Method of improving heating efficiency of calcium oxide heat source in self-heating food

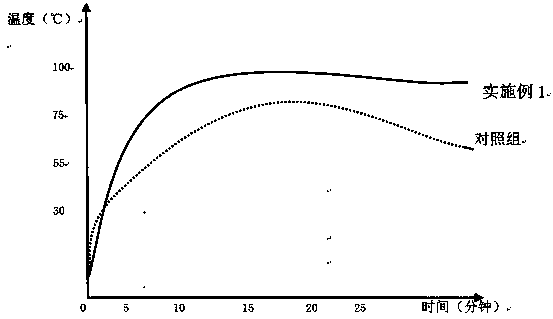

A technology of heating efficiency and calcium oxide, which is applied in food heating containers, packaged foods, and types of packaged items. It can solve problems such as high initial reaction temperature, potential safety hazards, and fast attenuation, and achieve improved heat production rate, safe and convenient use, and The effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for improving the heating efficiency of calcium oxide heat sources in self-heating food, the preferred solution is to use the prepared nano-scale coating agent to coat calcium oxide powder, changing the physical and chemical properties of calcium oxide, reducing Heat loss, optimize the heat transfer rate, and calcinate the prepared coated calcium oxide to further form a modified calcium oxide heat source;

[0018] Specifically, the following steps are included:

[0019] S1: Preparation of coating agent: Weigh 16.5 grams of silicon dioxide and 11.0 grams of graphite oxide and place them in a mortar, grind and mix evenly, and put the mixed grinding materials in a beaker, and add 100-110 ml of ultrapure water into the beaker , ultrasonically disperse for 10 minutes, add 9 ml of hydrochloric acid with a molar concentration of 6.0 mol / liter dropwise under stirring, then place it in a water bath at 60°C, and add 4.50 ml of aqueous hydrogen peroxide solution with a ma...

Embodiment 2

[0022] A method for improving the heating efficiency of calcium oxide heat sources in self-heating food, the preferred solution is to use the prepared nano-scale coating agent to coat calcium oxide powder, changing the physical and chemical properties of calcium oxide, reducing Heat loss, optimize the heat transfer rate, and calcinate the prepared coated calcium oxide to further form a modified calcium oxide heat source;

[0023] Specifically, the following steps are included:

[0024] S1: Preparation of coating agent: Weigh 16.8 grams of silicon dioxide and 11.5 grams of graphite oxide and place them in a mortar, grind and mix them evenly, and put the mixed grinding materials in a beaker, add 105 milliliters of ultrapure water into the beaker, and ultrasonically Disperse for 12 minutes, add 10 ml of hydrochloric acid with a molar concentration of 6.2 mol / liter drop by drop under stirring, then place it in a water bath at 65°C, add 4.8 ml of aqueous hydrogen peroxide solution ...

Embodiment 3

[0027] A method for improving the heating efficiency of calcium oxide heat sources in self-heating food, the preferred solution is to use the prepared nano-scale coating agent to coat calcium oxide powder, changing the physical and chemical properties of calcium oxide, reducing Heat loss, optimize the heat transfer rate, and calcinate the prepared coated calcium oxide to further form a modified calcium oxide heat source;

[0028] Specifically, the following steps are included:

[0029] S1: Preparation of coating agent: Weigh 17.0 grams of silicon dioxide and 13.0 grams of graphite oxide, place them in a mortar, grind and mix them evenly, and put the mixed grinding materials in a beaker, add 110 milliliters of ultrapure water into the beaker, and ultrasonically Disperse for 15 minutes, add 12 ml of hydrochloric acid with a molar concentration of 6.5 mol / liter drop by drop under stirring, then place it in a 70°C water bath, add 5.0 ml of a 30% aqueous hydrogen peroxide solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com