Method and system for extracting sludge protein by focused pulsed electric field

A pulsed electric field and sludge protein technology, applied in the field of sludge resource utilization, can solve the problems of easy side reactions, low extraction rate, and waste of chemical reagents, and achieve the effects of easy production, durability, improved efficiency, and precise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

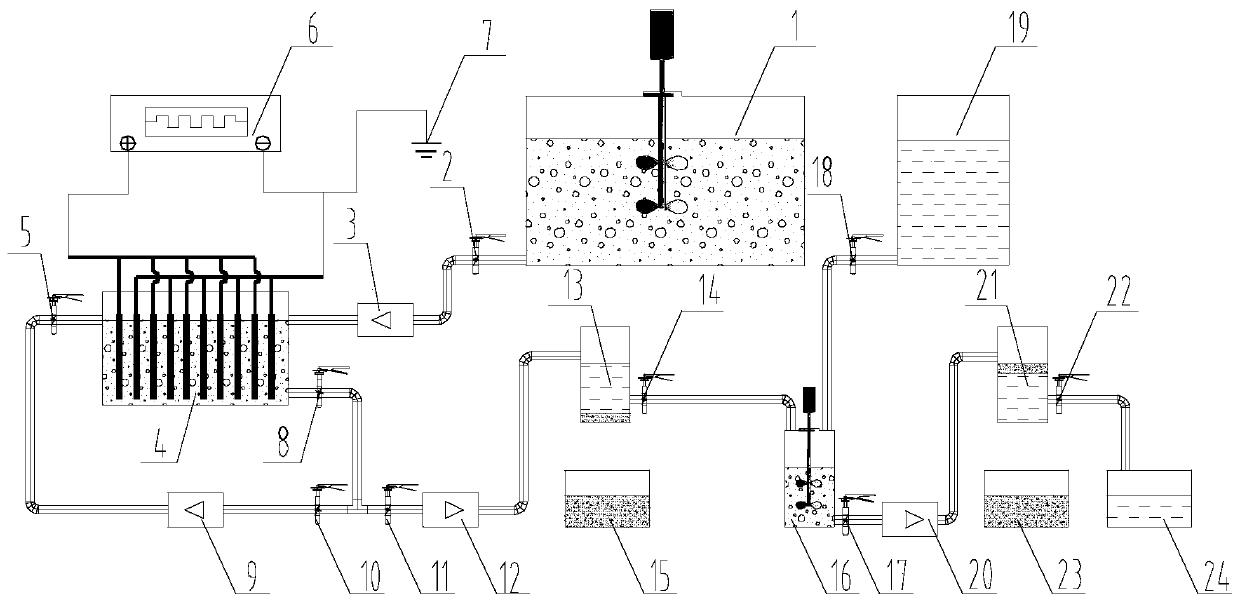

[0031] figure 1 It is a schematic diagram of the system for extracting sludge protein by focused pulsed electric field. Such as figure 1 As shown, the system for extracting sludge protein by focused pulse electric field includes: sludge homogeneous mixing system 1, first valve 2, feed pump 3, focused pulse electric field sludge reactor 4, second valve 5, high-voltage pulse generator power supply 6 , safety grounding 7, third valve 8, circulating pump 9, fourth valve 10, fifth valve 11, sludge disposal pump 12, high-speed centrifuge 13, sixth valve 14, sludge residue tank 15, pH adjustment tank 16. Seventh valve 17, eighth valve 18, pH regulator 19, protein liquid transfer pump 20, refrigerated vacuum belt filter 21, ninth valve 22, protein storage tank 23, waste liquid storage tank 24.

[0032]When extracting protein from sludge: first adjust the sludge to a flowable state in the sludge homogeneous mixing system 1, the ratio of sludge to distilled water is 1:1~1:2; after hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com