Extremely thermophilic bacteria and application thereof in high-temperature composting fermentation

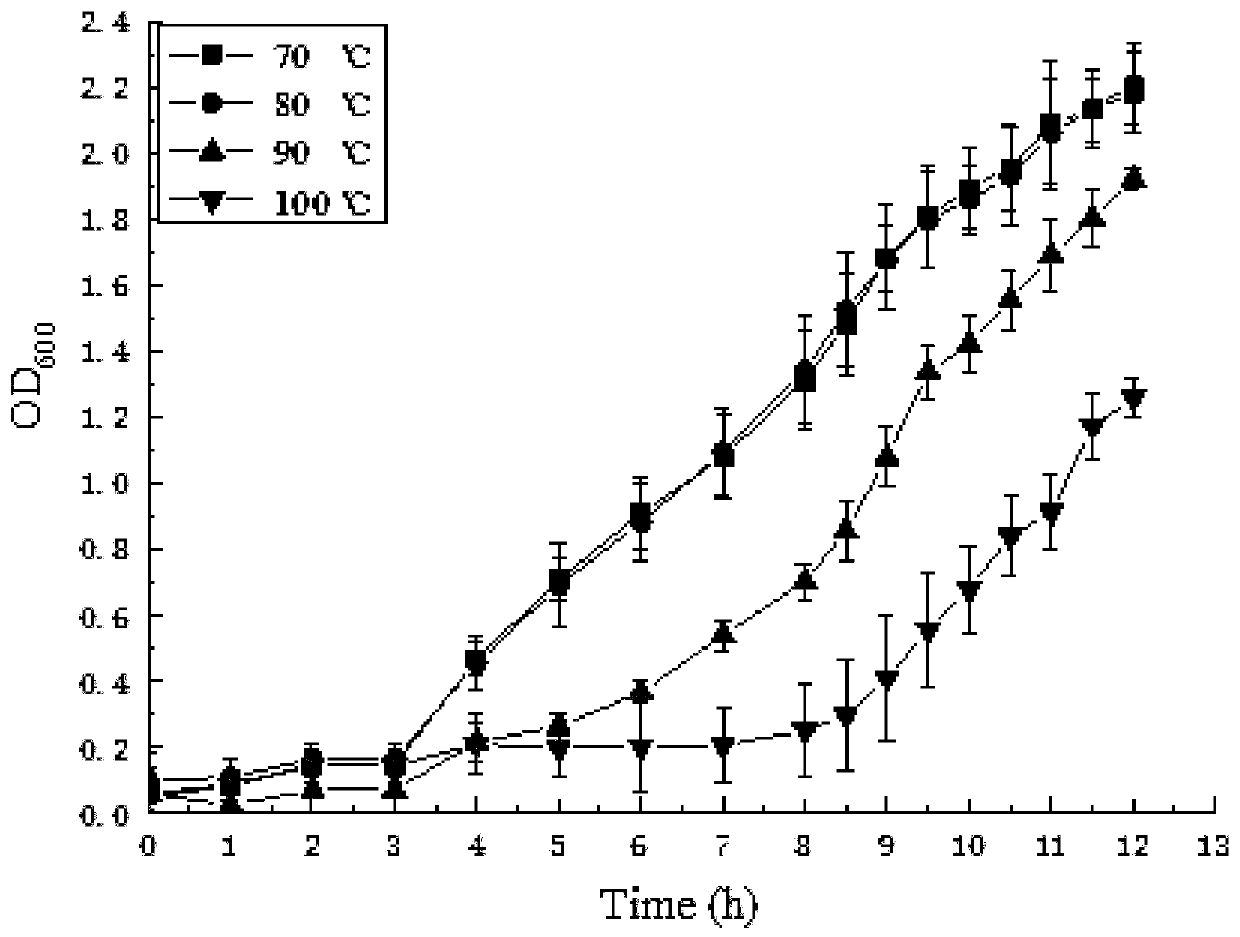

A kind of thermophilic and bacterial technology, which is applied in the field of microbial technology and environmental engineering, can solve the problems of shortage and difficulty in reaching a higher fermentation temperature, and achieve the effects of saving time and cost, accelerating putrefaction, and increasing compost temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Food waste composting treatment

[0057] Take 5 tons of food waste, cut and stir to make it into pieces with a diameter of about 3cm. Put the pieces into the fermentation device, add 3% quicklime, 0.5g esterase, 0.8g cellulase, 0.4g alkaline amylase, 0.5g alkaline protease, control the moisture content of the material at about 80%, and stir evenly Then stand still for 0.5h. Then put 1.5 tons of GW-2 bacterial agent into the fermenter (when making, the volume ratio of fermentation broth to dry wood chips is 1:0.9), stir evenly and start heating. After 0.5h, the temperature in the fermenter reaches 45°C. After maintaining the heating for 3 hours, the temperature rises to 60°C, the heating is stopped, and the high-temperature composting stage is entered at this time. After 20 hours, the temperature rose to 100°C and the humidity dropped to 75%. After 24 hours, the temperature in the fermenter began to decrease slowly, and dropped to 60°C after 44 hours. At...

Embodiment 2

[0058] Example 2: Farming solid waste composting

[0059] Take 10 tons of pig farm feces, put in 4.5% quicklime, stir evenly, control the moisture content of the material at 82%, put in 0.8g esterase, 1.3g cellulase, 0.3g alkaline amylase, 0.8g alkaline protease and continue Mix and stir, turn on the electric heating to raise the temperature to 45°C and maintain it for 1h. Put in 4 tons of GW-2 bacterial agent sawdust, (during production, the volume ratio of fermentation liquid to dry sawdust is 1:0.8), stir well, increase the electric heating power to raise the temperature to 45°C, and start high-temperature composting. After 4 hours of start-up, the temperature of the compost heap rose to 65°C, and gradually increased within 24 hours of start-up, and finally reached 85-100°C, and the humidity gradually decreased from the initial 80% to about 53%. Then the temperature dropped slowly, and the temperature dropped to 65°C within 48 hours of starting. At this time, 20% of the vo...

Embodiment 3

[0060] Example 3: Fertilizer composting of agricultural by-products

[0061] Take 5 tons of straw, add it to the fermentation device with cutting and stirring, and continuously cut and stir it into pieces of about 6cm, put in 5% quicklime, stir evenly, control the moisture content of the material at 85%, put in 0.7g esterase, 1.3g cellulase , 0.6g alkaline amylase, and 0.5g alkaline protease continued to mix and stir, and turned on the electric heating to raise the temperature to 45°C and maintain it for 2h. Put in 2.5 tons of GW-2 bacterial agent sawdust, (during production, the volume ratio of fermentation liquid to dry sawdust is 1:1), stir well, increase the electric heating power to raise the temperature to 45°C, and start high-temperature composting. After 4 hours of start-up, the temperature of the compost heap rose to 60°C, and gradually increased within 24 hours of start-up, and finally reached 85-100°C, and the humidity gradually decreased from the initial 87% to abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com