Aerodynamic glass insulator and manufacturing method thereof

A glass insulator, aerodynamic technology, applied in insulators, electrical components, coatings, etc., can solve the problems of reduced insulation level, creeping breakdown, strong discharge and other problems of insulators, to improve uniformity and stability, avoid aggregation, improve The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

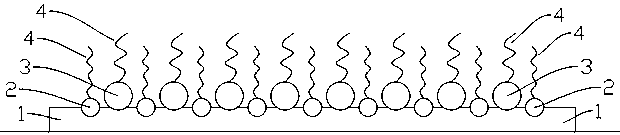

[0038] as attached figure 1 As shown, an aerodynamic glass insulator is provided with a coating on its surface, and the coating includes at least four layers from bottom to top, the first layer is fluorocarbon resin 1, and the second layer is nano-silica particles 2 , the third layer is nano-calcium carbonate particles 3, the fourth layer is long-chain silane 4, the bottom surface of the fluorocarbon resin 1 is bonded to the surface of the insulator, and the bottom of the nano-silica particles 2 is embedded in the fluorocarbon resin 1 The bottom of the nano-calcium carbonate particle 3 is embedded in the nano-silica particle 2, the head of the long-chain silane 4 is connected to the nano-calcium carbonate particle 3 or the nano-silica particle 2, and the tail of the long-chain silane 4 is extended outside.

Embodiment 2

[0040] On the basis of Example 1, the particle size of the nano silicon dioxide particles is 30nm to 90nm.

[0041] The particle size of the nano calcium carbonate particles is 200nm to 500nm.

[0042] The long-chain silane is one or more of heptadecafluorodecyltriethoxysilane, heptadecafluorodecyltrimethoxysilane, tridecafluorooctyltriethoxysilane, tridecafluorooctyltrimethoxysilane kind of mix.

Embodiment 3

[0044] On the basis of Example 1, the particle size of the nano silicon dioxide particles is 30nm.

[0045]The particle size of the nano-calcium carbonate particles is 200nm.

[0046] The long chain silane is a mixture of heptadecafluorodecyltriethoxysilane and heptadecafluorodecyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com