High-bonding-strength LCP substrate and preparation method

A substrate and strength technology, applied in circuit substrate materials, chemical instruments and methods, printed circuit manufacturing, etc., can solve the problems of unimproved LCP and copper foil adhesion, etc., to achieve high-frequency high-speed transmission, reduce signal loss, The effect of low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

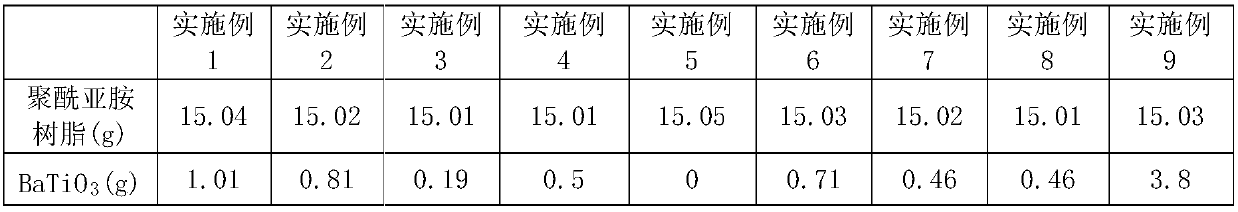

Examples

Embodiment approach

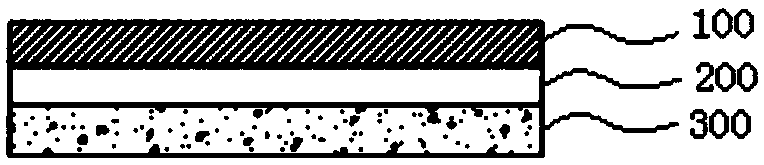

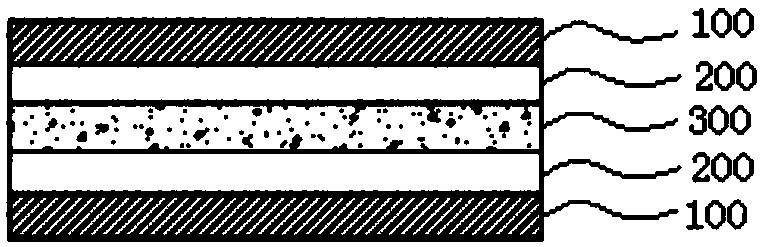

[0043] Implementation mode: a high bonding strength LCP substrate, such as Figure 1 to Figure 2 As shown, it includes at least one copper foil layer 100, at least one low dielectric adhesive layer 200, and an LCP layer 300. The low dielectric adhesive layer is located between the copper foil layer and the LCP layer and is bonded to each other. The copper foil layer and the LCP layer, the low-dielectric adhesive layer refers to a glue layer with a Dk value of 2.0-4.0 (10 GHz) and a Df value of 0.001-0.010 (10 GHz); the LCP layer refers to Dk LCP layer with a value of 2.5-4.0 (10GHz) and a Df value of 0.001-0.010 (10GHz);

[0044] The thickness of each copper foil layer is 1-35 μm; the thickness of each low-dielectric adhesive layer is 1-7 μm; the thickness of the LCP layer is 12-75 μm;

[0045] The low dielectric adhesive layer includes at least one of component A and component B, and the component A includes ceramic powder, sintered silica, Teflon, fluorine-based resin, PEEK (pol...

Embodiment approach 1

[0054] Embodiment 1: A high bonding strength LCP substrate, such as figure 1 As shown, the LCP substrate is an LCP single-sided copper foil substrate, and the LCP single-sided copper foil substrate is composed of a copper foil layer 100, a low-dielectric adhesive layer 200, and an LCP layer 300, which are sequentially from top to bottom Are the copper foil layer 100, the low dielectric adhesive layer 200 and the LCP layer 300; the thickness of the LCP single-sided copper foil substrate is 14-117 μm.

[0055] The preparation method of the LCP single-sided copper foil substrate of Embodiment 1 is as follows:

[0056] Step 1. Coat the precursor of the low dielectric adhesive layer on one side of the copper foil layer, and remove the solvent at 60-180°C;

[0057] Step 2: Coat the precursor of the LCP layer on the lower surface of the low dielectric adhesive layer, remove the solvent at 60-180°C, and then at 240-260°C (preferably 250°C), Annealing (tempering) for 8-12 hours (preferably 1...

Embodiment approach 2

[0058] Embodiment 2: A high bonding strength LCP substrate, such as figure 2 As shown, the LCP substrate is an LCP double-sided copper foil substrate, and the LCP double-sided copper foil substrate is composed of two copper foil layers 100, two low-dielectric adhesive layers 200, and an LCP layer 300, from top to bottom The thickness of the copper foil layer 100, the low dielectric adhesive layer 200, the LCP layer 300, the low dielectric adhesive layer 200, and the copper foil layer 100 in sequence; the thickness of the LCP double-sided copper foil substrate It is 16-159μm.

[0059] The preparation method of the LCP double-sided copper foil substrate of Embodiment 2 is one of the following two methods:

[0060] The first method includes the following steps:

[0061] Step 1. Coat the precursor of the low dielectric adhesive layer on one side of the copper foil layer, and remove the solvent at 60-180°C;

[0062] Step 2: Coat the precursor of the LCP layer on the surface of the low di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com