Corynebacterium glutamicum engineering bacterium and application thereof in preparation of L-tryptophan

A technology of Corynebacterium glutamicum and tryptophan, applied in the biological field, can solve the problem that the production strain cannot be used for bacterial protein application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

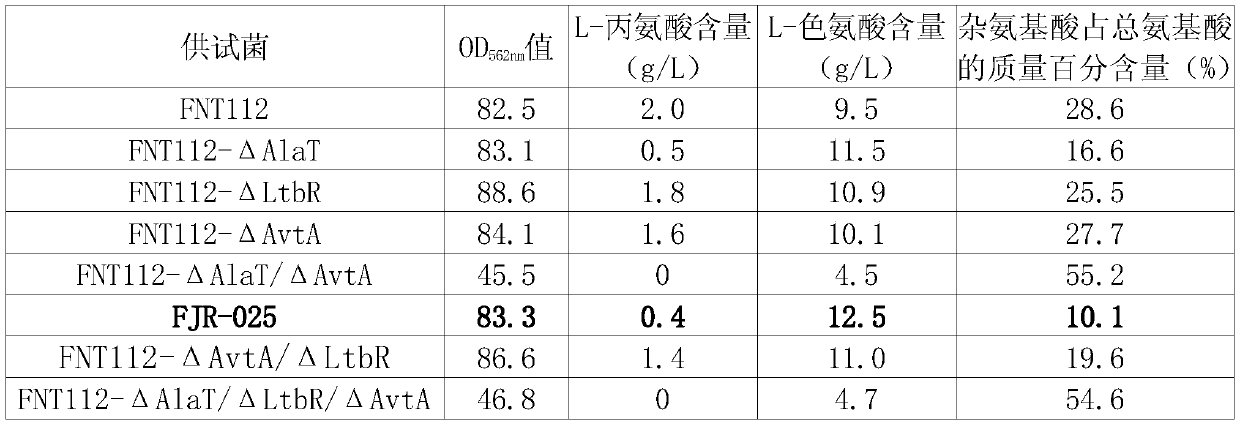

Examples

Embodiment 1

[0065] Embodiment 1, construction of alanine transaminase knockout module

[0066] 1. Construction of alanine aminotransferase (AlaT) knockout module

[0067] In Corynebacterium glutamicum FNT112, the AlaT gene is shown in sequence 2 of the sequence listing, and encodes the AlaT protein shown in sequence 1 of the sequence listing.

[0068] 1. Take Corynebacterium glutamicum FNT112 and extract genomic DNA.

[0069] 2. Using the genomic DNA obtained in step 1 as a template, a primer pair composed of alaT-P1 and alaT-P2 is used for PCR amplification, and the amplified product is recovered.

[0070] alaT-P1: 5'- GAATTC GTGACTACAGACAAGCGCAAAACCTC-3';

[0071] alaT-P2: 5'-AACTACAGACCTAGAACCTATTGAGGAGTGCTTGGGTGGTCATG-3'.

[0072] 3. Using the genomic DNA obtained in step 1 as a template, a primer pair consisting of alaT-P3 and alaT-P4 is used for PCR amplification, and the amplified product is recovered.

[0073] alaT-P3: 5'-TAGGTTCTAGGTCTGTAGTTACTGGACCAAAGCAATACGCACGTGG-3';

...

Embodiment 2

[0092] Example 2, Construction of Leucine and Tryptophan Synthesis Regulator (LtbR) Knockout Module

[0093] In Corynebacterium glutamicum FNT112, the LtbR gene is shown in nucleotides 138-845 of Sequence 6 in the Sequence Listing, and encodes the LtbR protein shown in Sequence 5 in the Sequence Listing.

[0094] 1. Take Corynebacterium glutamicum FNT112 and extract genomic DNA.

[0095] 2. Using the genomic DNA obtained in step 1 as a template, perform PCR amplification with a primer pair composed of ltbR-P1 and ltbR-P2, and recover the amplified product.

[0096] ltbR-P1: 5'- GAATTC atgaccttgaaatacacggtgaag-3';

[0097]ltbR-P2: 5'-AACTACAGACCTAGAACCTAATGCAGGGTCAGCAGCGCGC-3'.

[0098] 3. Using the genomic DNA obtained in step 1 as a template, perform PCR amplification with a primer pair composed of ltbR-P3 and ltbR-P4, and recover the amplified product.

[0099] ltbR-P3: 5'-TAGGTTCTAGGTCTGTAGTTagcgccgcgtgcacccaatg-3';

[0100] ltbR-P4: 5'- GTC GAC ATATCGTTTCATGGGACAGTA...

Embodiment 3

[0105] Embodiment 3, the construction of Corynebacterium glutamicum engineering strain

[0106] 1. Construction of AlaT Gene Modified Strains

[0107] 1. Transform Corynebacterium glutamicum FNT112 with the recombinant plasmid pk18ΔAlaT by electric shock method. Immediately after the electric shock, add it to the SOC medium preheated at 45°C, and cultivate it at 42°C and 200rpm for 1 hour, then at 37°C and 120-150rpm Incubate for 3-5 hours. An Eppendorf electroporator was used. Shock conditions: 1800V, shock time 4-5ms.

[0108] 2. After completing step 1, take the bacterial liquid, spread it on the LBG medium plate containing 25 μg / mL kanamycin sulfate, and culture it upside down at 30°C for 24-30 hours. The clones grown on the plate were the ones that successfully underwent the first recombination. The first recombination, that is, the recombinant plasmid pk18ΔAlaT is inserted into the chromosome as a whole by means of single exchange.

[0109] 3. After completing step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com