Preparation scheme of novel high-transmittance vanadium dioxide thin film element

A technology of vanadium dioxide and high transmittance, which is applied in the field of physics, can solve the problems of low transmittance of thin films, achieve the effect of increasing transmittance, reducing dependence, and reducing the probability of defect generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

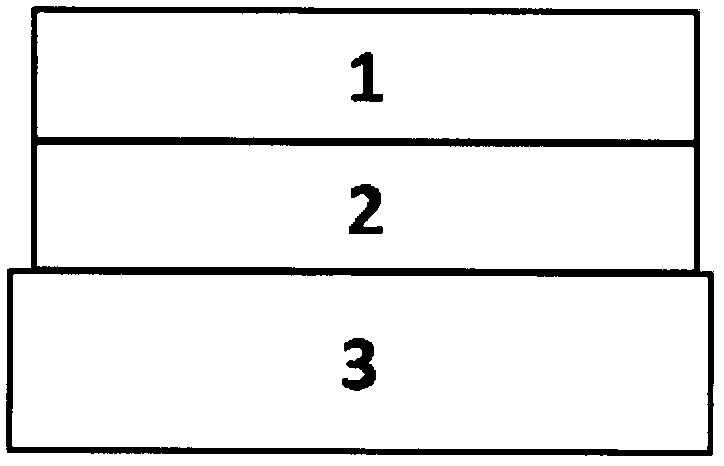

Image

Examples

Embodiment 1

[0048] This embodiment provides a vanadium dioxide double-layer membrane element, which comprises a vanadium dioxide double-layer membrane system and an element substrate carrying the vanadium dioxide double-layer membrane system.

[0049] The specific steps of the preparation method of the vanadium dioxide double-layer membrane element are as follows:

[0050] Step 1. Theoretical design and optimization of the spectral performance of the vanadium dioxide bilayer film system

[0051] Using the existing film system analysis software, respectively analyze the influence trend and change rule of the sputtering process parameters on the performance of the graded refractive index material and the performance of the vanadium dioxide film, so as to evaluate the tolerance of the process preparation; The required gradient refractive index material film layer refractive index distribution prepared by the process; on this basis, the vanadium dioxide double-layer film system is designed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com