Integrated multi-medium-catalysis waste gas treatment device and application method thereof

A waste gas treatment device and multi-media technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high cost, low efficiency of absorption method waste gas technology, unstable operation, etc., and achieve good results and alleviate VOCs. Pollution problem, the effect of solving the inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

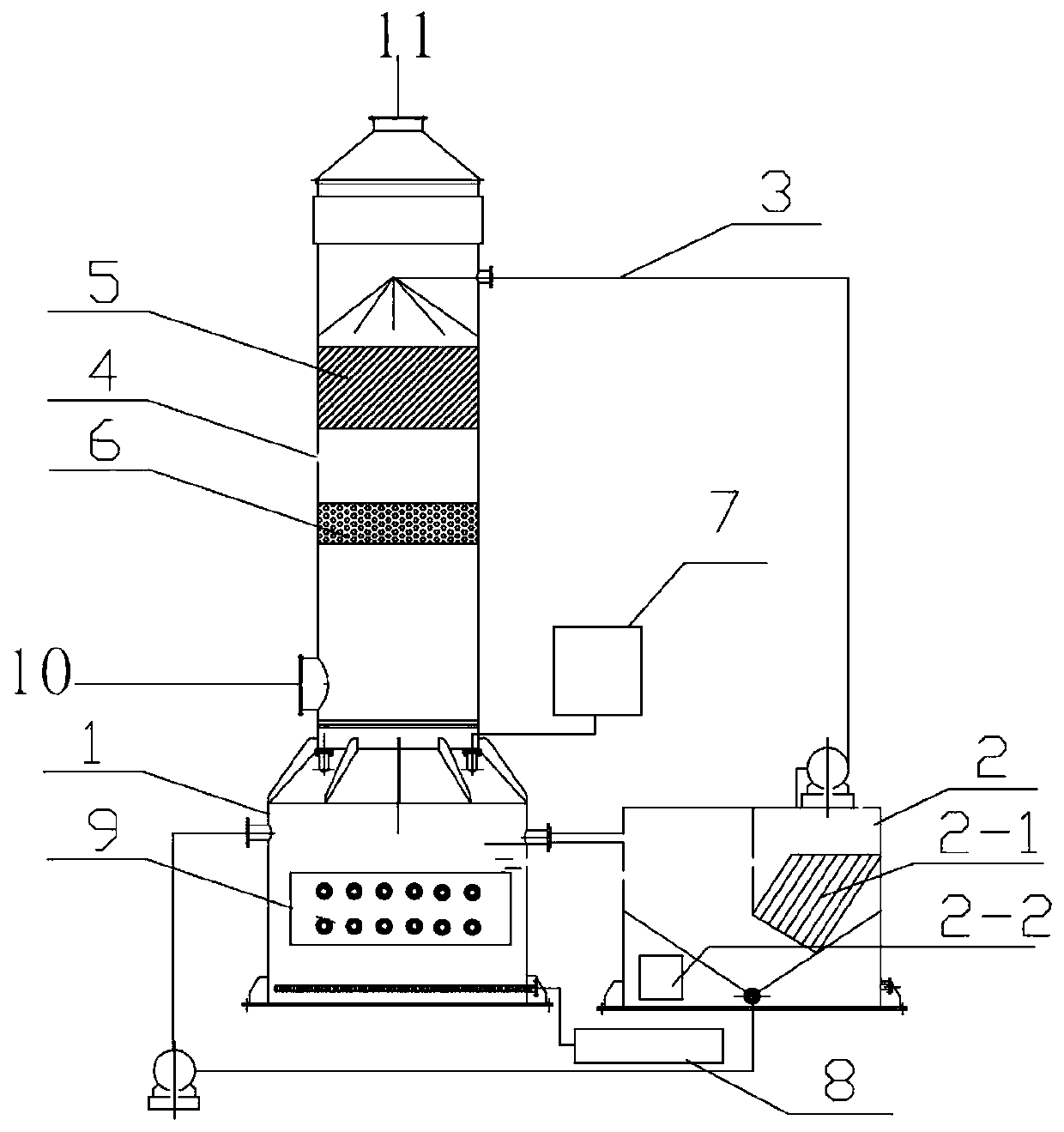

[0033] An integrated multi-media catalytic waste gas treatment device, consisting of an oxidation reaction tank 1, a photocatalyst recovery system 2, a circulating spray system 3, an absorption reactor 4, a dosing system 7, an ozone generation system 8, a UV catalytic system 9, an organic Exhaust gas inlet 10, organic waste gas outlet 11; wherein, the absorption reactor 4 includes a packing distribution layer 5 and an ozone catalytic oxidation bed 6, wherein the photocatalyst recovery system 2 includes a magnetic recovery section 2-1 and an inclined pipe section 2-2 .

[0034] The UV catalytic system 9 is arranged in the middle of the oxidation reaction tank 1 in a honeycomb socket type. The ozone generated by the ozone generation system 8 enters the oxidation reaction tank 1 through the pipeline, and enters the oxidation reaction tank 1 by means of submerged aeration. On the one hand, it plays an oxidation role. The bubbles generated on the one hand make the photocatalyst in ...

Embodiment 2

[0042] An integrated multi-media catalytic waste gas treatment device, consisting of an oxidation reaction tank 1, a photocatalyst recovery system 2, a circulating spray system 3, an absorption reactor 4, a dosing system 7, an ozone generation system 8, a UV catalytic system 9, an organic Exhaust gas inlet 10, organic waste gas outlet 11; wherein, the absorption reactor 4 includes a packing distribution layer 5 and an ozone catalytic oxidation bed 6, wherein the photocatalyst recovery system 2 includes a magnetic recovery section 2-1 and an inclined pipe section 2-2 .

[0043]The UV catalytic system 9 is arranged in the middle of the oxidation reaction tank 1 in a honeycomb socket type. The ozone generated by the ozone generation system 8 enters the oxidation reaction tank 1 through the pipeline, and enters the oxidation reaction tank 1 by means of submerged aeration. On the one hand, it plays an oxidation role. The bubbles generated on the one hand make the photocatalyst in t...

Embodiment 3

[0051] An integrated multi-media catalytic waste gas treatment device, consisting of an oxidation reaction tank 1, a photocatalyst recovery system 2, a circulating spray system 3, an absorption reactor 4, a dosing system 7, an ozone generation system 8, a UV catalytic system 9, an organic Exhaust gas inlet 10, organic waste gas outlet 11; wherein, the absorption reactor 4 includes a packing distribution layer 5 and an ozone catalytic oxidation bed 6, wherein the photocatalyst recovery system 2 includes a magnetic recovery section 2-1 and an inclined pipe section 2-2 .

[0052] The UV catalytic system 9 is arranged in the middle of the oxidation reaction tank 1 in a honeycomb socket type. The ozone generated by the ozone generation system 8 enters the oxidation reaction tank 1 through the pipeline, and enters the oxidation reaction tank 1 by means of submerged aeration. On the one hand, it plays an oxidation role. The bubbles generated on the one hand make the photocatalyst in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com