Cutter system for numerically-controlled cutting bed

A technology of cutting knife and cutting machine, applied in the field of cutting knife system, can solve the problems of increasing the friction frequency between the blade and the cloth, increasing the reciprocating frequency of the blade, and the working ability of the equipment is not strong, so as to eliminate the unbalanced force, increase the noise and Vibration, vibration and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

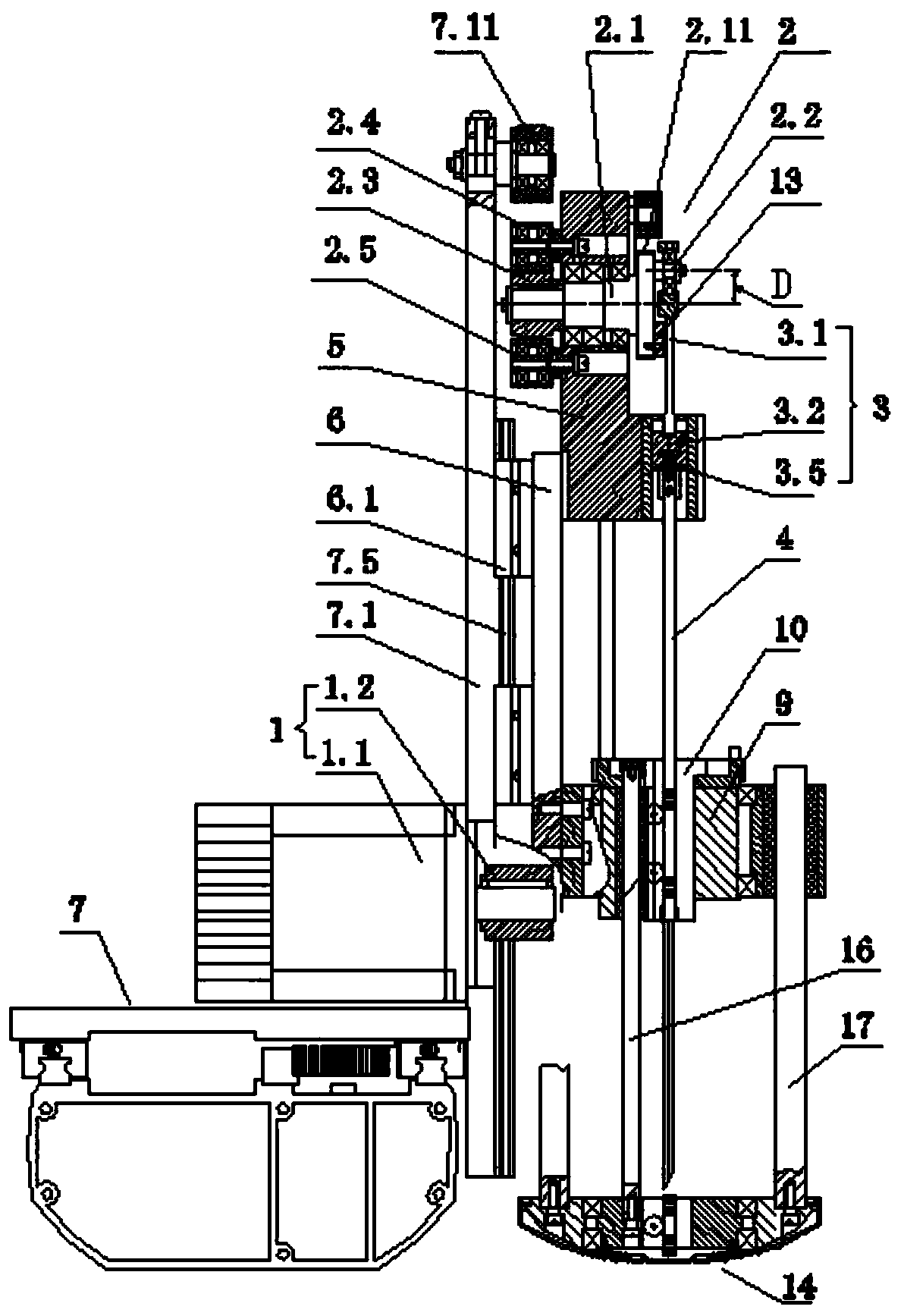

[0084] As a preferred example of the present invention, such as Figure 1 to Figure 4 As shown, the present embodiment provides a cutting knife system for a CNC cutting machine, including a power mechanism 1 and an eccentric wheel mechanism 2, and the power mechanism 1 and the eccentric wheel mechanism 2 are connected in transmission;

[0085] Such as figure 1 , Figure 4 and Figure 7 As shown, the eccentric wheel mechanism 2 includes an eccentric shaft, on which a balance wheel device 12 is arranged, and the balance wheel device 12 is connected to the eccentric shaft through transmission. The eccentric shaft includes an eccentric main shaft 2.1, and an eccentric inertial shaft 2.2 for socketing the connecting rod assembly 3 is provided on the end face of the power output end of the eccentric main shaft 2.1. The eccentric distance D between the eccentric main shaft 2.1 and the eccentric inertial shaft 2.2 is 15- 30mm, the eccentric main shaft 2.1 is provided with a first c...

Embodiment 2

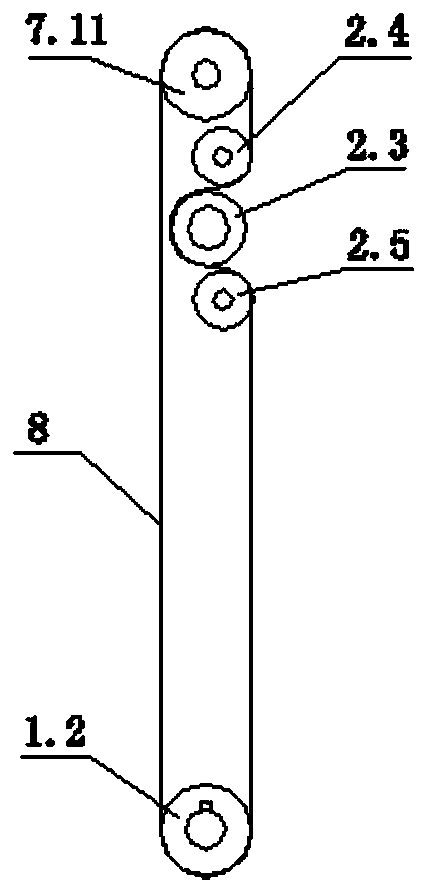

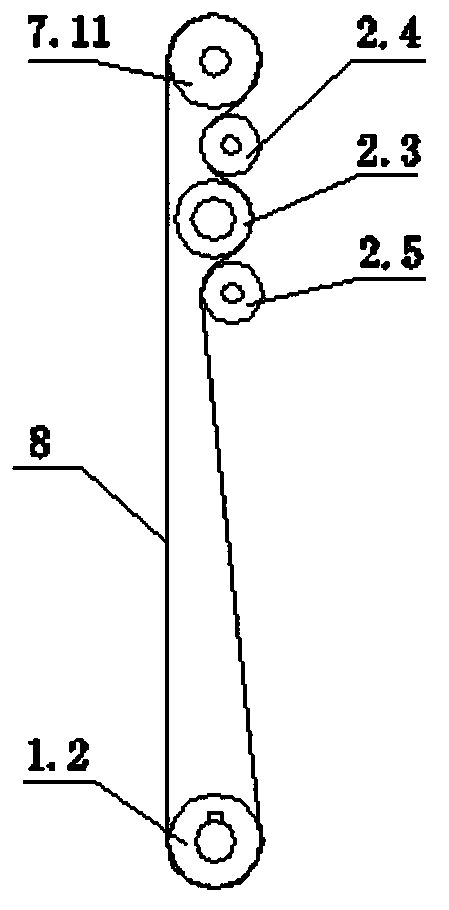

[0102] Such as Figure 5 and Figure 6 As shown, the structure of this embodiment is similar to that of Embodiment 1, and the difference is that the power mechanism 1 and the eccentric wheel mechanism 2 are relatively fixedly arranged, and the first main shaft wheel 2.3 of the power mechanism 1 and the eccentric wheel mechanism 2 are engaged by gears or Connected by conveyor belt drive.

[0103]The power mechanism 1 is a main shaft motor 1.1, and the eccentric main shaft 2.1 of the eccentric wheel mechanism 2 is fixed on the main shaft mounting seat 5 through bearings, and the main shaft mounting seat 5 is connected with the vertical frame 7.1 arranged above the CNC cutting machine through the slide plate 6 Sliding connection; specifically, the linear slider (not shown) provided on the side of the slide plate 6 facing the vertical frame 7.1 is matched with the linear guide rail (not shown) provided on the side of the vertical frame 7.1 facing the slide plate 6 slide. The ma...

Embodiment 3

[0107] The structure of this embodiment is similar to Embodiment 1, the difference is that the structure of the balance wheel device 12 is different, such as Figure 12 and Figure 13 As shown, the balance wheel device 12 includes two balance wheels 12.1, the two balance wheels 12.1 are symmetrically arranged on the left and right sides of the axis line of the eccentric main shaft 2.1, and the two balance wheels 12.1 are arranged on the main shaft mounting seat 5 On the side close to the power output end of the eccentric main shaft 2.1 (that is, the side where the main shaft mounting seat 5 is away from the vertical frame), the two balance wheels 12.1 are in transmission connection with the second main shaft wheel 2.11 provided at the power output end of the eccentric main shaft 2.1; A second tensioning wheel 12.4 is provided above one balance wheel 12.1, and the second tensioning wheel 12.4 is fixedly arranged on the main shaft mounting base 5. The second tensioning wheel 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com