Preparation method of porous g-C3N4 photocatalyst

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of small specific surface area, decreased photocatalytic performance, low light utilization rate, etc., achieve high specific surface area, improve photocatalytic performance, and improve light absorption range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

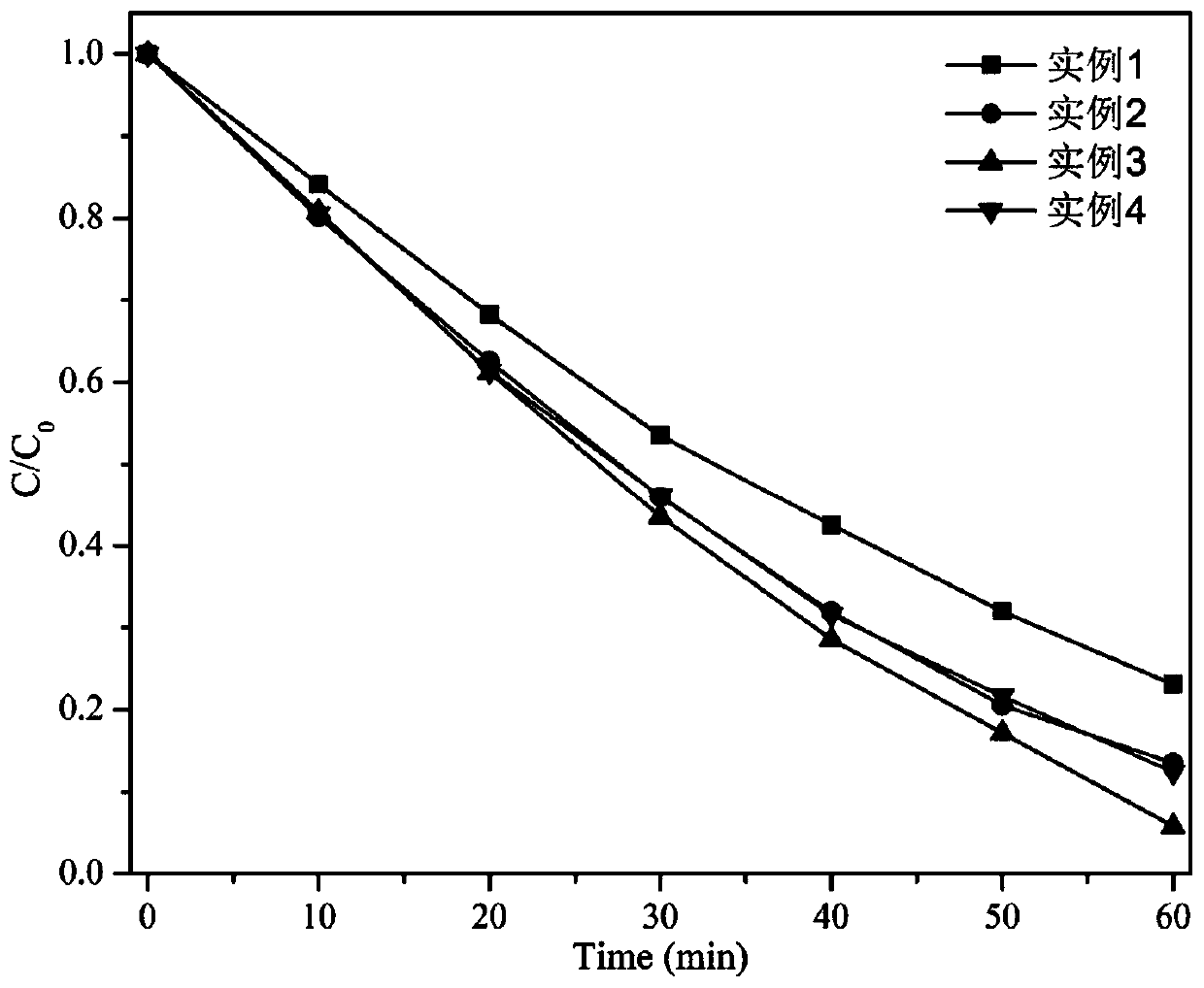

Embodiment 1

[0021] A porous g-C 3 N 4 The preparation method of photocatalyst is characterized in that, comprises the following steps:

[0022] 1) Weigh 0.5g of ammonium oxalate, add it to a 100mL reactor, add 20mL of deionized water, place the reactor in an ultrasonic cleaner for ultrasonic treatment for 20min, and prepare an ammonium oxalate solution.

[0023] 2) Weigh 2.5g of melamine and add it into the ammonium oxalate solution described in step 1) to obtain a mixed suspension.

[0024] The melamine described in step 2) is powder (200 mesh), produced by Chengdu Kelong Chemical Reagent Factory, and the production batch number is 2015041401.

[0025] 3) Ultrasonicate the mixed suspension solution for 60 min. The solid matter in the mixed suspension solution was separated, and the separated solid matter was dried at 80° C. for 6 h.

[0026] 4) Grinding the solid matter to 200 mesh.

[0027] 5) Put the ground solid substance into a corundum crucible with a cover, cover it and put it...

Embodiment 2

[0029] A porous g-C 3 N 4 The preparation method of photocatalyst is characterized in that, comprises the following steps:

[0030] 1) Weigh 0.5g of ammonium oxalate, add it to a 100mL reactor, add 20mL of deionized water, place the reactor in an ultrasonic cleaner for ultrasonic treatment for 20min, and prepare an ammonium oxalate solution.

[0031] 2) Weigh 5 g of melamine and add it into the ammonium oxalate solution described in step 1) to obtain a mixed suspension.

[0032] The melamine described in step 2) is powder (200 mesh), produced by Chengdu Kelong Chemical Reagent Factory, and the production batch number is 2015041401.

[0033] 3) Ultrasonicate the mixed suspension solution for 60 min. The solid matter in the mixed suspension solution was separated, and the separated solid matter was dried at 80° C. for 6 h.

[0034] 4) Grinding the solid matter to 200 mesh.

[0035] 5) Put the ground solid substance into a corundum crucible with a cover, cover it and put it ...

Embodiment 3

[0037] A porous g-C 3 N 4 The preparation method of photocatalyst is characterized in that, comprises the following steps:

[0038] 1) Weigh 0.5g of ammonium oxalate, add it to a 100mL reactor, add 20mL of deionized water, place the reactor in an ultrasonic cleaner for ultrasonic treatment for 20min, and prepare an ammonium oxalate solution.

[0039] 2) Weigh 7.5g of melamine and add it into the ammonium oxalate solution described in step 1) to obtain a mixed suspension.

[0040] The melamine described in step 2) is powder (200 mesh), produced by Chengdu Kelong Chemical Reagent Factory, and the production batch number is 2015041401.

[0041] 3) Ultrasonicate the mixed suspension solution for 60 min. The solid matter in the mixed suspension solution was separated, and the separated solid matter was dried at 80° C. for 6 h.

[0042] 4) Grinding the solid matter to 200 mesh.

[0043] 5) Put the ground solid substance into a corundum crucible with a cover, cover it and put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com