Graphene composite impact-resistant anti-static environment-friendly coating material and preparation method thereof

A coating material and anti-static technology, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of low anti-static and impact resistance, unable to meet the needs of enterprises, and achieve good affinity, Improve health damage and environmental pollution, the effect of reasonable curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

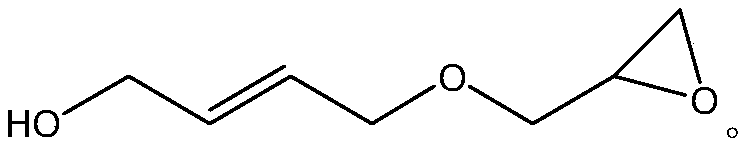

[0028] As a preferred embodiment, the epoxy resin is bisphenol A epoxy resin;

[0029] Preferably, the bisphenol A epoxy resin is polyimide modified bisphenol A epoxy resin.

[0030] The preparation method of the bisphenol A type epoxy resin modified by polyimide comprises the steps:

[0031] (1) Preparation of polyimide: 2.13g of 4,6-diaminoresorcinol hydrochloride (DAR, CAS No. 16523-31-2) and 1mL of triethylamine were dissolved in 25mL of N-methyl Add 3.1g of diphenyl ether tetracarboxylic dianhydride (CAS No. 50662-95-8), 10mL of toluene and 1.0g of glacial acetic acid to the base pyrrolidone, then raise the temperature to 180°C and keep it for 5 hours. Precipitate in methanol, filter and dry in vacuo to obtain polyimide.

[0032] (2) the polyimide, norbornene diacid anhydride, 2,4,6-tri( Dimethylaminomethyl) phenol was mixed, stirred while heating, heated to 120° C. for 1 hour, and then heated to 150° C. for 3 hours to obtain a polyimide-modified bisphenol A epoxy resi...

Embodiment 1

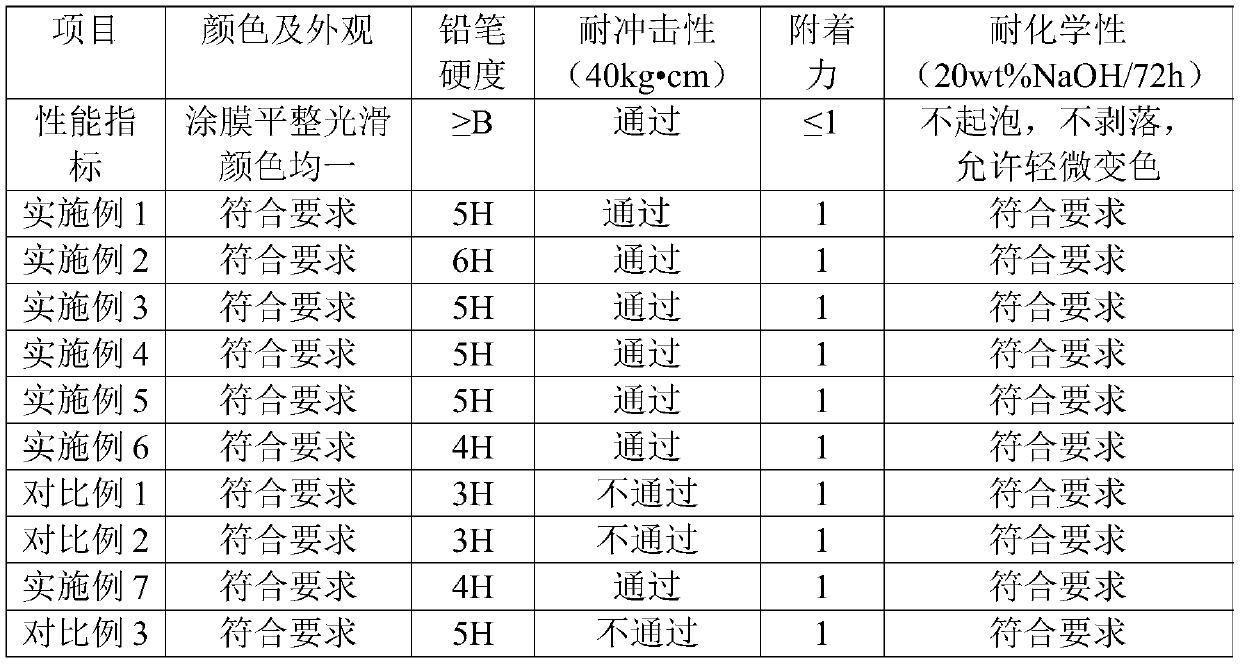

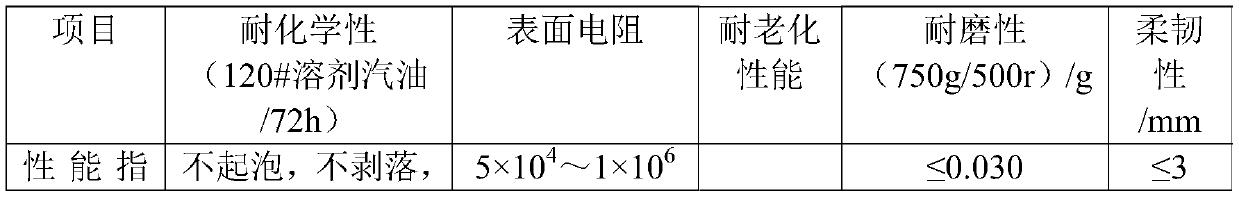

[0104] An impact-resistant, anti-static and environment-friendly coating material, which is composed of two components, A and B. In parts by weight, the A component includes the following raw materials: 55 parts of epoxy resin, 12 parts of color paste, 33.5 parts of colored sand parts, 5 parts of monoepoxy glycidyl ether, 8.5 parts of fillers, 1.8 parts of defoamers, and 0.7 parts of leveling agents; the B component includes 55 parts of aminophenyl compounds.

[0105] Described epoxy resin is the bisphenol A type epoxy resin of polyimide modification, and the preparation method of the bisphenol A type epoxy resin of described polyimide modification comprises the steps:

[0106] (1) Preparation of polyimide: Dissolve 2.13g of 2,4-dihydroxy m-phenylenediamine hydrochloride and 1mL of triethylamine in 25mL of N-methylpyrrolidone, add 3.1g of diphenyl ether tetra Carboxylic acid dianhydride (CAS No. 50662-95-8), 10mL of toluene and 1.0g of glacial acetic acid, then heated to 180°C...

Embodiment 2

[0136] An anti-shock, anti-static and environment-friendly coating material, which is composed of two components, A and B. In parts by weight, the A component includes the following raw materials: 45 parts of epoxy resin, 9 parts of color paste, 14 parts of colored sand 3 parts, 3 parts of monoepoxy glycidyl ether, 6 parts of filler, 1 part of defoamer, 0.1 part of leveling agent; the B component includes 45 parts of aminophenyl compounds.

[0137] The epoxy resin is a polyimide-modified bisphenol-A epoxy resin, and the preparation method of the polyimide-modified bisphenol-A epoxy resin is the same as in Example 1.

[0138] The color paste was purchased from Dongguan Beinu Composite Materials Co., Ltd.

[0139] The colored sand is a mixture of epoxy resin sand containing modified graphene oxide and resin colored sand, 4 parts of epoxy resin sand containing modified graphene oxide, and 10 parts of resin colored sand.

[0140]The resin colored sand was purchased from Shanghai ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com