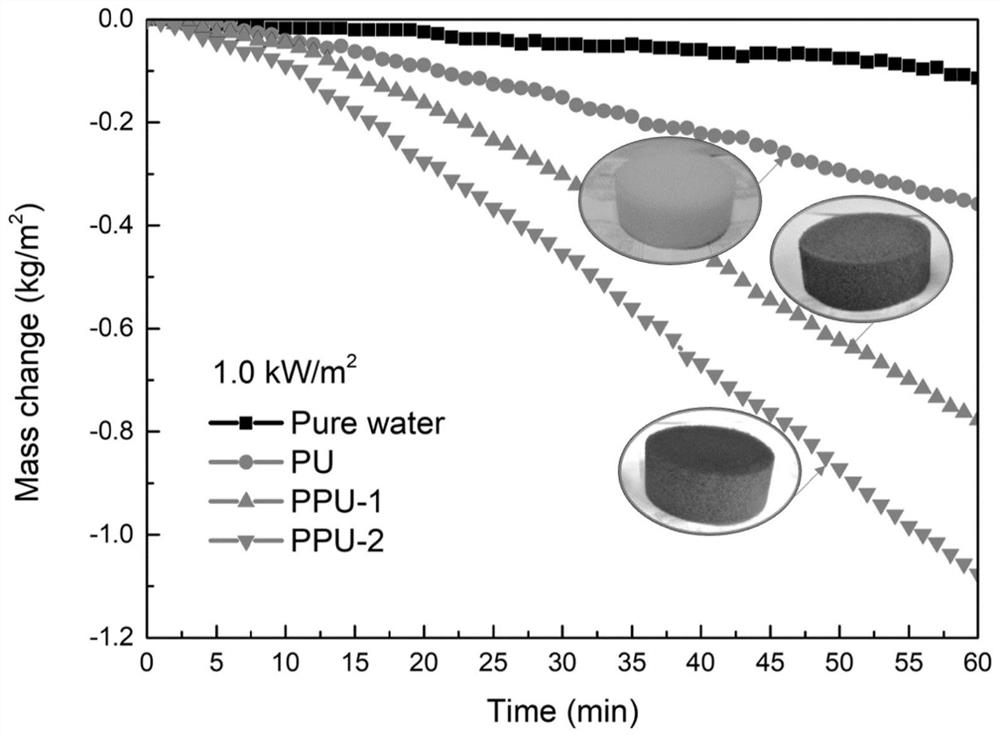

[0079] The double-layer modified sponge (PPU-2) is put into 150ml of filling, in the beaker of 3.5wt% salt water, press sponge in 3.5wt% salt water, make whole piece of sponge absorb water completely, and float on the water surface, then in by Under the broadband solar radiation provided by the solar simulator, it is equipped with adjustable components to control 1.0, 1.5, 2.0, 2.5 suns (1.0, 1.5, 2.0, 2.5kW / m 2 ). The solar intensity was measured with a photoradiometer, and the mass change of the water in the beaker was measured in real time with an electronic calibration balance.

[0080] Such as Figure 4 As shown, it is observed that under different solar irradiations, the photothermal conversion efficiency of solar steam is 86.1%, 91.3%, 92.2%, and 93.3%, respectively.

[0081] Compared with the prior art, there is no agitation and the container is not covered, so that the solution is in full contact with the air, and under the oxidation of sufficient oxygen, more dopam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com