Preparation method of self-supporting Co-MOF/TM nanosheet array, electrochemical biosensor and application

A nanosheet array and biosensor technology, applied in the field of new nanomaterials, can solve the problems of low conductivity and catalytic activity, and achieve the effects of fast electron transfer rate, high selectivity and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

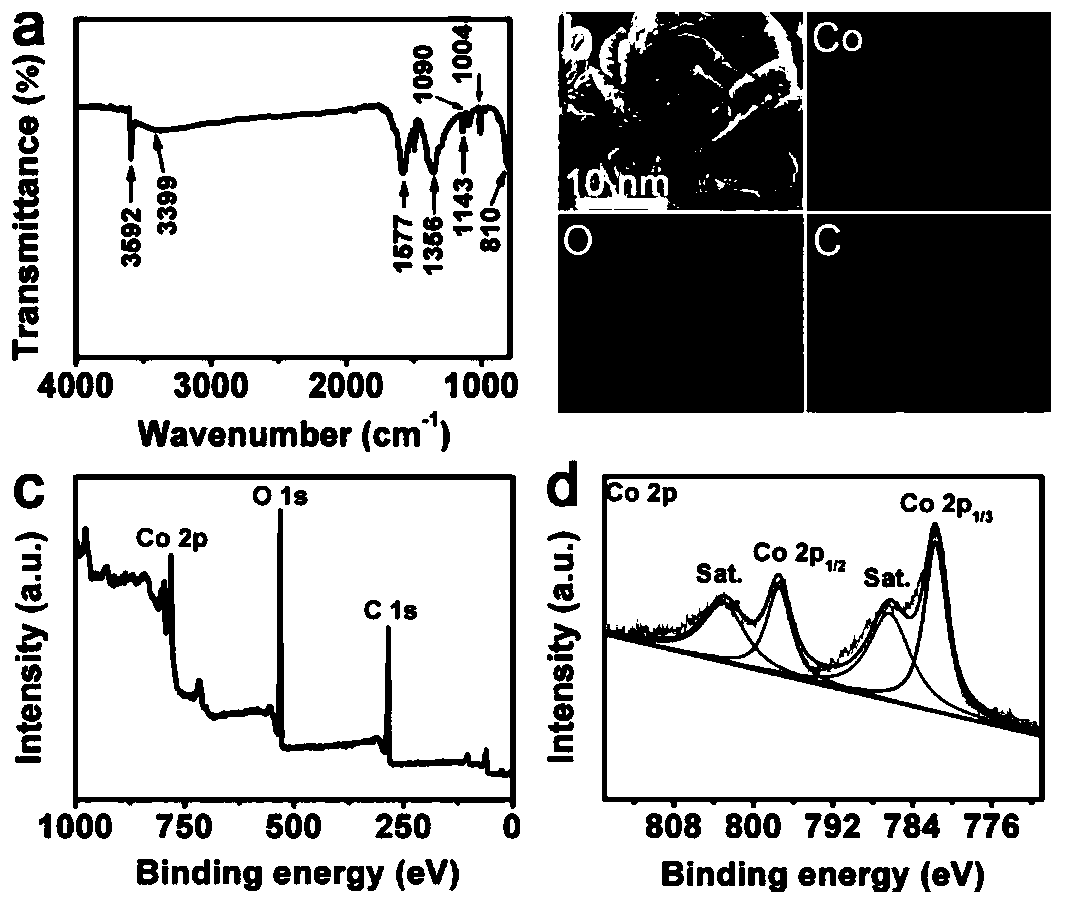

Embodiment 1

[0030] 0.238 g CoCl 2 • 6 H 2 O and 0.166 g TPA were dissolved in 33 ml DMF and stirred for 10 min. Then add 2.5 ml ethanol and 2.5 ml deionized water and stir for 25 minutes. The above mixture was transferred to a 50 ml autoclave and a clean titanium mesh (TM) was placed in it. The reaction was carried out at 125°C for 12 hours. Finally, the obtained sample was naturally cooled, washed three times with deionized water and ethanol, and dried in air at 60 °C for 6 h to obtain Co-MOF / TM.

Embodiment 2

[0032] 0.25 g CoCl 2 • 6 H 2 O and 0.18 g TPA were dissolved in 40 ml DMF and stirred for 10 min. Add 3 ml of ethanol and 3 ml of deionized water and stir for 30 minutes. The above mixture was transferred to a 50 ml autoclave and a clean titanium mesh (TM) was placed in it. The reaction was carried out at 125°C for 12 hours. Finally, the obtained sample was naturally cooled, washed three times with deionized water and ethanol, and dried in air at 60 °C for 6 h to obtain the Co-MOF / TM

Embodiment 3

[0034] 0.20 g CoCl 2 • 6 H 2 O and 0.15 g TPA were dissolved in 30 ml DMF and stirred for 10 min. Add 2 ml of ethanol and 2 ml of deionized water and stir for 20 minutes. The above mixture was transferred to a 50 ml autoclave and a clean titanium mesh (TM) was placed in it. The reaction was carried out at 125°C for 12 hours. Finally, the obtained sample was naturally cooled, washed three times with deionized water and ethanol, and dried in air at 60 °C for 6 h to obtain the Co-MOF / TM

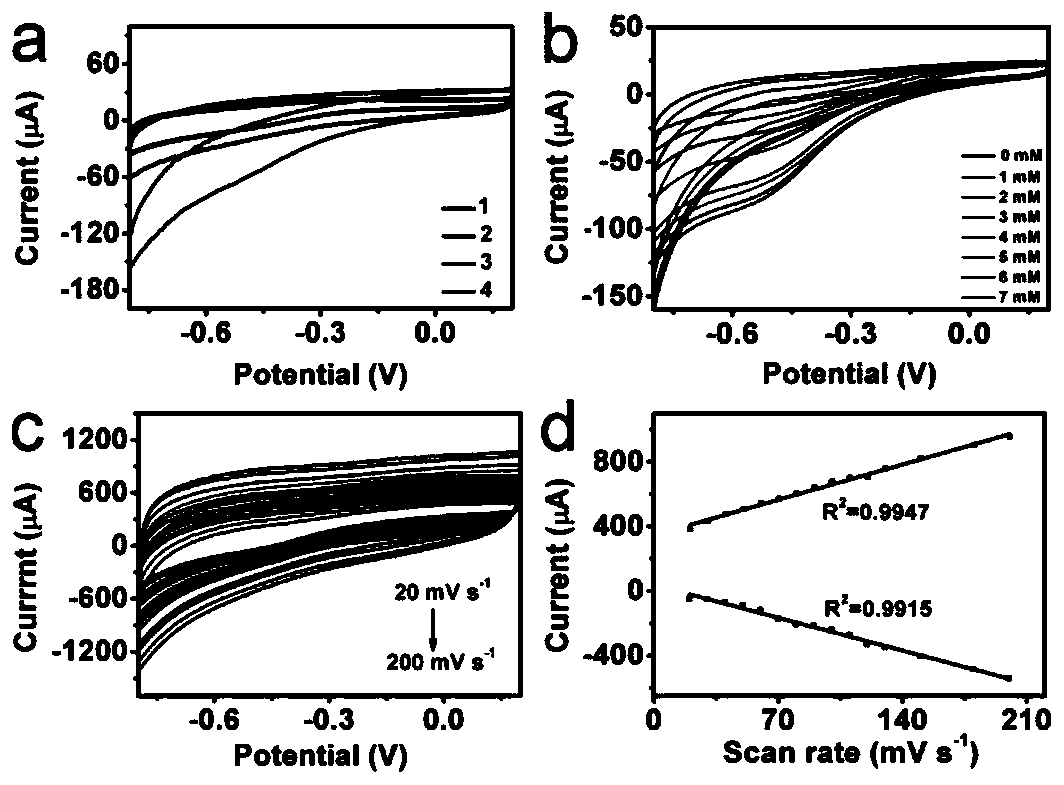

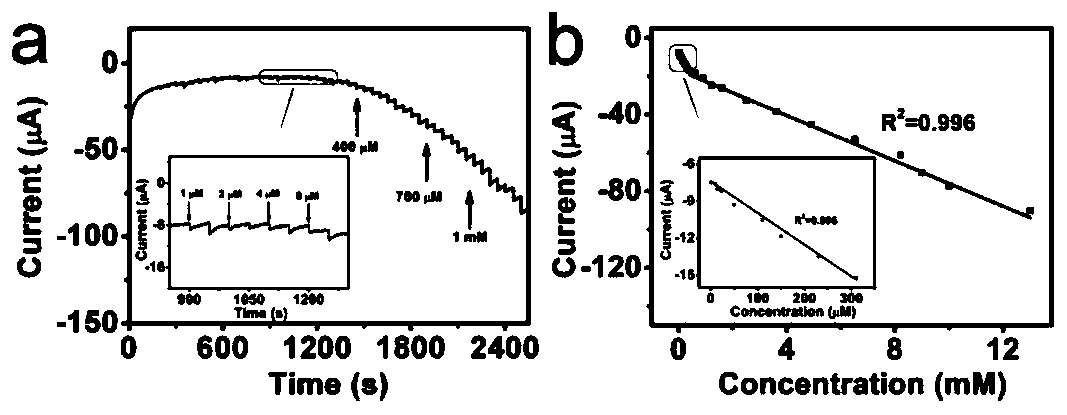

[0035] electrochemical biosensor

[0036] The electrochemical biosensor of the present invention comprises a working electrode connected to an electrochemical workstation, a reference electrode (Ag|AgCl|Cl - ), the counter electrode (graphite electrode), the working electrode is a titanium mesh (TM), and the working electrode is a titanium mesh (TM) decorated with the Co-MOF / TM nanosheet array prepared in the example. Ultrasonic cleaning in pure water for 15 min, the area of the TM electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com