Multifunctional signal conversion cabinet

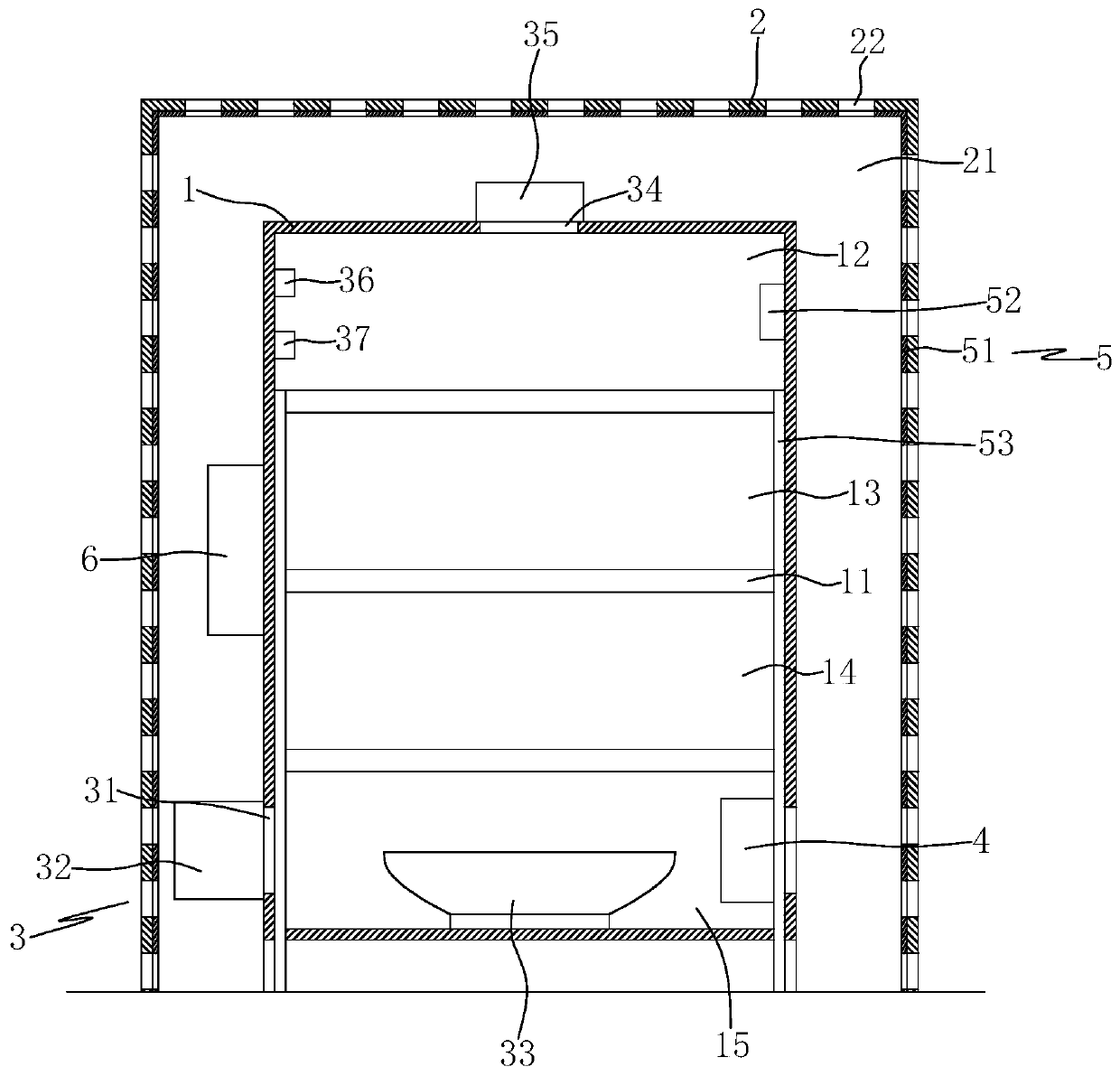

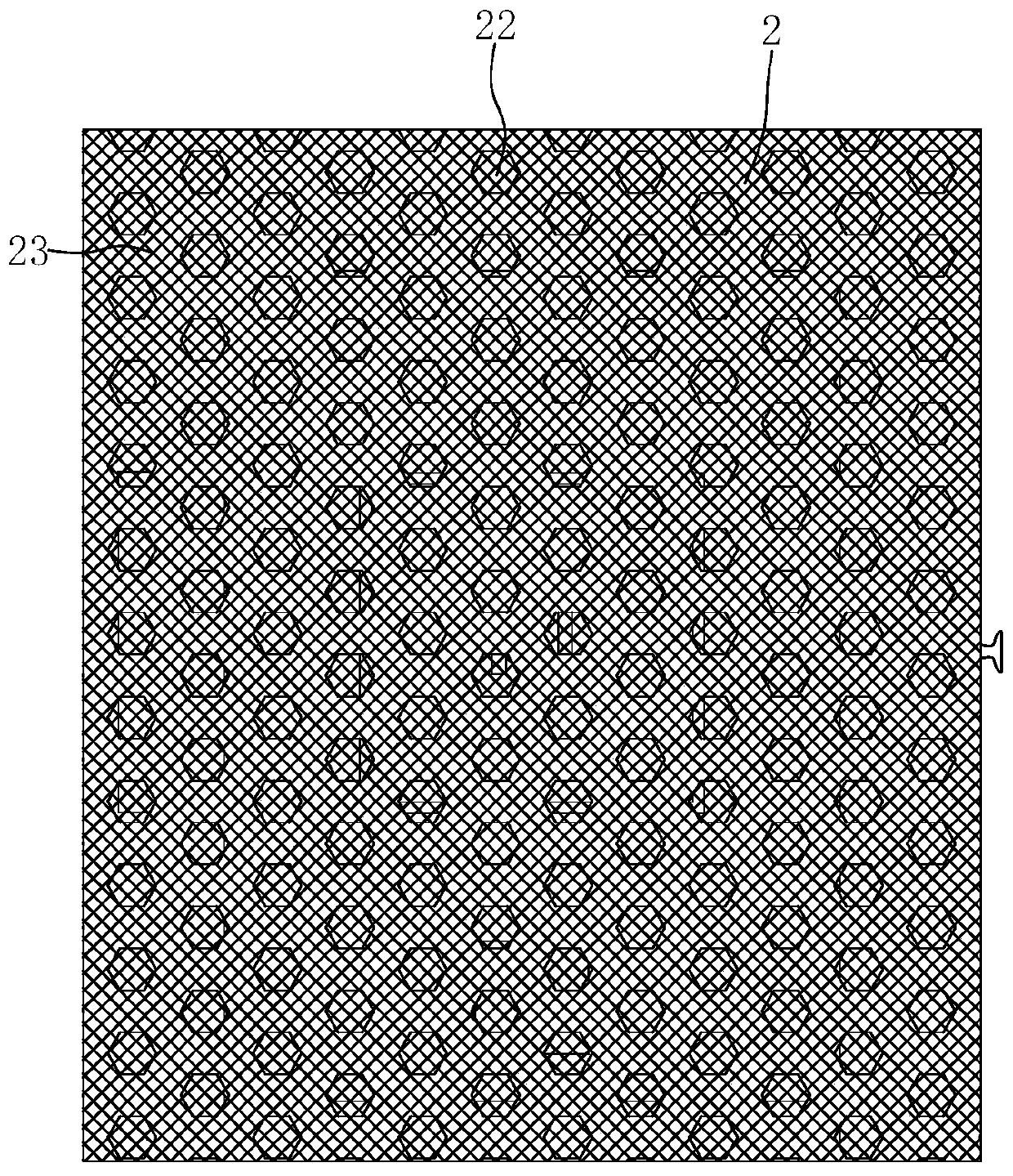

A conversion cabinet, multi-functional technology, applied in the direction of electrical components, substation/distribution device casing, substation/switchgear cooling/ventilation, etc., can solve the problem of fast heat dissipation and moisture-proof treatment of signal conversion cabinet, and achieve good heat dissipation effect. and dehumidification effect, improve heat exchange efficiency, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

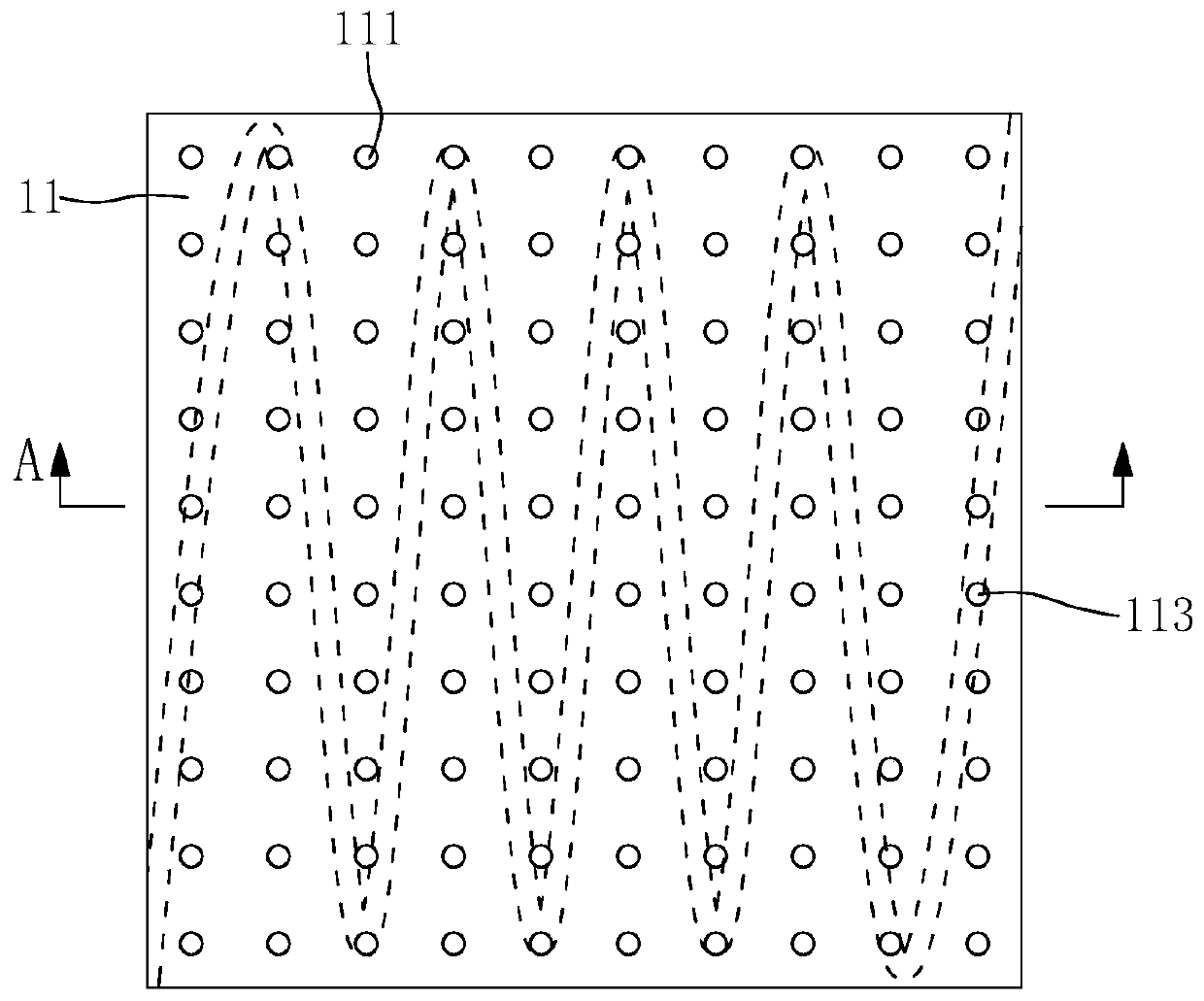

[0044] The phase change material 1132 includes the following raw materials in parts by weight: 15 parts of gypsum, 15 parts of limestone powder, 12 parts of calcium hydroxide, 5 parts of calcium stearate, 18 parts of acetic acid, 16 parts of borax, 10 parts of bentonite, and 8 parts of potassium chloride , 10 parts of yttrium oxide.

Embodiment 2

[0046] The phase change material 1132 includes the following raw materials in parts by weight: 20 parts of gypsum, 10 parts of limestone powder, 6 parts of calcium hydroxide, 8 parts of calcium stearate, 12 parts of acetic acid, 10 parts of borax, 8 parts of bentonite, and 15 parts of potassium chloride , 15 parts of yttrium oxide.

Embodiment 3

[0048] The phase change material 1132 includes the following raw materials in parts by weight: 18 parts of gypsum, 12 parts of limestone powder, 9 parts of calcium hydroxide, 7 parts of calcium stearate, 15 parts of acetic acid, 13 parts of borax, 8 parts of bentonite, and 12 parts of potassium chloride , 12 parts of yttrium oxide.

[0049] The phase-change material 1132 is composed of the above-mentioned raw materials. The material is non-corrosive, and the packaging and the metal tube 1131 are not prone to leakage and pollution. At the same time, the phase-change latent heat is high, the thermal conductivity is high, and the phase-change temperature is appropriate. 1, the temperature inside is adjusted without external energy and action mechanism, which further improves the safety of the conversion cabinet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com