Filter electrode and manufacturing method thereof

A technology for filter electrodes and manufacturing methods, which is applied in liquid chemical plating, metal material coating process, coating, etc., and can solve problems such as inability to obtain qualified solderable coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for processing electrode metallization of a multi-terminal filter, specifically comprising steps 1-6 above.

[0054] The parameters of step 3 are as follows:

[0055] EDTA mass concentration 25%, treatment time 4min;

[0056] The relevant parameters of step 4 are as follows:

[0057] Nickel sulfate 30g / L, sodium hypophosphite 25g / L, sodium citrate 70g / L;

[0058] Glycine 50g / L, sodium hydroxide 18g / L, lead nitrate 30mg / L;

[0059] Temperature 85℃, pH value 4.9, treatment time 12min;

[0060] The relevant parameters of step 5 are as follows:

[0061] Gold sodium sulfite 2g / L, sodium sulfite 15g / L, sodium thiosulfate 12g / L;

[0062] Borax 10g / L, reaction temperature 75°C, pH 7.0.

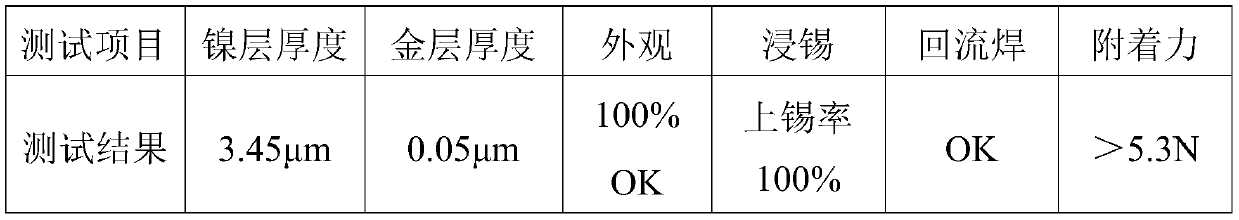

[0063] The products metallized by this process were tested, and the test results are shown in Table 1.

[0064] Table 1

[0065]

Embodiment 2

[0067] A method for processing electrode metallization of a multi-terminal filter, specifically comprising steps 1-6 above.

[0068] The parameters of step 3 are as follows:

[0069] EDTA mass concentration 40%, treatment time 8min;

[0070] The relevant parameters of step 4 are as follows:

[0071] Nickel sulfate 30g / L, sodium hypophosphite 25g / L, sodium citrate 70g / L;

[0072] Glycine 50g / L, sodium hydroxide 18g / L, lead nitrate 10mg / L;

[0073] Temperature 82℃, pH value 5.1, treatment time 10min;

[0074] The relevant parameters of step 5 are as follows:

[0075] Gold sodium sulfite 2g / L, sodium sulfite 15g / L, sodium thiosulfate 12g / L;

[0076] Borax 10g / L, reaction temperature 75°C, pH 7.0.

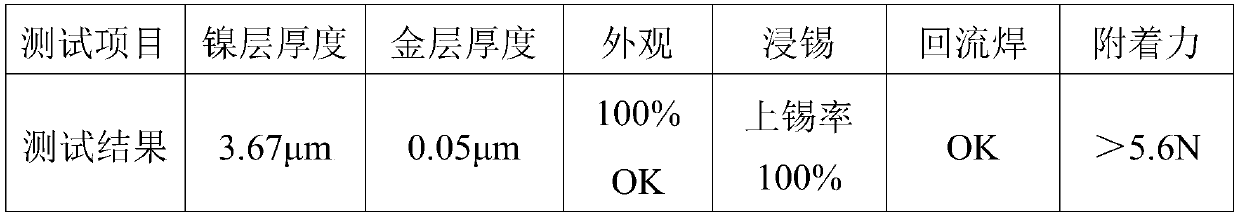

[0077] The products metallized by this process were tested, and the test results are shown in Table 2.

[0078] Table 2

[0079]

Embodiment 3

[0081] A method for processing electrode metallization of a multi-terminal filter, specifically comprising steps 1-6 above.

[0082] The parameters of step 3 are as follows:

[0083] EDTA mass concentration 30%, treatment time 10min;

[0084] The relevant parameters of step 4 are as follows:

[0085] Nickel sulfate 30g / L, sodium hypophosphite 25g / L, sodium citrate 70g / L;

[0086] Glycine 50g / L, sodium hydroxide 18g / L, lead nitrate 50mg / L;

[0087] Temperature 90℃, pH value 4.8, treatment time 10min;

[0088] The relevant parameters of step 5 are as follows:

[0089] Gold sodium sulfite 2g / L, sodium sulfite 15g / L, sodium thiosulfate 12g / L;

[0090] Borax 10g / L, reaction temperature 75°C, pH 7.0.

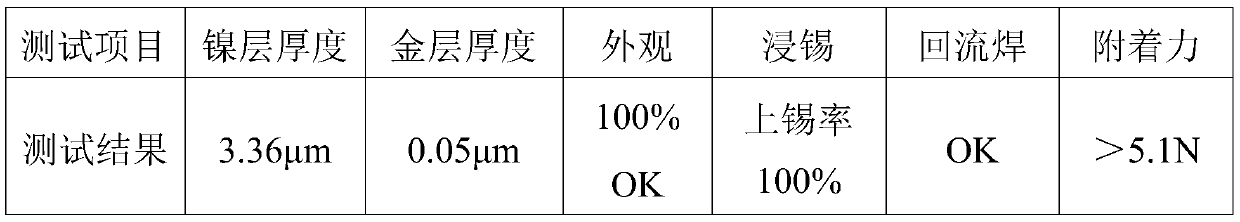

[0091] The products metallized by this process were tested, and the test results are shown in Table 3.

[0092] table 3

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com