Ethanol recovery and heat utilization method

A technology of ethanol and heat, applied in chemical instruments and methods, preparation of organic compounds, sustainable manufacturing/processing, etc., can solve problems such as high energy consumption of separation and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

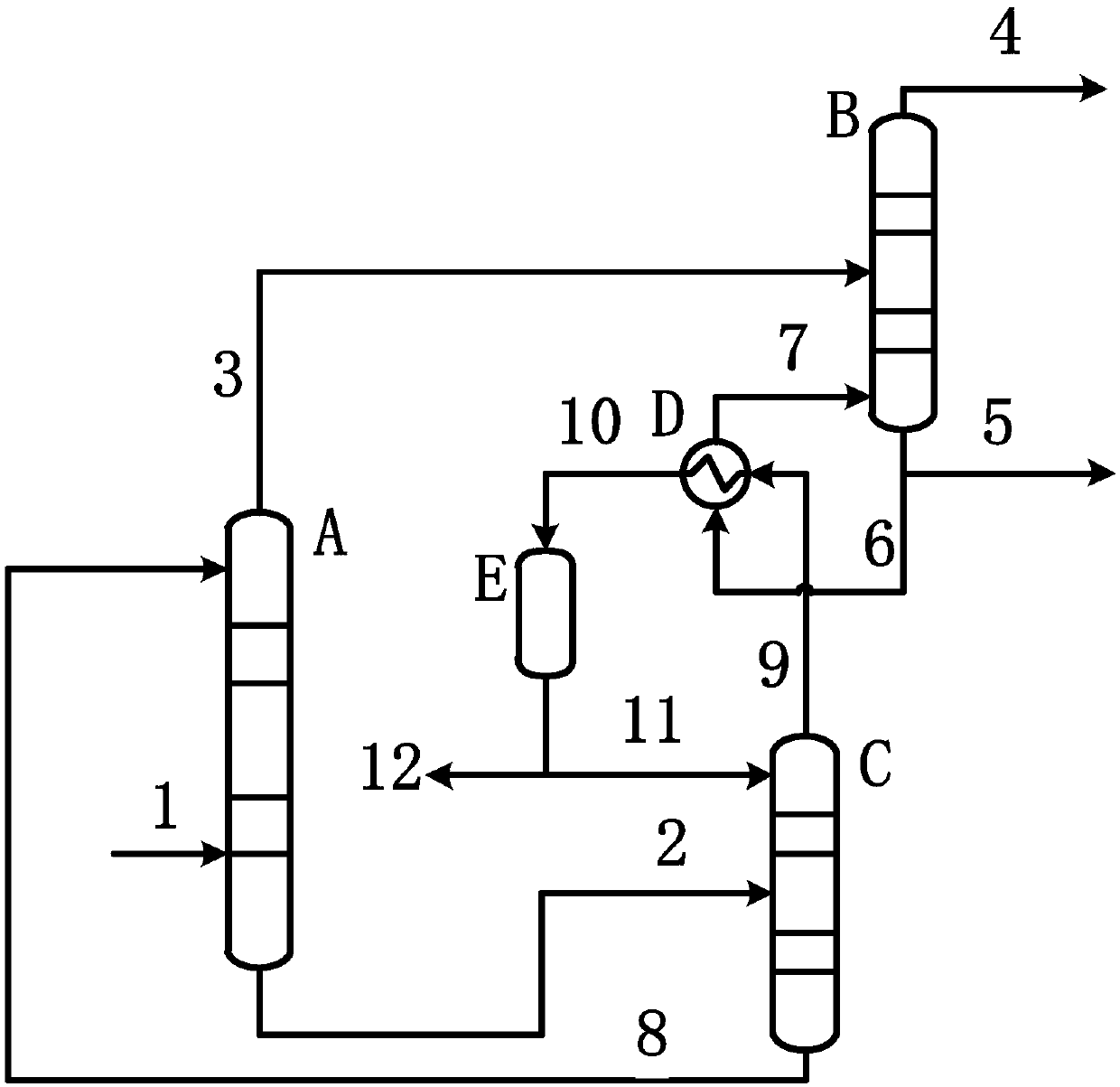

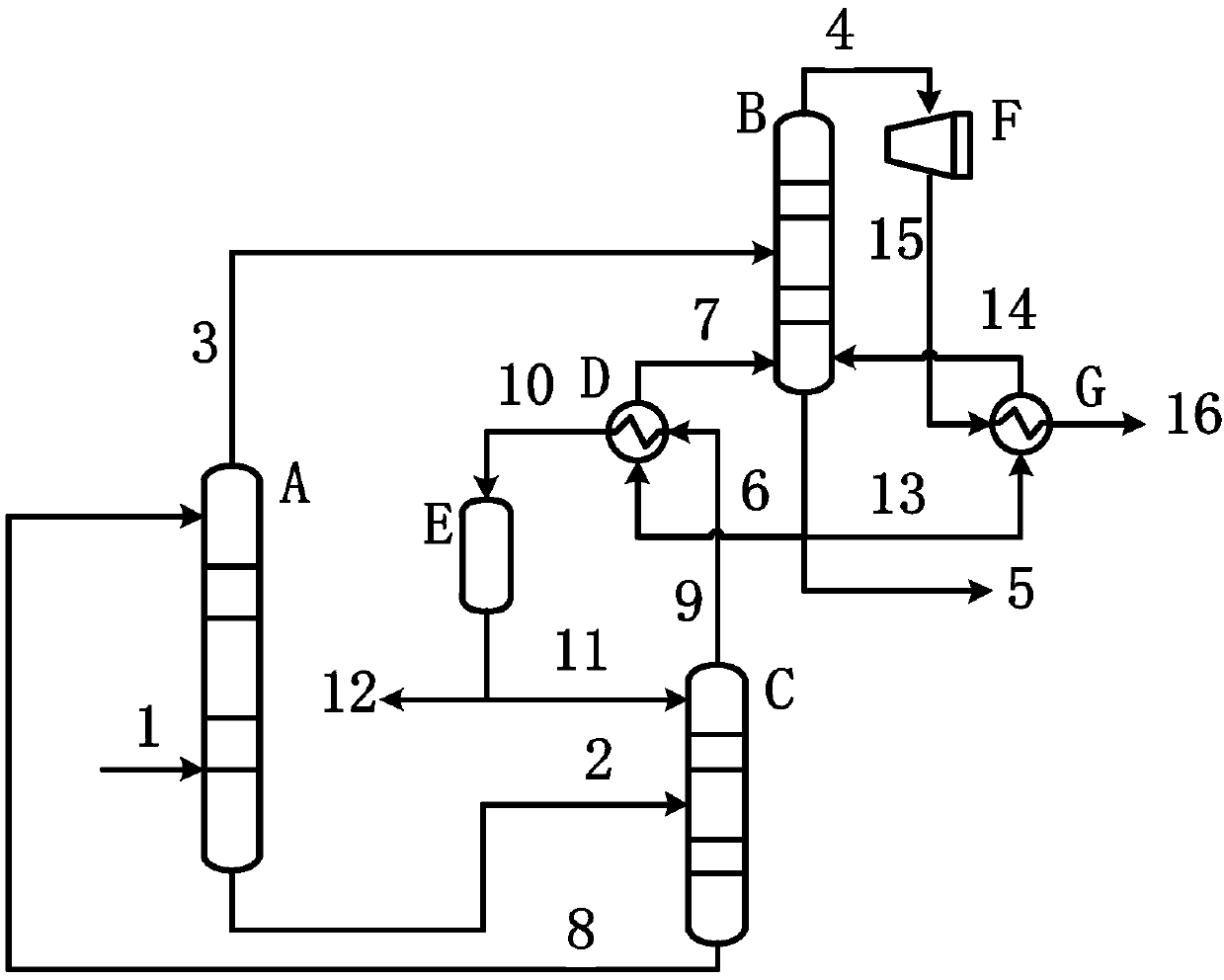

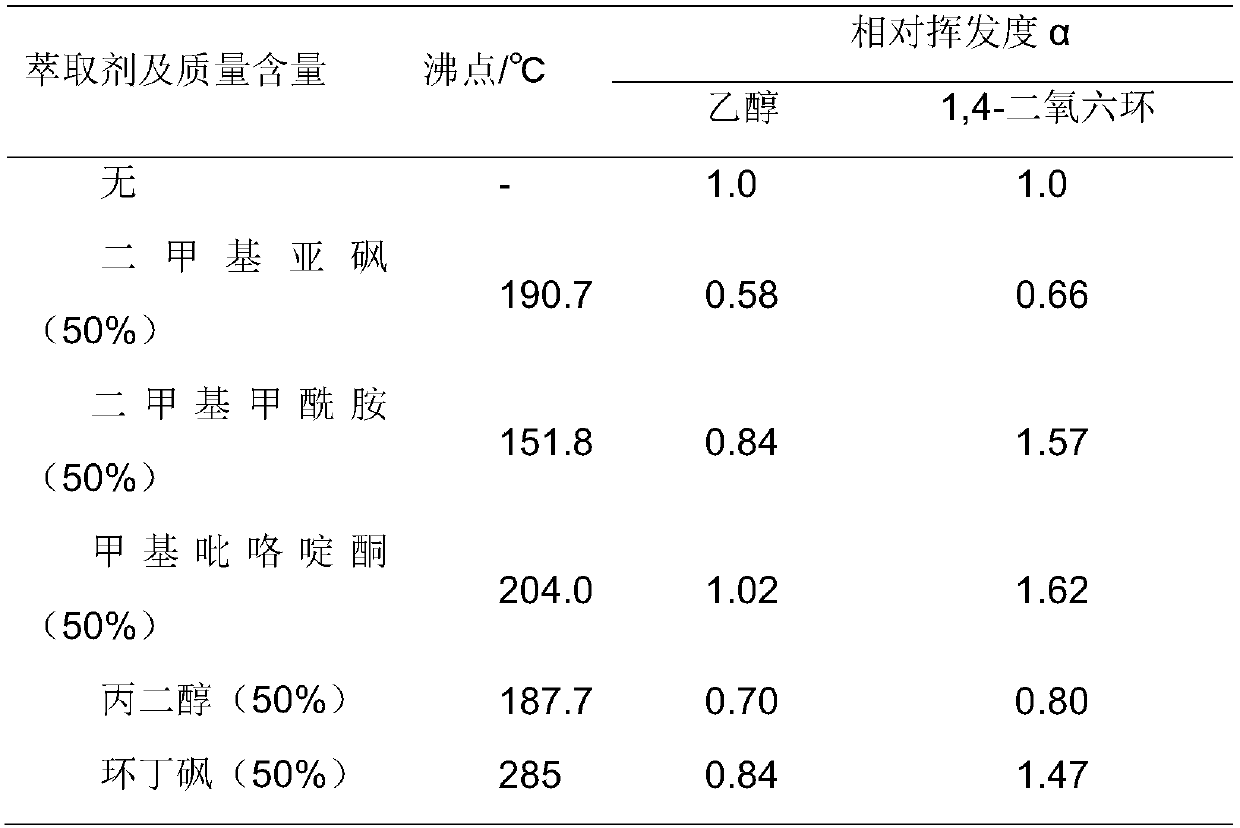

[0050] Dimethyl sulfoxide is used as the extractant, the flow rate of the extractant is 1500kg / h, the feed of the mixed solution is 1000kg / h, the feed composition of the mixed solution is ethanol 43%wt, 1,4-dioxane 5%wt, water 52%wt , the solvent ratio is 0.6, according to figure 1 process shown.

[0051] The theoretical plate number of the extraction column is 40, the operating pressure is 0.22MPaA, and the temperature at the top of the column is 100°C.

[0052] The theoretical plate number of the ethanol recovery tower is 70, the operating pressure is 0.20MPaA, the temperature at the top of the tower is 98°C, and the temperature at the bottom of the tower is 119°C.

[0053] The number of theoretical plates of the solvent recovery tower is 30, the operating pressure is 0.26MPaA, and the temperature at the top of the tower is 129°C.

[0054] The temperature of the vapor phase stream at the top of the solvent recovery tower is 10°C higher than the temperature of the 1,4-dioxa...

Embodiment 2

[0058] Dimethyl sulfoxide is used as the extractant, the flow rate of the extractant is 1500kg / h, the feed of the mixed solution is 1000kg / h, the feed composition of the mixed solution is ethanol 43%wt, 1,4-dioxane 5%wt, water 52%wt , the solvent ratio is 0.6, according to figure 1 process shown.

[0059] The theoretical plate number of the extraction column is 50, the operating pressure is 0.40MPaA, and the temperature at the top of the column is 118°C.

[0060] The theoretical plate number of the ethanol recovery tower is 70, the operating pressure is 0.33MPaA, the temperature at the top of the tower is 112°C, and the temperature at the bottom of the tower is 136°C.

[0061] The number of theoretical plates of the solvent recovery tower is 40, the operating pressure is 0.43MPaA, and the temperature at the top of the tower is 146°C.

[0062] The temperature of the vapor phase stream at the top of the solvent recovery tower is 10°C higher than the temperature of the 1,4-diox...

Embodiment 3

[0066] Dimethyl sulfoxide is used as the extractant, the flow rate of the extractant is 1500kg / h, the feed of the mixed solution is 1000kg / h, the feed composition of the mixed solution is ethanol 43%wt, 1,4-dioxane 5%wt, water 52%wt , the solvent ratio is 0.6, according to figure 1 process shown.

[0067] The theoretical plate number of the extraction column is 60, the operating pressure is 0.60MPaA, and the temperature at the top of the column is 118°C.

[0068] The theoretical plate number of the ethanol recovery tower is 70, the operating pressure is 0.53MPaA, the temperature at the top of the tower is 117°C, and the temperature at the bottom of the tower is 139°C.

[0069] The number of theoretical plates of the solvent recovery tower is 50, the operating pressure is 0.62MPaA, and the temperature at the top of the tower is 159°C.

[0070] The temperature of the vapor phase stream at the top of the solvent recovery tower is 20°C higher than the temperature of the 1,4-diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com