Iron-cobalt bimetal-organic framework material based on 2, 5-dihydroxy terephthalic acid ligand as well as preparation method and application of iron-cobalt bimetal-organic framework material

A technology of hydroxyterephthalic acid and organic framework, which is applied in the field of iron-cobalt bimetallic-organic framework materials and its preparation, can solve the problems of secondary pollution, increase of processing costs, cobalt ions cannot be recycled and utilized in the environment, and achieve high utilization rate High, short reaction time, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

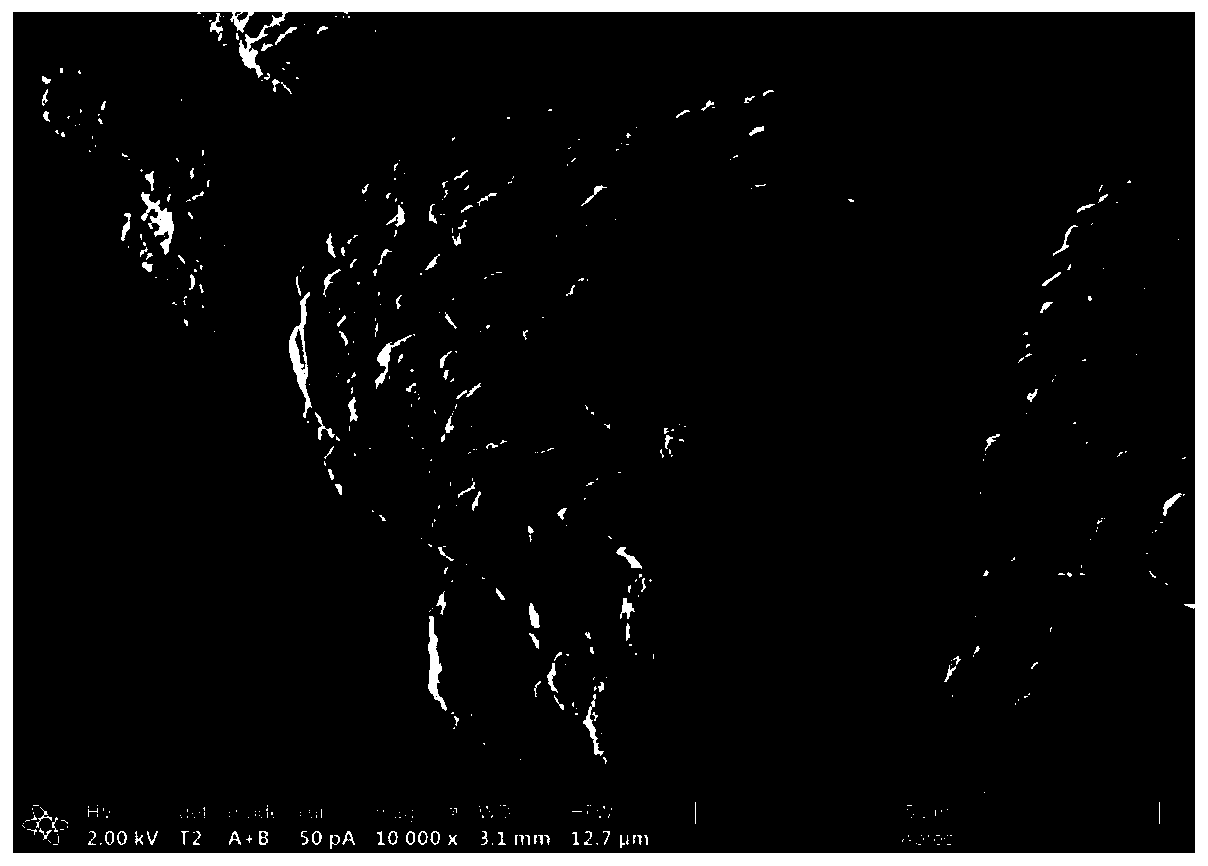

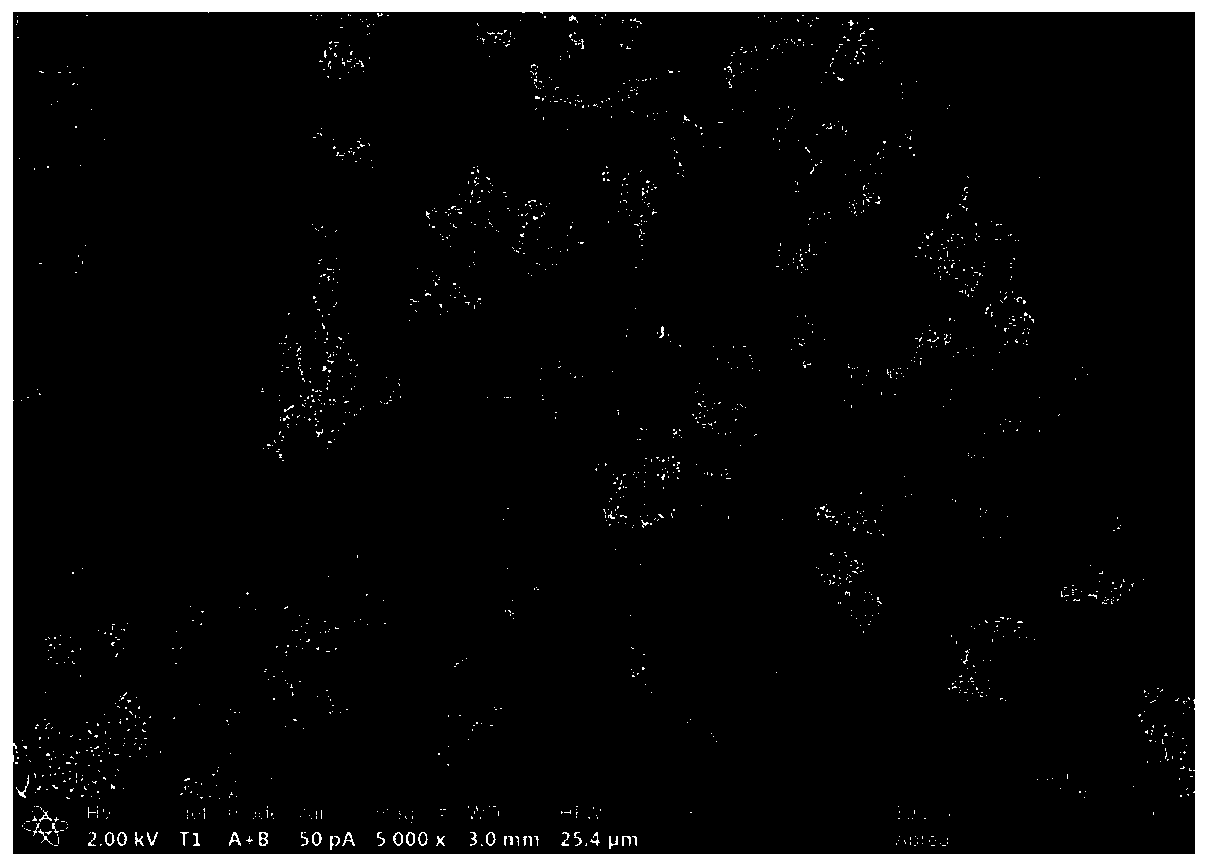

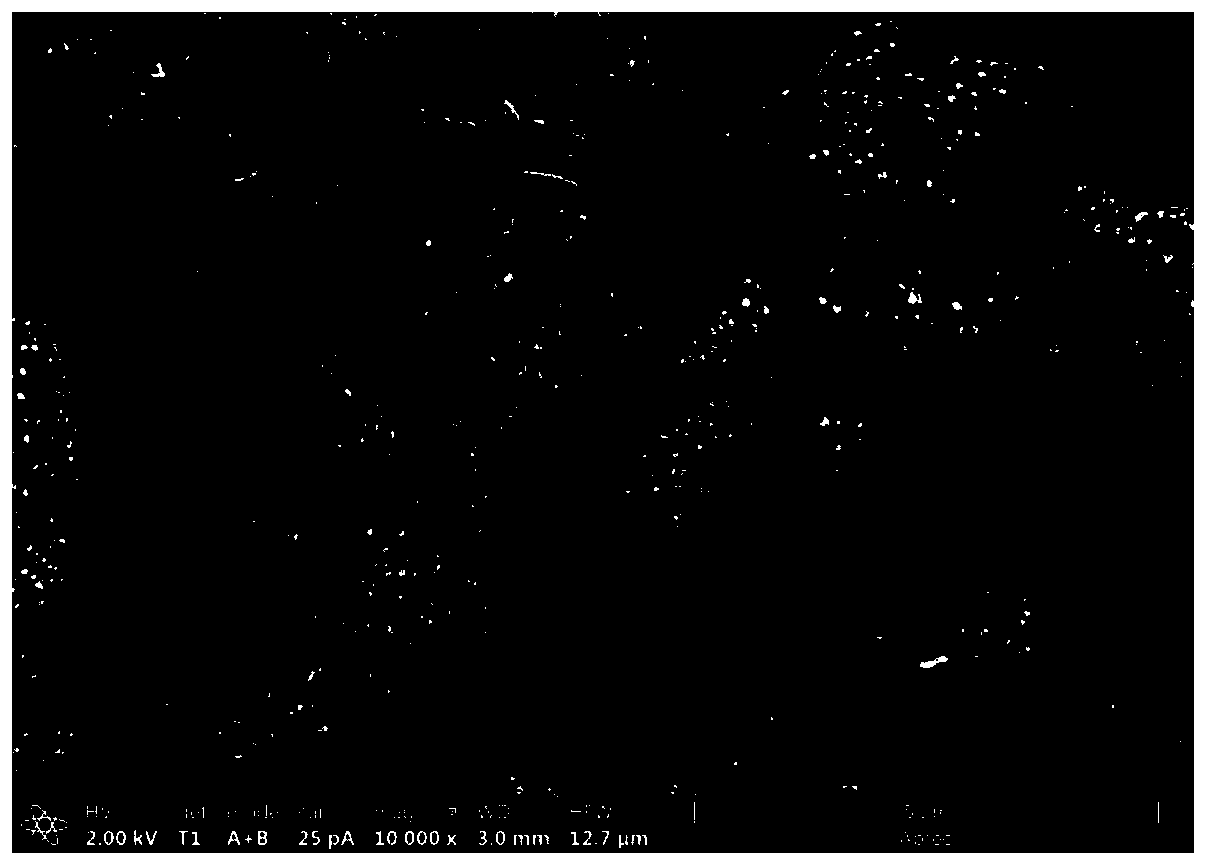

Image

Examples

Embodiment 1

[0035] Preparation of Iron-Cobalt Bimetallic-Organic Framework Materials

[0036] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.596g (3mM) FeCl 2 4H 2 O and 0.498g (3mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60mL N,N-dimethylformamide (DMF) and ethanol mixture (DMF:ethanol=1:1), Stir the above mixed solution until it is completely dissolved to obtain a precursor solution;

[0037] (2) Iron-cobalt bimetallic-organic framework based on 2,5-dihydroxyterephthalic acid ligand: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave , put the reaction kettle in a programmed oven, solvothermal reaction at 150°C for 24h; cool down, cool down to room temperature naturally, filter with a vacuum pump and repeat with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water Wash to obtain a brown precipitate; put the precipitate in a vacuum oven at 100°C and dry for 12 hours...

Embodiment 2

[0040] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.596g (3mM) FeCl 2 4H 2 O and 0.498g (3mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60mL N,N-dimethylformamide (DMF) and ethanol mixture (DMF:ethanol=1:1), Stir the above mixed solution until it is completely dissolved to obtain a precursor solution;

[0041] (2) Iron-cobalt bimetallic-organic framework based on 2,5-dihydroxyterephthalic acid ligand: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave , put the reaction kettle in a programmed oven, solvothermal reaction at 110°C for 24 hours; cool down, naturally cool down to room temperature, filter with a vacuum pump and repeat with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water Wash to obtain a brown precipitate; put the precipitate in a vacuum oven at 100°C and dry for 12 hours to obtain a black solid powder, which is an iron-cobalt bimetallic-org...

Embodiment 3

[0044] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.596g (3mM) FeCl 2 4H 2 O and 0.498g (3mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60mL N,N-dimethylformamide (DMF) and ethanol mixture (DMF:ethanol=1:1), Stir the above mixed solution until it is completely dissolved to obtain a precursor solution;

[0045] (2) Iron-cobalt bimetallic-organic framework based on 2,5-dihydroxyterephthalic acid ligand: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave , put the reaction kettle in a programmed oven, solvothermal reaction at 170°C for 24 hours; cool down, cool down to room temperature naturally, and filter with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water repeatedly Wash to obtain a brown precipitate; put the precipitate in a vacuum oven at 100°C and dry for 12 hours to obtain a black solid powder, which is an iron-cobalt bimetallic-organic framework ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com