Coating material based on graphene nanometer container, and self-repairing coating, preparation method and applications thereof

A nano-container and graphene technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems that the coating cannot provide good shielding effect, the impact of the compactness of the coating film, and limit the wide range of applications, etc., to achieve Improve long-term protective properties, green raw materials, and excellent protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

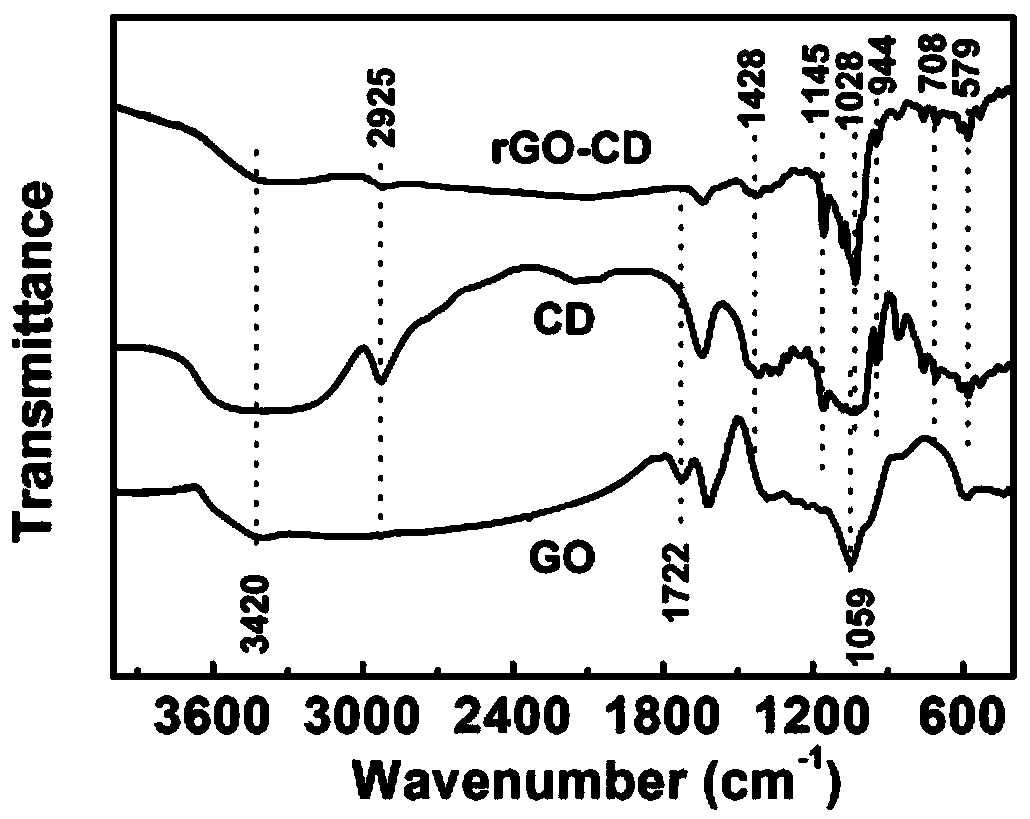

[0068] Embodiment 1 In this embodiment, a kind of preparation method based on the self-healing coating of graphene nano-container comprises:

[0069] (1) Disperse 1 molar part of graphene oxide (based on carboxyl content) and 1.2 molar parts of aminated cyclodextrin (based on amino content) in a certain amount of deionized water, ultrasonically disperse, and stir the cyclodextrin under magnetic stirring. The dextrin dispersion was slowly added dropwise into the graphene oxide dispersion. Place the above mixture in an oil bath at 85°C for 30 hours, centrifuge for 15 minutes (centrifugal speed is 4000-6000r / min), pour off the supernatant, and wash the lower sediment with deionized water and absolute ethanol. This process is repeated. 3 to 5 times to obtain a precipitate.

[0070] (2) Disperse 1.2 molar parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 1.2 molar parts of aminated cyclodextrin in a certain amount of deionized In water, slowly drop th...

Embodiment 2

[0077] Embodiment 2 In this embodiment, a kind of preparation method based on the self-healing coating of graphene nano container comprises:

[0078] (1) Disperse 1 molar part of graphene oxide (based on carboxyl content) and 1.2 molar parts of aminated cyclodextrin (based on amino content) in a certain amount of deionized water, ultrasonically disperse, and stir the cyclodextrin under magnetic stirring. The dextrin dispersion was slowly added dropwise into the graphene oxide dispersion. Place the above mixture in an oil bath at 85°C for 30 hours, centrifuge (4000-6000r / min) for 15 minutes, pour off the supernatant, and wash the lower sediment with deionized water and absolute ethanol. This process is repeated for 3 ~5 times, a precipitate was obtained.

[0079] (2) Disperse 1.2 molar parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 1.2 molar parts of aminated cyclodextrin in a certain amount of deionized In water, slowly drop the EDC dispersion...

Embodiment 3

[0086] Embodiment 3 In this embodiment, a kind of preparation method based on the self-healing coating of graphene nano container comprises:

[0087] (1) Disperse 1 molar part of graphene oxide (based on carboxyl content) and 1.1 molar parts of aminated cyclodextrin (based on amino content) in a certain amount of deionized water, ultrasonically disperse, and stir the cyclodextrin under magnetic stirring. The dextrin dispersion was slowly added dropwise into the graphene oxide dispersion. Place the above mixture in an oil bath at 85°C for 30 hours, centrifuge (4000-6000r / min) for 15 minutes, pour off the supernatant, and wash the lower sediment with deionized water and absolute ethanol. This process is repeated for 3 ~5 times, a precipitate was obtained.

[0088] (2) Disperse 1.1 molar parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 1.3 molar parts of aminated cyclodextrin in a certain amount of deionized In water, slowly drop the EDC dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com