Graphene-containing aircraft tire sealing layer rubber material and preparation method thereof

An aviation tire and graphene technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems affecting the use of aviation tires, the gap in pressure holding performance, and the poor pressure holding ability, so as to facilitate manufacturing and implementation, Good air tightness, the effect of improving air tightness and pressure holding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned graphene-containing aircraft tire sealing layer compound adopts a two-stage mixing method of an internal mixer, and comprises the following steps:

[0035] In the first step, the masterbatch is obtained by mixing halogenated butyl rubber, carbon black, graphene, flake mineral materials and other materials;

[0036] In the second step, put the masterbatch back into the internal mixer, add vulcanizing agent and accelerator at a lower temperature and mix to obtain the final rubber mix.

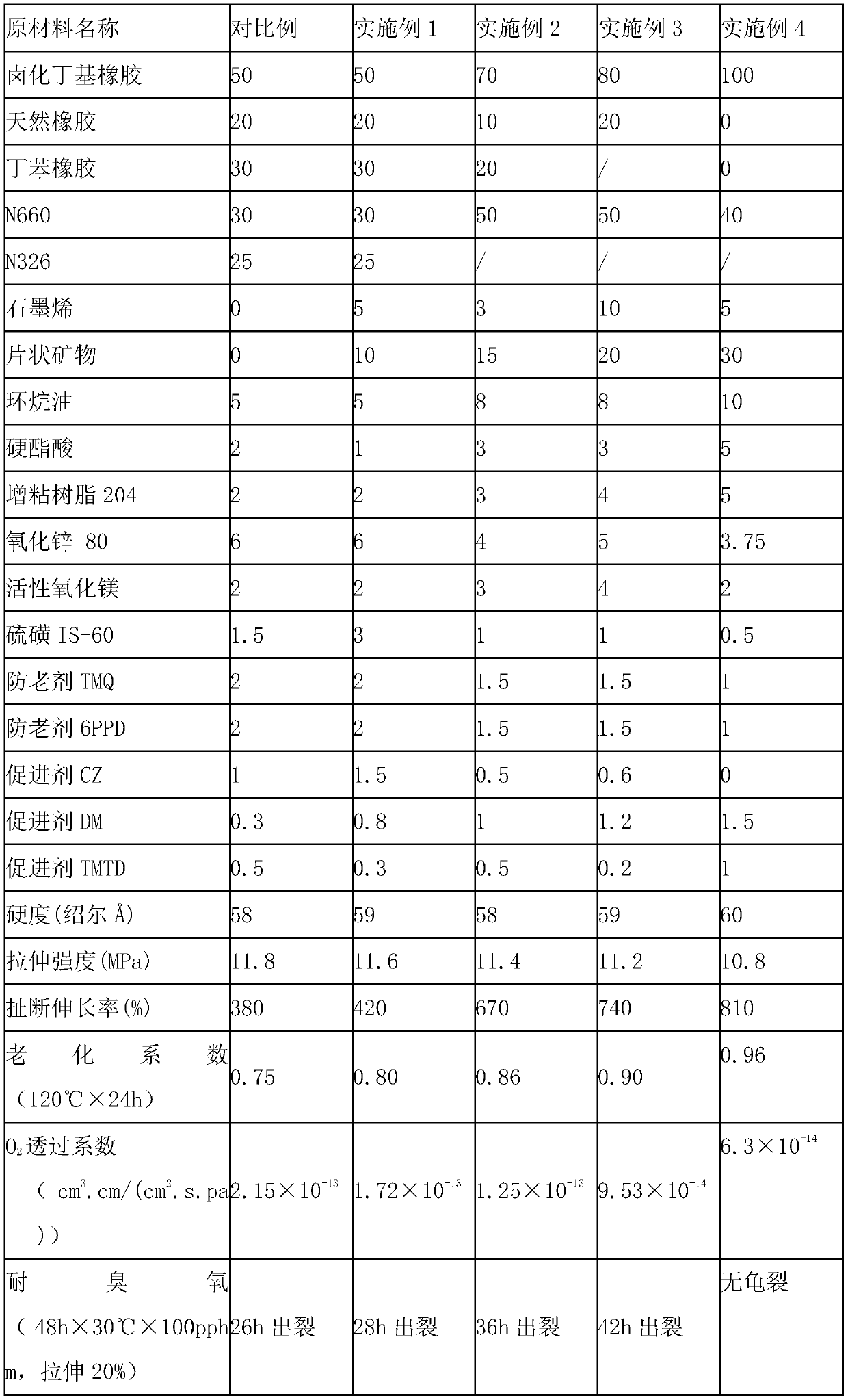

Embodiment 1

[0039] The present embodiment contains graphene-containing aircraft tire sealing layer sizing material, and the sizing material raw material comprises the following components by weight:

[0040] 50 parts of halogenated butyl rubber, 20 parts of natural rubber, 30 parts of styrene-butadiene rubber, 30 parts of carbon black N660, 25 parts of carbon black N326, 5 parts of graphene, 10 parts of flake minerals, 2 parts of activated magnesium oxide, naphthenic oil 5 parts, 1 part of stearic acid, 6 parts of zinc oxide-80, 2 parts of antioxidant TMQ, 2 parts of antioxidant 6PPD, 2 parts of tackifying resin 204, 3 parts of sulfur IS-60, 1.5 parts of accelerator CZ, accelerator 0.8 parts of DM, 0.3 parts of accelerator TMTD.

[0041] The preparation method of the above-mentioned graphene-containing aircraft tire sealing layer compound adopts a two-stage mixing method of an internal mixer, and comprises the following steps:

[0042]Step 1, masterbatch mixing: set the speed of the inte...

Embodiment 2

[0046] The present embodiment contains graphene-containing aircraft tire sealing layer sizing material, and the sizing material raw material comprises the following components by weight:

[0047] 70 parts of halogenated butyl rubber, 10 parts of natural rubber, 20 parts of styrene-butadiene rubber, 50 parts of carbon black N660, 3 parts of graphene, 15 parts of flake minerals, 3 parts of activated magnesium oxide, 8 parts of naphthenic oil, stearic acid 3 parts, 4 parts of zinc oxide-80, 1.5 parts of anti-aging agent TMQ, 1.5 parts of anti-aging agent 6PPD, 3 parts of tackifying resin 204, 1 part of sulfur IS-60, 0.5 parts of accelerator CZ, 1 part of accelerator DM, accelerator TMTD 0.5 parts.

[0048] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com