Underwater thick powder fine sand layer pore-forming expanding and stirring device and pore-forming method using same

A silt fine sand, hole-forming technology, applied in earthwork drilling, drilling equipment, infrastructure engineering, etc., can solve problems such as poor hole wall stability and over-limit sediment at the bottom of the hole, so as to reduce resistance and soil confining pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

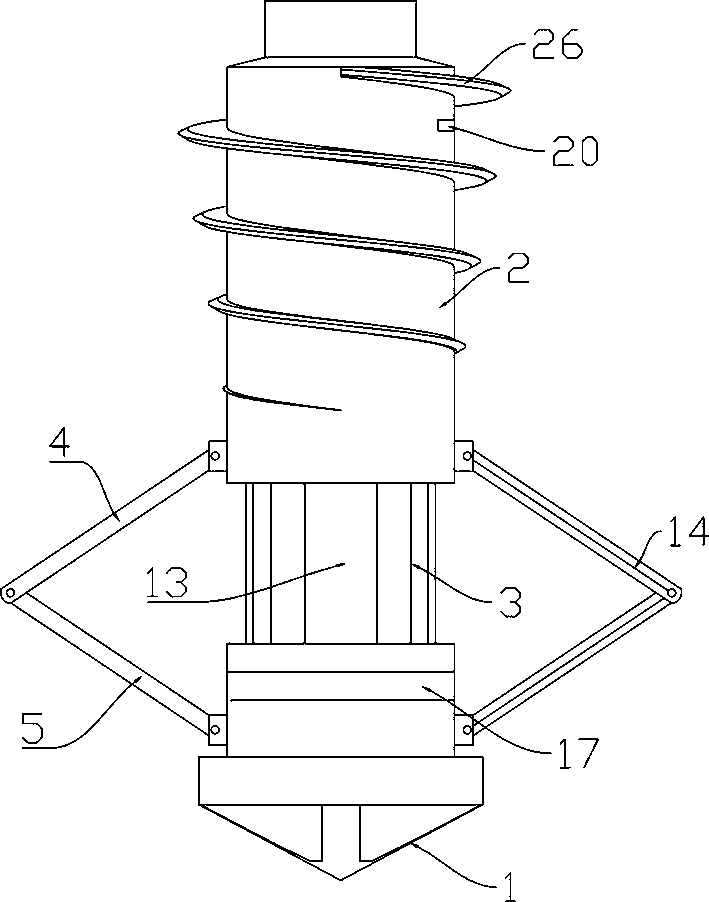

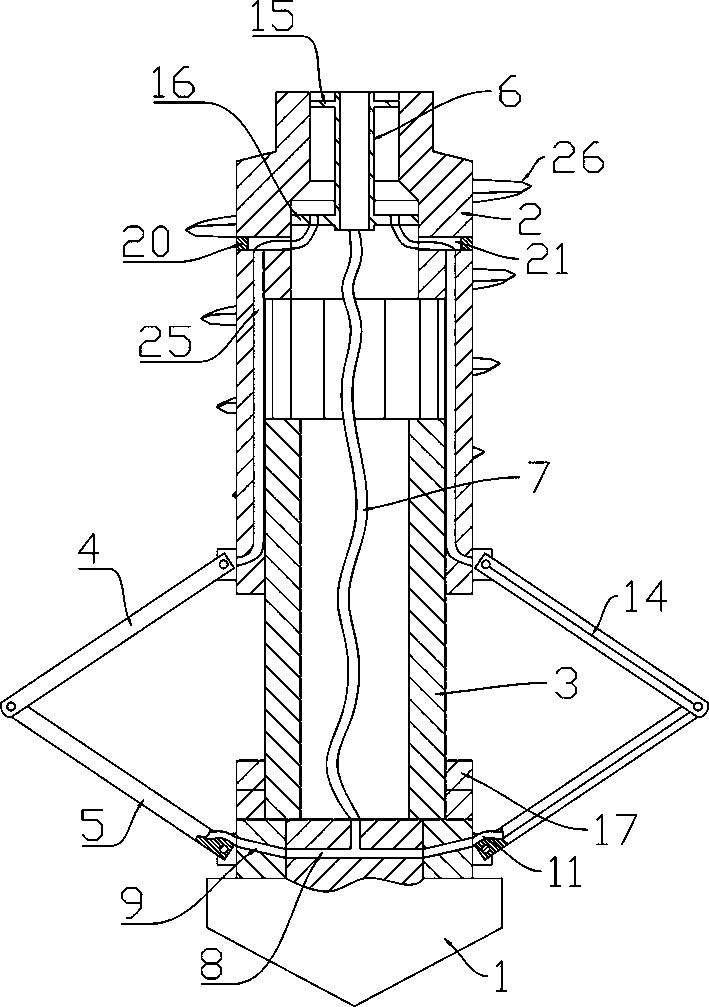

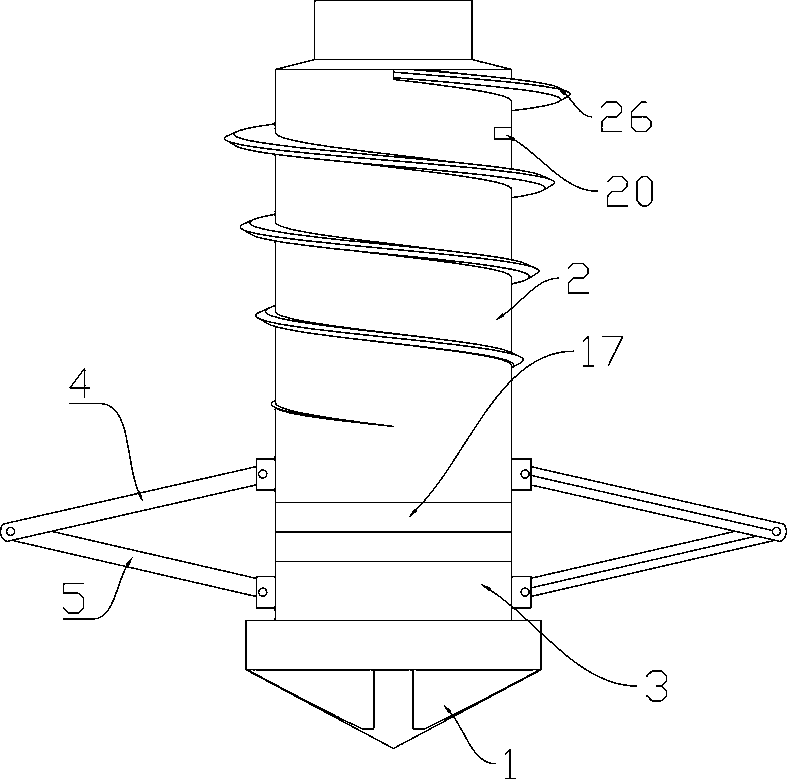

[0062] Such as Figure 1~6 As shown, a kind of expansion agitator for underwater thick silt and fine sand layer pore forming includes a pipe body, a drill bit 1, a cutting and stirring frame and a slurry delivery system, and the pipe body includes an outer pipe 2 and an inner pipe 3, and the outer pipe body includes an outer pipe 2 and an inner pipe 3. The pipe 2 is a steel pipe with an inner diameter of 20-40 cm, a wall thickness of 3-5 cm, and a length of 50-100 cm. The upper end of the outer pipe 2 is threadedly connected with a double-tube drill pipe with a core pipe. The helical blade 26, the lower part of the outer tube 2 is fitted with an inner tube 3, specifically, the inner wall of the outer tube 2 is provided with several guide grooves, and the outer wall of the inner tube 3 is provided with a protrusion 13 at the position corresponding to the guide groove, the guide groove and The protrusions 13 match and enable the outer tube 2 and the inner tube 3 to slide against...

Embodiment 2

[0079] The method of forming holes in thick silt and fine sand under diving conditions (the method of drilling a hole with a self-made retaining ring), including the following steps:

[0080] Step 1: According to the properties of the silty sand 22 and the thickness of the retaining ring 18 to be installed, calculate the size of the expansion and agitation range and the elevation of the top and bottom.

[0081] Step 2: Determine the size of the expander, including the height and diameter of the outer tube 2 and inner tube 3, the size of the cone tip angle of the drill bit 1 and the size of the cutting and stirring frame. Usually, when the cutting and stirring frame is closed, the diameter of the outer envelope circle of the expander is 1 / 3 to 2 / 3 of the drilling diameter to select the diameter of the inner tube 3 and the outer tube 2, and when the cutting and stirring frame is fully opened, the slurry outlet hole 12 The length of the upper cutting plate 4 and the lower cutting...

Embodiment 3

[0093] The method for forming holes in thick silt and fine sand under the condition of high-pressure water bearing (self-made slurry-soil retaining wall forming method), including the following steps:

[0094] Such as Figures 13 to 18 as shown,

[0095] The steps of this embodiment are basically the same as those in Embodiment 2, and the similarities will not be described in detail. The difference is:

[0096] In step 1, the initial elevation of expansion and stirring is selected above the lowest elevation that does not produce hole bottom inrush, and the inrush safety factor is taken as 1.05, that is, the pressure of wall retaining mud 23 in the hole and the top of silty sand layer 22 and the initial elevation of expansion and agitation The sum of the self-weight of the soil layers in between is greater than 1.05 times the pressure of the confined water head.

[0097] The helical blade 26 of the supporting drill pipe selected in step 3 is 20-50 cm smaller than the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com