Y molecular sieve for synthesizing dimethyl carbonate through carbonylation of methyl nitrite, and preparation method thereof

A technology of methyl nitrite and dimethyl carbonate is applied in the preparation of carbonate/haloformate, the preparation of organic compounds, molecular sieve catalysts, etc., to achieve the effect of improving space-time yield and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Add 25ml of water to a 100ml beaker, and then add 1.6g of NaAlO 2 and 1.6g NaOH. Also add 25ml water to another 100ml beaker, add 11.1gNaSiO 3 ·5H 2 O. After the water in the two beakers is completely dissolved, mix together and stir for 10 minutes, and age at room temperature for 24 hours to make a directing agent;

[0026] 2. Add 30g NaSiO to a 250ml beaker 3 ·5H 2 O and 100ml water, stir to make it dissolve completely to obtain the silicon source solution; take another 250ml beaker and add 5.5g NaAlO 2 , 2.5gNaOH and 100ml water, stir until completely dissolved, add to the silicon source solution and mix evenly; add 1.2gNaOH in a water bath at 50°C while stirring 4 TiO 4 And the directing agent of 5g step 1; Continue to stir 30min, make the gel reaction mixture.

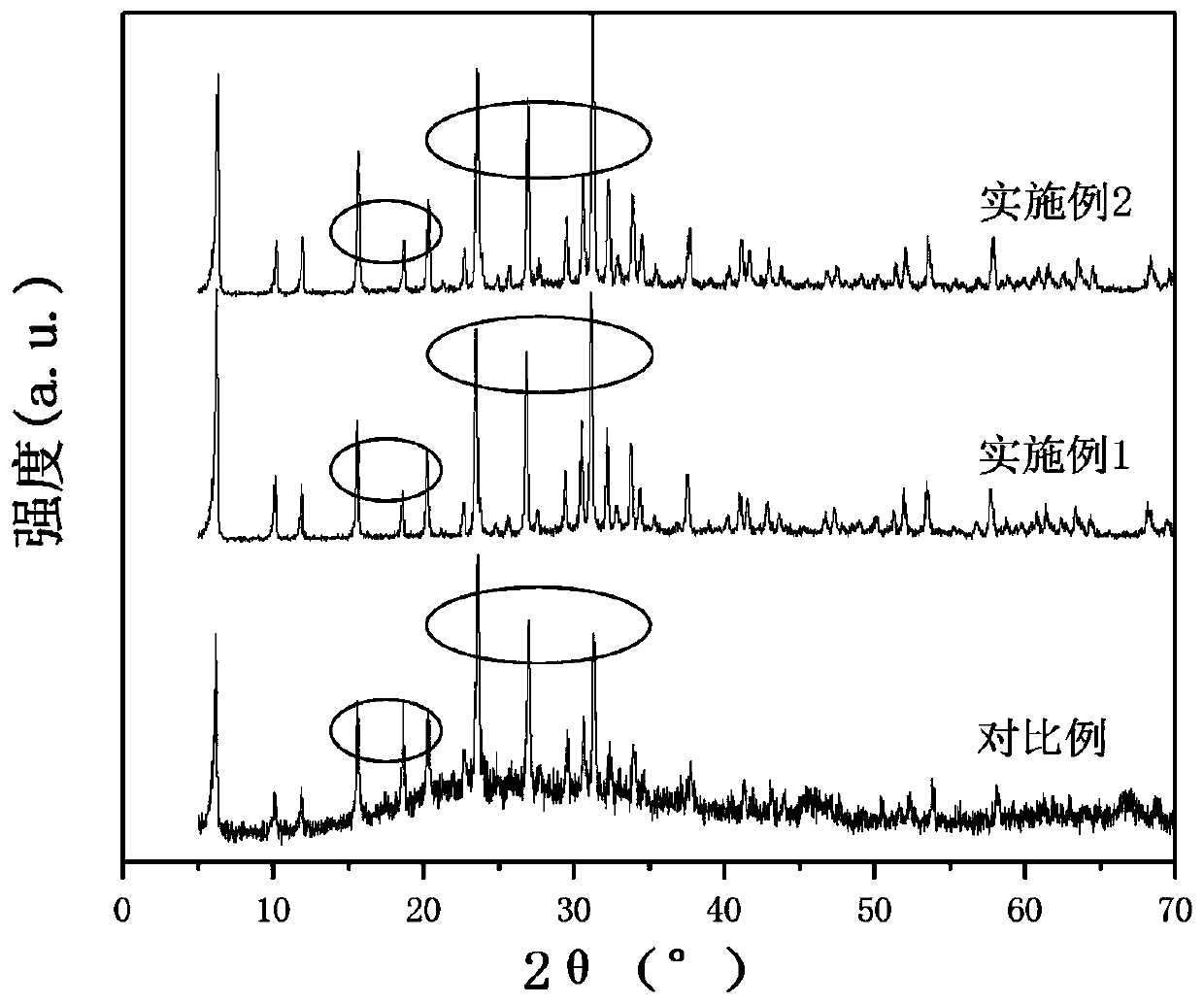

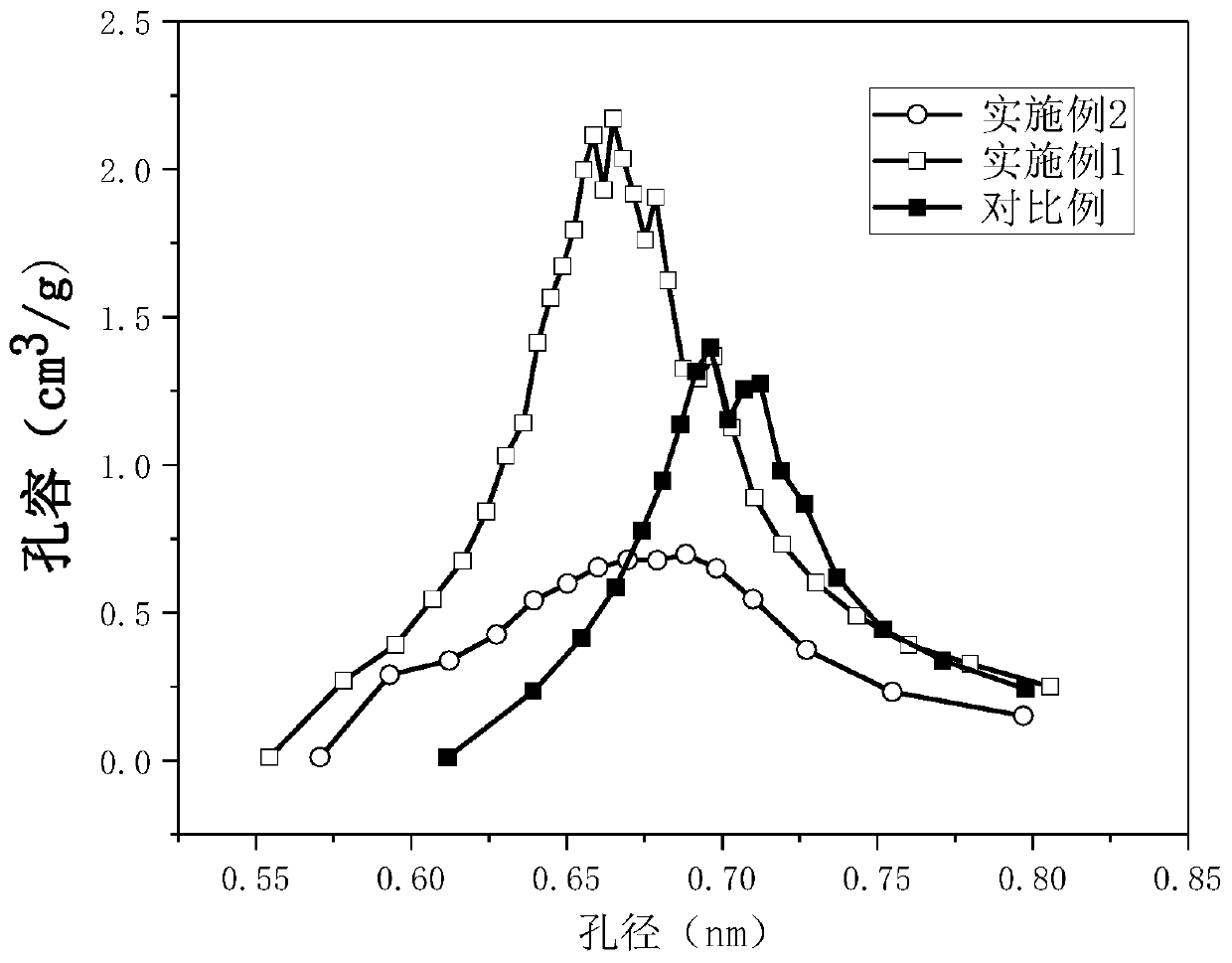

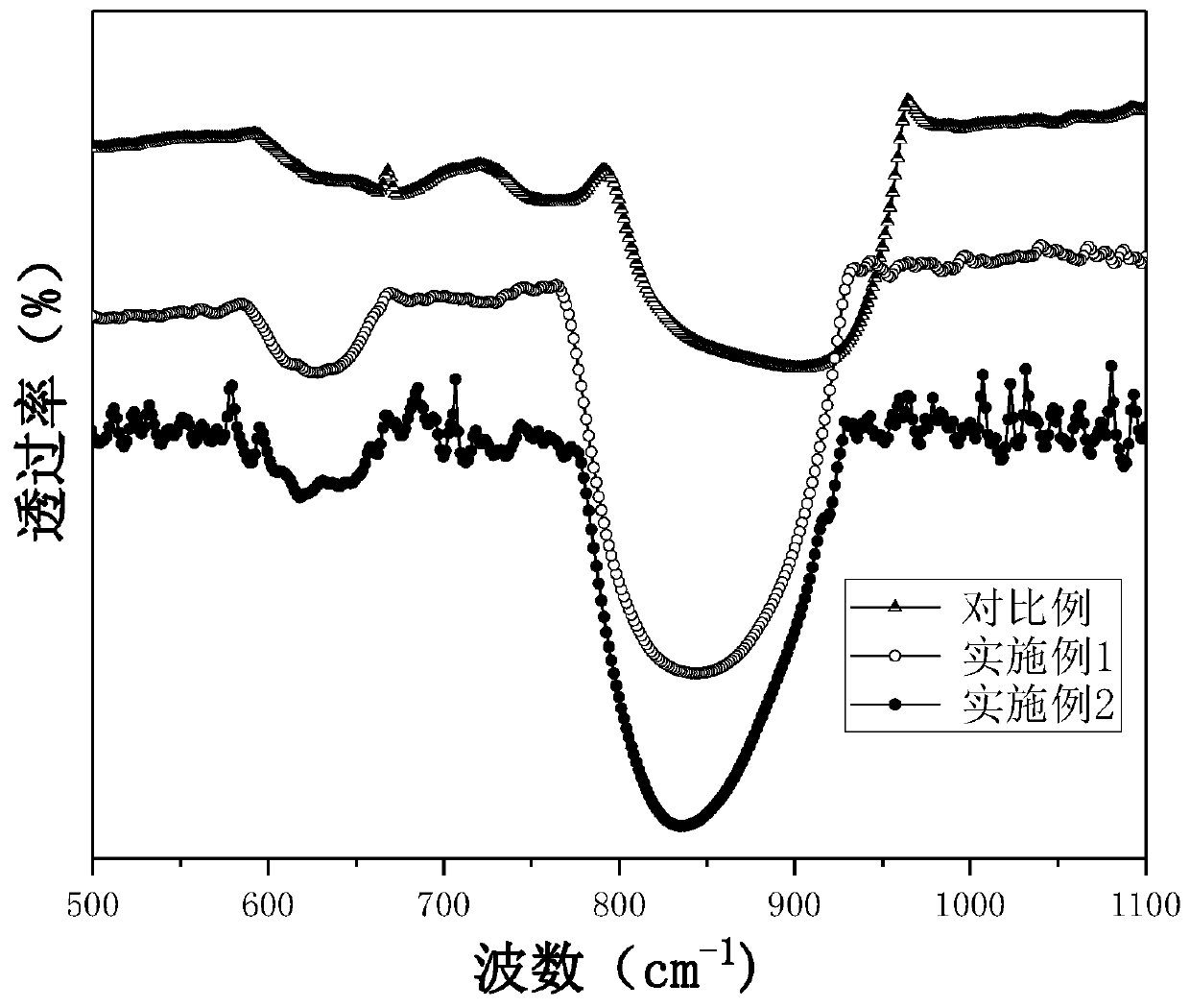

[0027] Put the above-mentioned gel reaction mixture into a reaction kettle, place it in a microwave device for treatment for 10min; Roasting to obtain Y molecular sieve.

Embodiment 2

[0029] 1. Add 25ml of water to a 100ml beaker, and then add 1.6g of NaAlO 2 and 1.6g NaOH. Also add 25ml water to another 100ml beaker, add 11.1gNaSiO 3 ·5H 2 O. After the water in the two beakers is completely dissolved, mix together and stir for 10 minutes, and age at room temperature for 24 hours to make a directing agent;

[0030] 2. Add 30g NaSiO to a 250ml beaker 3 ·5H 2 O and 100ml water, stir to make it completely dissolve to obtain silicon source solution; take another 250ml beaker and add 5.5g NaAlO 2, 2.5gNaOH and 100ml water, stir until completely dissolved, add to the silicon source solution and mix evenly; add 1.5gNaOH in a water bath at 50°C while stirring 3 PO 4 And 5g of the directing agent of the above-mentioned step 1, continue stirring for 30min to prepare a gel reaction mixture.

[0031] Put the above-mentioned gel reaction mixture into a reaction kettle, place it in a microwave device for treatment for 10 minutes, then transfer it to a polytetrafl...

Embodiment 3

[0033] 1. Add 25ml of water to a 100ml beaker, and then add 1.6g of NaAlO 2 and 1.6g NaOH. Also add 25ml water to another 100ml beaker, add 11.1gNaSiO 3 ·5H 2 O. After the water in the two beakers is completely dissolved, mix together and stir for 10 minutes, and age in a water bath at 50°C for 24 hours to make a directing agent;

[0034] 2. Add 45g NaSiO to a 250ml beaker 3 ·5H 2 O and 100ml water, stirred to make it completely dissolved to obtain the silicon source solution; another 250ml beaker was added with 3.8g NaAlO 2 , 5gNaOH and 100ml water, stir until completely dissolved, add to the silicon source solution and mix evenly; add 1.2gNaOH in a water bath at 50°C while stirring 4 TiO 4 And 8g of the directing agent of the above-mentioned step 1, continue stirring for 30min to prepare a gel reaction mixture.

[0035] Put the above-mentioned gel reaction mixture into a reaction kettle, place it in a microwave device for treatment for 15 minutes, then transfer it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com