LaBiO3 film, and LaBiO3 ceramic target material and preparation method thereof

A technology of ceramic target material and adhesive, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., and can solve the problems such as the decline of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

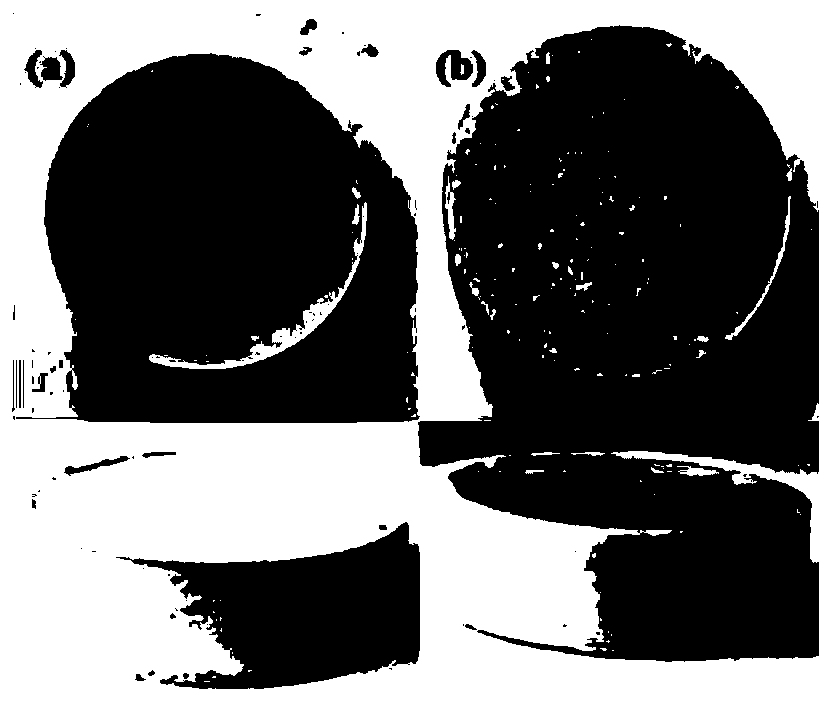

Image

Examples

preparation example Construction

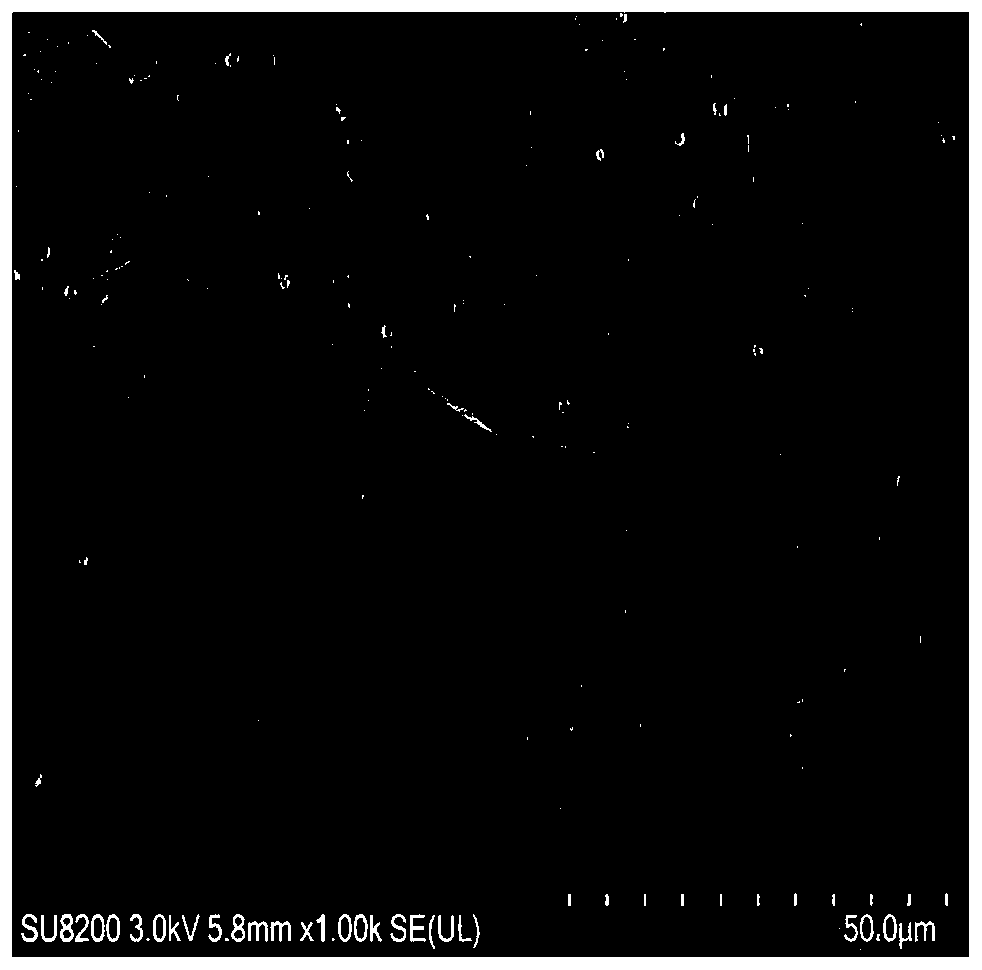

[0032] Given the preparation of LaBiO 3 The target density, purity and uniformity of the thin film, this application provides a brand new LaBiO 3 Ceramic target material, this kind of oxide ceramic target material is synthesized for the first time, and has high density, purity and uniformity, and the surface quality of the oxide film grown from this target material is high. Specifically, the embodiment of the present invention discloses a LaBiO 3 A method for preparing a ceramic target, comprising the following steps:

[0033] A) La 2 o 3 and Bi 2 o 3 After mixing according to the stoichiometric ratio of 1:1.1, ball milling is carried out, and the initial mixture is obtained after classification;

[0034] B) pre-sintering the initial mixture after being placed on an alumina pad to obtain an initial sintered powder;

[0035] C) mixing the initial sintered powder with a binder and then drying to make a green body to obtain a ceramic green body;

[0036] D) sintering the ...

Embodiment 1

[0046] Baking material: Weigh 15gLa respectively 2 o 3 (analytically pure, AR) and 15gBi 2 o 3 (analytical pure, AR) was put into a crucible, covered with a crucible lid, and baked in an oven for 4 hours at a temperature of 100°C;

[0047] Ingredients: Weigh 7.7725g La with an analytical balance 2 o 3 and 12.2275g Bi 2 o 3 , La 2 o 3 and Bi 2 o 3 The stoichiometric ratio is 1:1.1, because Bi is volatile at high temperature;

[0048] Ball milling: Put the powder into a nylon tank with zirconia balls as the balls for mixing, mill in the ball mill for 2 days, put the milled powder into a 100-mesh porous sieve for classification, and put the uniform powder into the oven save;

[0049] Pre-sintering: Put the uniformly mixed powder on the alumina gasket, and put it in a high-temperature furnace for pre-sintering, raise the temperature from room temperature to 500°C at 5°C / min, then raise the temperature to 880°C at 2°C / min, and keep it for 1h , naturally cooled to room ...

Embodiment 2

[0058] Baking material: Weigh 15gLa respectively 2 o 3 (analytically pure, AR) and 15gBi 2 o 3 (analytical pure, AR) was put into a crucible, covered with a crucible lid, and baked in an oven for 4 hours at a temperature of 100°C;

[0059] Ingredients: Weigh 7.7725g La with an analytical balance 2 o 3 and 12.2275g Bi 2 o 3 , La 2 o 3 and Bi 2 o 3 The stoichiometric ratio is 1:1.1, because Bi is volatile at high temperature;

[0060] Ball milling: Put the powder into a nylon tank with zirconia balls as the balls for mixing, mill in the ball mill for 2 days, put the milled powder into a 100-mesh porous sieve for classification, and put the uniform powder into the oven save;

[0061] Pre-sintering: Put the uniformly mixed powder on the alumina gasket, and put it in a high-temperature furnace for pre-sintering, raise the temperature from room temperature to 500°C at 5°C / min, then raise the temperature to 880°C at 2°C / min, and keep it for 1h , naturally cooled to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com