An assembled ecc-photovoltaic power generation surface structure and construction method

A photovoltaic power generation and pavement structure technology, applied in photovoltaic power generation, photovoltaic modules, roads, etc., can solve problems such as low efficiency, high difficulty, and unreasonable stress on the structural layer, so as to improve economy, improve service life, and achieve large The effect of area mechanized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

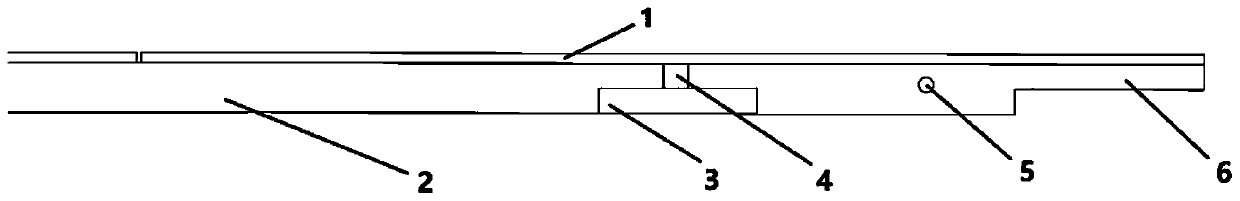

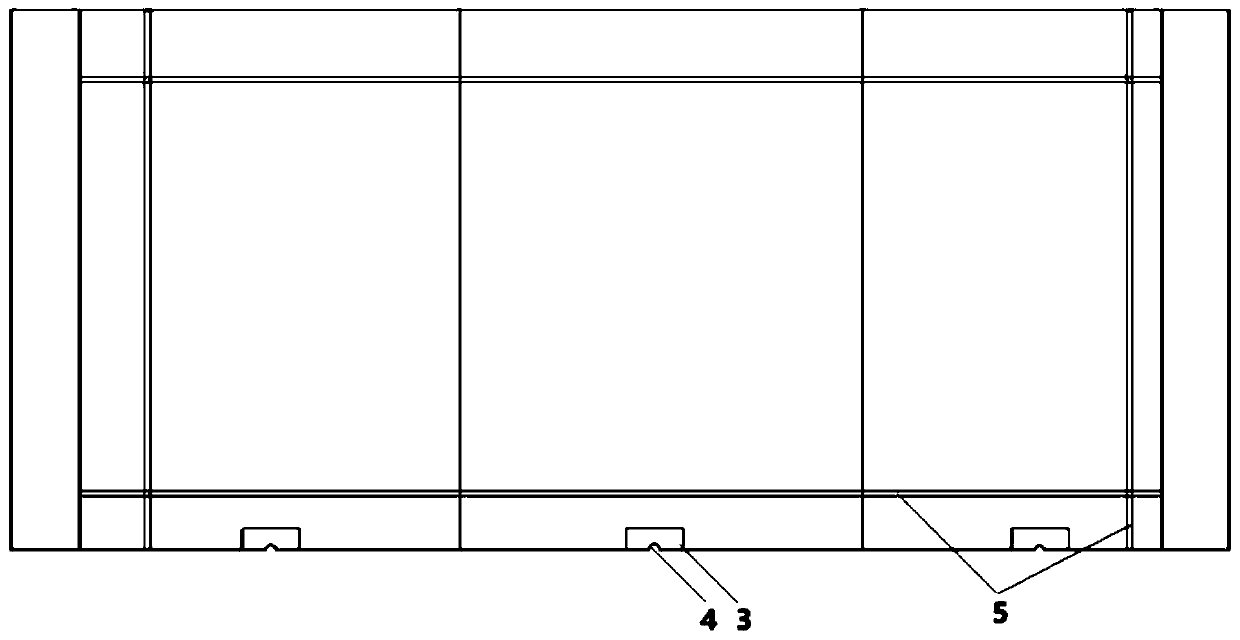

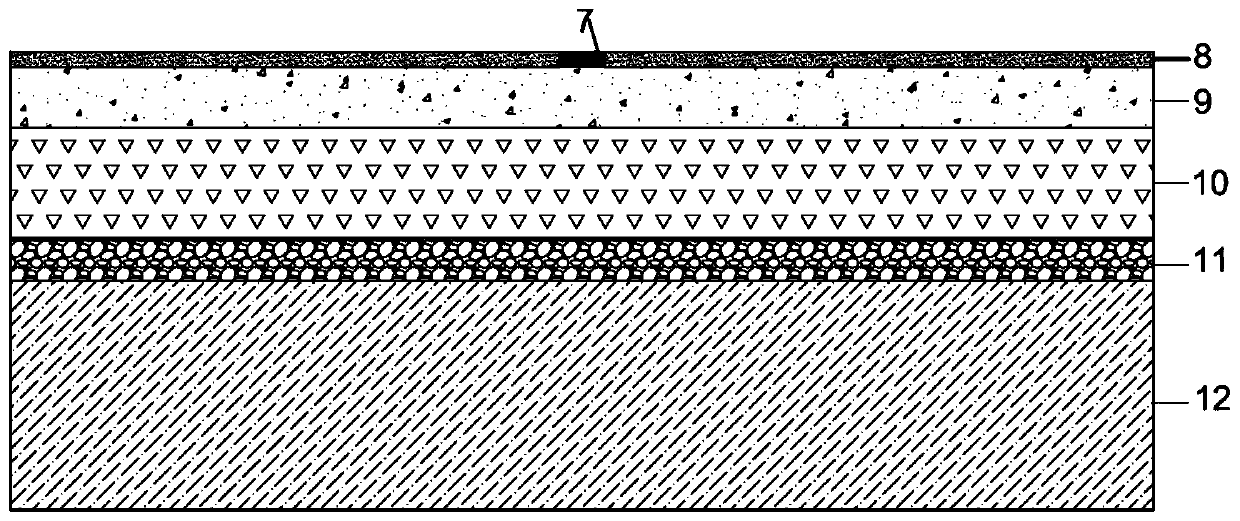

[0049] In a typical implementation of the present application, such as figure 1 , figure 2 , image 3 As shown, a prefabricated ECC-cement concrete photovoltaic power generation surface structure at least includes: roadbed 12, base layer 10, surface layer 9 and photovoltaic power generation functional layer 8 arranged sequentially from bottom to top.

[0050] The roadbed 12 can be a soil roadbed that meets the requirements of my country's "Highway Roadbed Design" (JDGD30). The roadbed should be stable, compact and homogeneous, and can provide uniform support for the road surface structure; Subgrade Construction Technical Specifications (JTJF10).

[0051] The base 10 can be cement stabilized aggregate, roller compacted concrete or lean concrete base, and should have sufficient anti-scourability and certain rigidity. Its design thickness should comply with the "Code for Design of Cement Concrete Pavement" (JDGD40). Depending on the road grade or traffic volume, one or two lay...

Embodiment 2

[0063] This embodiment discloses a construction method based on the assembled ECC-cement concrete photovoltaic surface structure disclosed in Embodiment 1, as follows:

[0064] 1 The specific steps of prefabrication of prefabricated plate units are as follows:

[0065] (1) Weigh various materials according to the ECC mix ratio in Table 1 below, and then add them to the concrete mixer in turn and mix them evenly. The mixing sequence is: add cement, fly ash, quartz sand, and thickener to the mixer for dry mixing for 3 minutes, then add water mixed with water reducing agent in advance and stir again for 5 minutes, until the water reducing agent fully exerts its effect and the slurry When the fluidity of the resin is good, gradually add PVA fiber, and the process is completed within 6 minutes.

[0066] Table 1 ECC mix ratio

[0067]

[0068]

[0069] (2) After the materials are evenly stirred, pour the ECC into the formwork prepared in advance. In order to ensure that the ...

Embodiment 3

[0086] According to the process of embodiment 2, the photovoltaic pavement is laid, and when the pavement is damaged and needs to be repaired, the implementation steps are as follows:

[0087] If the panel unit is damaged, loses road function or power generation function and needs to be replaced, the damaged panel can be removed and a new panel unit can be replaced, and the circuit connection there can be restored. Specific steps are as follows:

[0088] 1. The prefabrication process of the panel unit is the same as that in Example 1

[0089] 2. Remove the damaged plate unit in the road, and be careful not to damage the connected circuit in the pipeline ditch. Mortar and other materials can be used to re-level the lower cement concrete layer.

[0090] 3. Transport the prefabricated plate units in the factory to the repair site, and adopt the form of overlapping with the adjacent plate units, and bond with the cement concrete surface layer through the adhesive to form a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com