Hydrogen sulfide gas source collaborated sludge bioleaching reactor

A bioleaching and hydrogen sulfide technology, applied in the field of environmental pollution control, can solve the problems of difficult collection and resource utilization of sewage plant odor, unstable biomass of bacterial flora, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

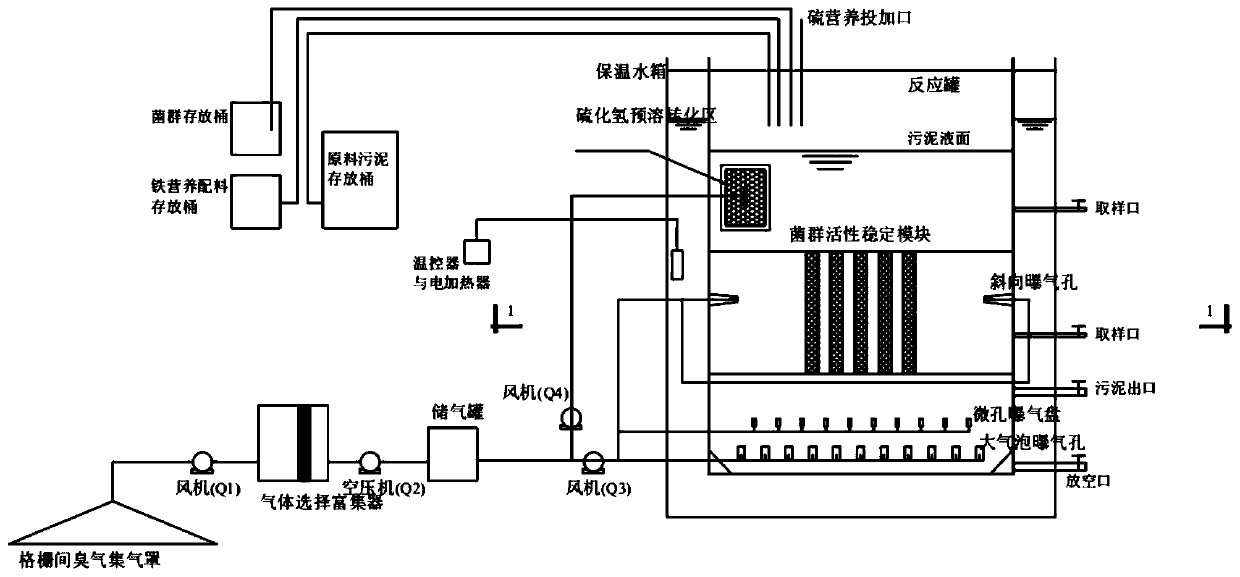

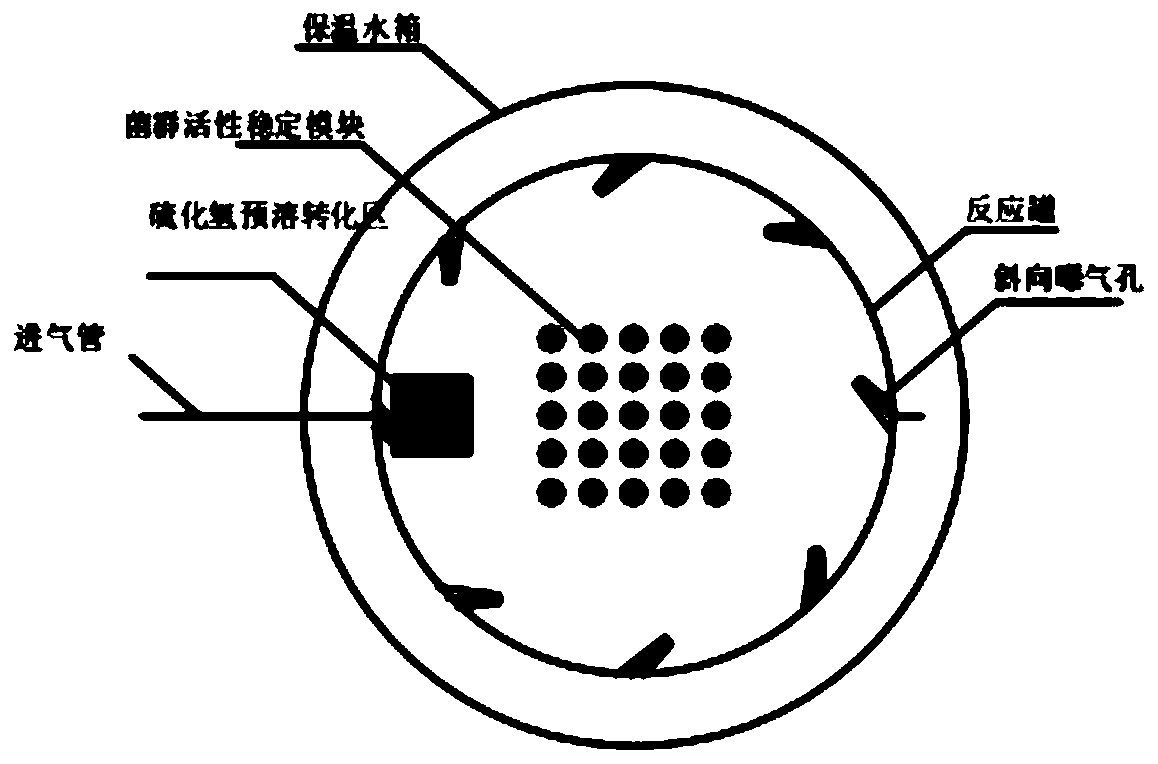

[0065] A hydrogen sulfide gas source synergistic sludge bioleaching reactor includes the following parts: odor collection system, gas selective enrichment device, gas storage tank, hydrogen sulfide pre-dissolution conversion zone, aeration system, reaction tank, and reaction raw material dosing system, constant temperature control system;

[0066] The odor collection system is composed of a gas collection hood, a gas delivery pipe, and a fan Q1. The gas collection hood is set above the water inlet between the grills or the sludge concentration tank in the sewage treatment plant to collect the water inlet between the grills or the sludge concentration One end of the gas delivery pipe communicates with the gas collection hood, and the other end of the gas delivery pipe communicates with the gas selection enricher. The fan Q1 is set on the gas delivery pipe and pumps the odor into the gas selection enricher through the air delivery pipe. , the concentration of hydrogen sulfide in...

Embodiment 2

[0110] A hydrogen sulfide gas source synergistic sludge bioleaching reactor includes the following parts: odor collection system, gas selective enrichment device, gas storage tank, hydrogen sulfide pre-dissolution conversion zone, aeration system, reaction tank, and reaction raw material dosing system, constant temperature control system;

[0111] The odor collection system is composed of a gas collection hood, a gas delivery pipe, and a fan Q1. The gas collection hood is set above the water inlet between the grills or the sludge concentration tank in the sewage treatment plant to collect the water inlet between the grills or the sludge concentration One end of the gas delivery pipe communicates with the gas collection hood, and the other end of the gas delivery pipe communicates with the gas selection enricher. The fan Q1 is set on the gas delivery pipe and pumps the odor into the gas selection enricher through the air delivery pipe. , the concentration of hydrogen sulfide in...

Embodiment 3

[0155] A hydrogen sulfide gas source synergistic sludge bioleaching reactor includes the following parts: odor collection system, gas selective enrichment device, gas storage tank, hydrogen sulfide pre-dissolution conversion zone, aeration system, reaction tank, and reaction raw material dosing system, constant temperature control system;

[0156] The odor collection system is composed of a gas collection hood, a gas delivery pipe, and a fan Q1. The gas collection hood is set above the water inlet between the grills or the sludge concentration tank in the sewage treatment plant to collect the water inlet between the grills or the sludge concentration One end of the gas delivery pipe communicates with the gas collection hood, and the other end of the gas delivery pipe communicates with the gas selection enricher. The fan Q1 is set on the gas delivery pipe and pumps the odor into the gas selection enricher through the air delivery pipe. , the concentration of hydrogen sulfide in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com