Macromolecular heat conduction composite material and preparation method thereof

A technology of thermally conductive composite materials and polymer materials, applied in the field of materials, can solve the problems of not increasing but decreasing thermal conductivity, easy formation of holes, and poor processability, etc., to promote close packing, dense internal structure and tight contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Mix 10g of graphite (10000 mesh), 15g of simethicone oil (auxiliary, the same below), 10g of raw silicone rubber, and 1g of vulcanizing agent in a mortar, then transfer the mixture to a centrifuge tube, and centrifuge at 10000rpm for 30 Minutes, open the cover of the centrifuge tube, put it into a blast oven, vulcanize at 80°C for 1 hour, and vulcanize at 120°C for 2 hours to prepare a graphite / silicone rubber heat-conducting composite material.

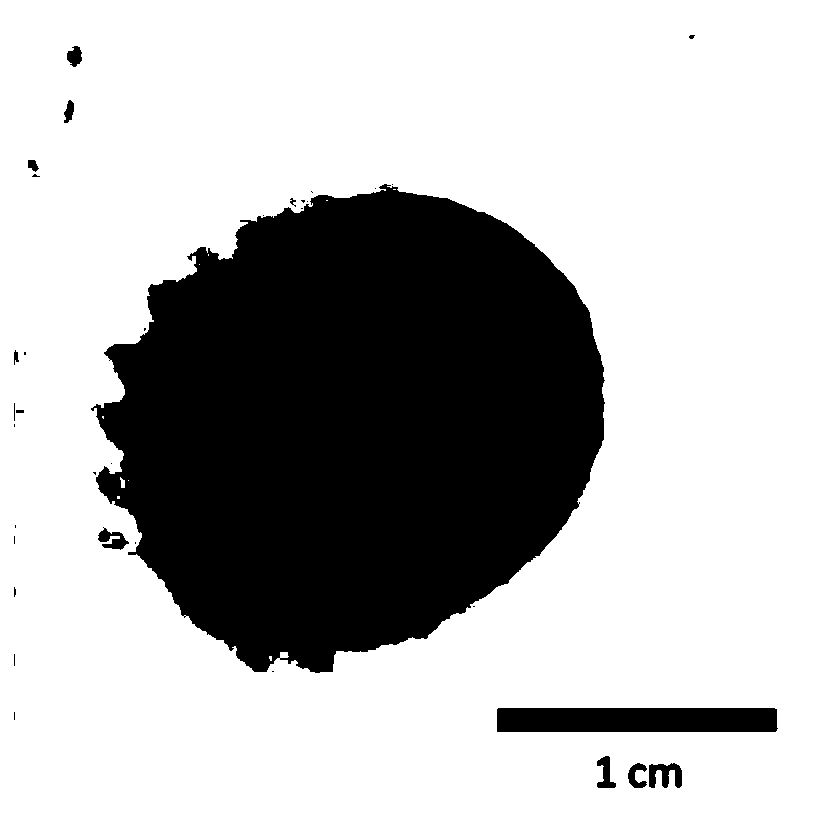

[0048] figure 1 A digital photograph of a graphite / silicone thermally conductive composite in a centrifuge tube after vulcanization.

[0049] The above composite material was taken out from the centrifuge tube and sliced. figure 2 Digital photograph of a slice (thickness 2mm) of graphite / silicone rubber thermally conductive composite. It can be seen that the material is generally dense and has no obvious pores.

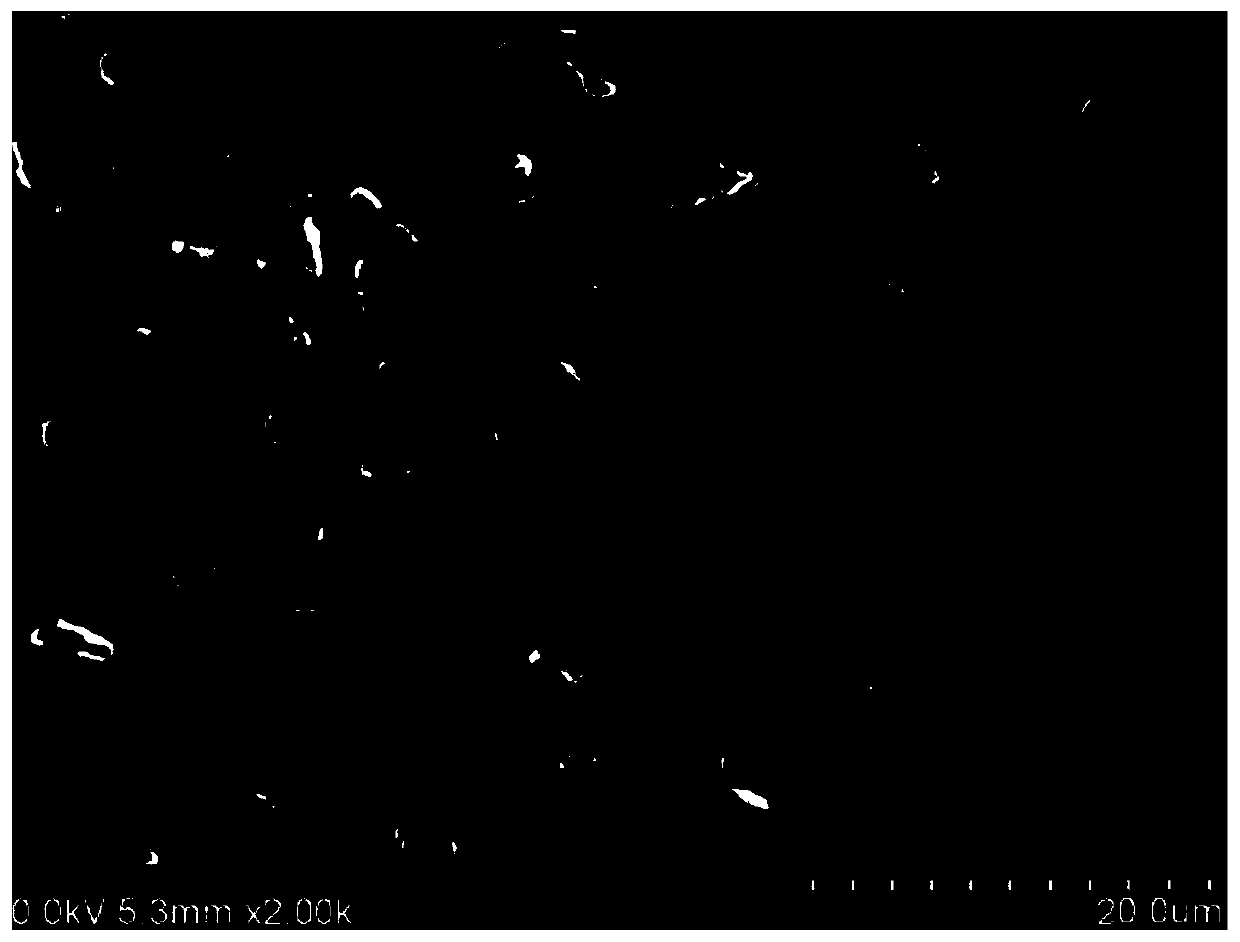

[0050] image 3 It is a scanning electron microscope picture of the cross-section of the graphite / silicone ru...

Embodiment 2

[0053] Mix 100g spherical alumina (average particle size 20 μm), 16g epoxy resin prepolymer and 4g curing agent in a beaker, then transfer the mixture to a centrifuge tube, centrifuge at 6000rpm for 20 minutes, and open the centrifuge tube cover , placed in a blast oven, vulcanized at 60°C for 2 hours, and vulcanized at 120°C for 2 hours to prepare an alumina / epoxy resin thermally conductive composite material.

[0054] Figure 4 It is a scanning electron microscope picture of the cross-section of the alumina / epoxy resin thermally conductive composite material, and it can be seen that the alumina particles form relatively close contacts in the epoxy resin.

[0055] The thermal conductivity of the alumina / epoxy resin thermally conductive composite was tested by the steady-state heat flow method, and it was 2.5W / mK.

Embodiment 3

[0057] Mix 5g spherical boron nitride (average particle size 18μm), 8g simethicone oil, 4.8g raw silicone rubber and 0.2g vulcanizing agent in a beaker, then transfer the mixture to a centrifuge tube and centrifuge at 10000rpm for 40 minutes , open the cover of the centrifuge tube, put it into a blast oven, vulcanize at 80°C for 1 hour, and vulcanize at 120°C for 2 hours to prepare a boron nitride / silicone rubber heat-conducting composite material. Take out and slice.

[0058] Figure 5 It is a digital photo of a slice (thickness 2mm) of the above-mentioned boron nitride / silicone rubber heat-conducting composite material.

[0059] The thermal conductivity of the above-mentioned boron nitride / silicone rubber thermal conductive composite material was tested by a steady-state heat flow method, and it was 4.5 W / mK. In contrast, the thermal conductivity of the boron nitride / silicone rubber thermally conductive composite obtained from the mixture without centrifugation was 2.5 W / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com