A method for rapid detection of tyrosine concentration

A tyrosine and concentration technology, which is applied to measurement devices, instruments, electrochemical variables of materials, etc., can solve the problems of insensitive detection of mixed samples, inability to meet rapid detection, complicated and time-consuming pretreatment, and achieve good surface and interface characteristics. and electrochemical, eliminate electronic interference factors, the effect of fast electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for rapidly detecting tyrosine concentration, comprising the following steps:

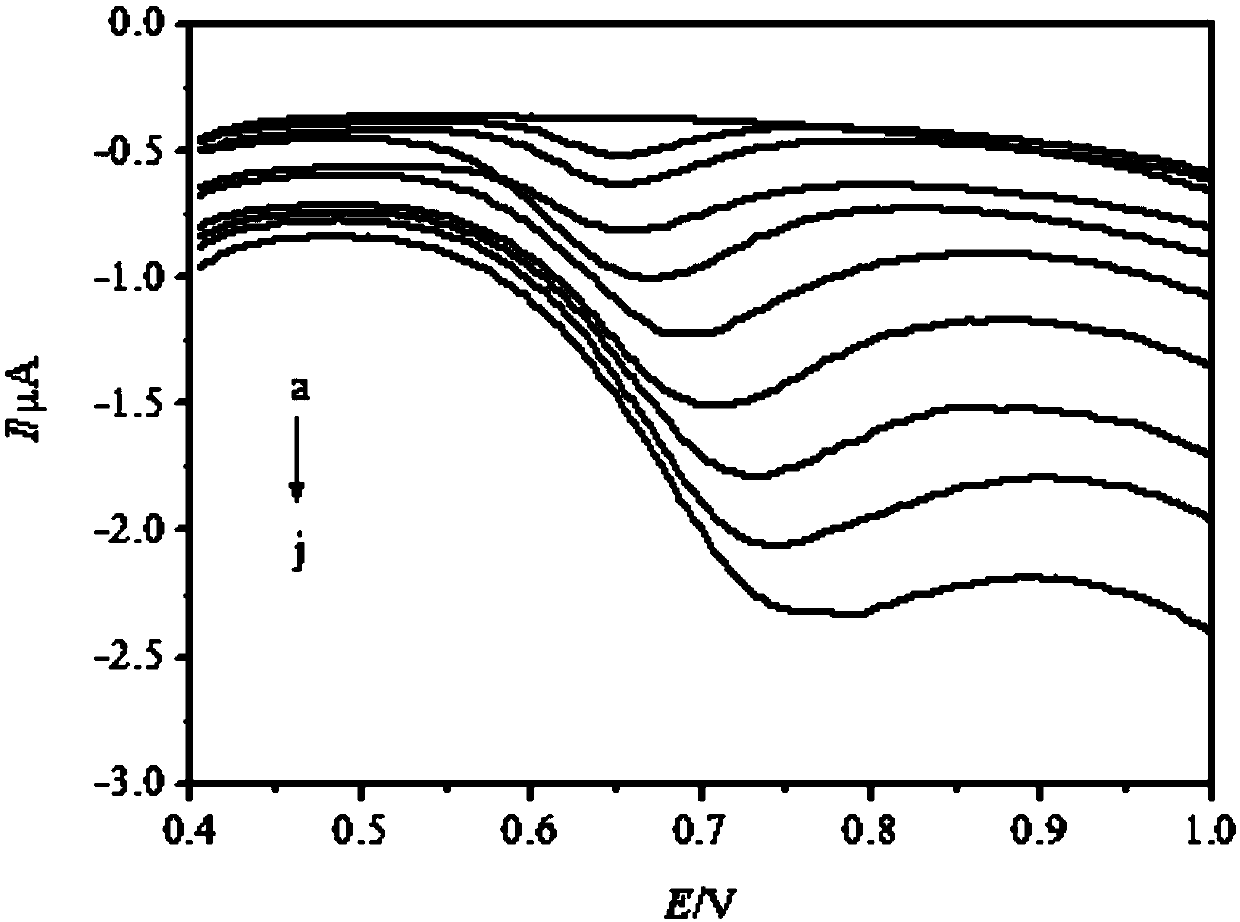

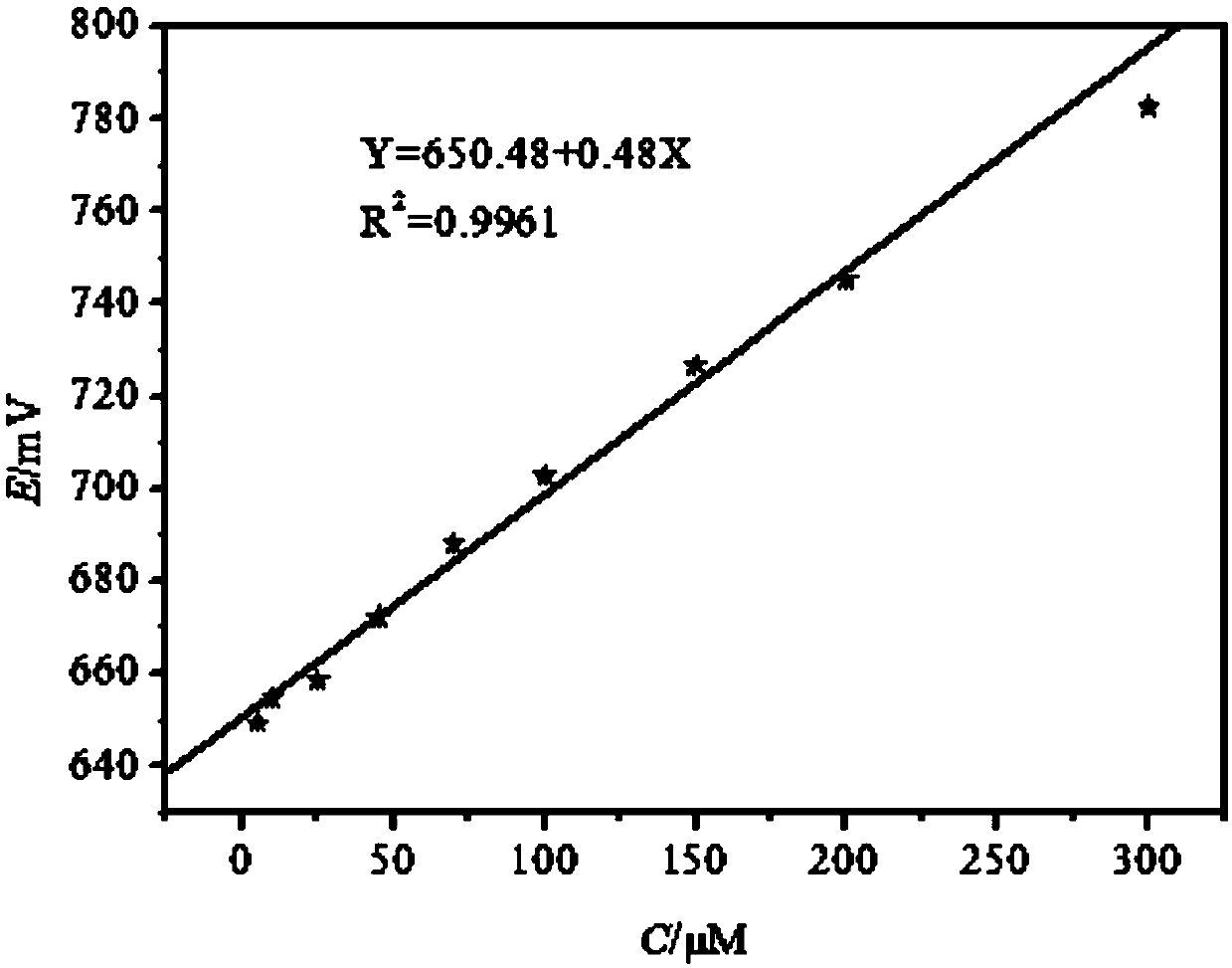

[0029] Step 1. Prepare multiple PBS buffer solutions containing different concentrations of tyrosine. The pH of the PBS buffer solution is 7.4, the concentration is 0.1mol / L, and the tyrosine concentration is 5.0×10 -6 mol / L, 1×10 -5 mol / L, 2.5×10 - 5 mol / L, 4.5×10 -5 mol / L, 7×10 -5 mol / L, 1×10 -4 mol / L, 1.5×10 -4 mol / L, 2×10 -4 mol / L, 3×10 -4 mol / L. Use the glassy carbon electrode as the working electrode to build a three-electrode system, set the initial potential to 0.4V, the end potential to 1.0V, and then set the following pulse parameters: the potential increment is 0.004V, the square wave frequency is 50Hz, and the square wave amplitude is 0.05 V, the waiting time is 2s. Using differential pulse voltammetry, measure and record the differential pulse voltammetry curves of multiple PBS buffer solutions containing different concentrations of tyrosine, and record the pe...

Embodiment 2

[0035] A method for rapid detection of tyrosine concentration, the assay steps are the same as in Example 1, wherein,

[0036] The glassy carbon electrode has been polished, specifically as follows: soak the glassy carbon electrode in an aqueous solution of purple sweet potato powder for 20 minutes, take out the glassy carbon electrode and soak it in a carbon tetrachloride solution of soybean lecithin for 20 minutes, and then use 95% of the mass fraction in turn. Ultrasonic cleaning with ethanol aqueous solution and double distilled water for 5 minutes respectively, and then grinding with alumina powder with a particle size of 0.3 μm and 0.05 μm in sequence, then ultrasonic cleaning with 95% ethanol aqueous solution and double distilled water for 5 minutes, and finally using nitrogen gas Just blow dry;

[0037] Wherein, the preparation of the aqueous solution of purple sweet potato powder is as follows: purple sweet potato powder and deionized water are mixed in a mass volume ...

Embodiment 3

[0045] A method for rapid detection of tyrosine concentration, the assay steps are the same as in Example 1, wherein,

[0046] The glassy carbon electrode is polished, specifically: soak the glassy carbon electrode in an aqueous solution of purple sweet potato powder for 30 minutes, take out the glassy carbon electrode and soak it in a carbon tetrachloride solution of soybean lecithin for 30 minutes, and then use 95% of the mass fraction in turn. Ultrasonic cleaning with ethanol aqueous solution and double distilled water for 10 minutes respectively, and then grinding with alumina powder with a particle size of 0.3 μm and 0.05 μm in sequence, then ultrasonic cleaning with 95% ethanol aqueous solution and double distilled water for 10 minutes, and finally using nitrogen gas Just blow dry;

[0047] Wherein, the preparation of the aqueous solution of purple sweet potato powder is as follows: purple sweet potato powder and deionized water are mixed at a mass volume ratio of 1g:20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com