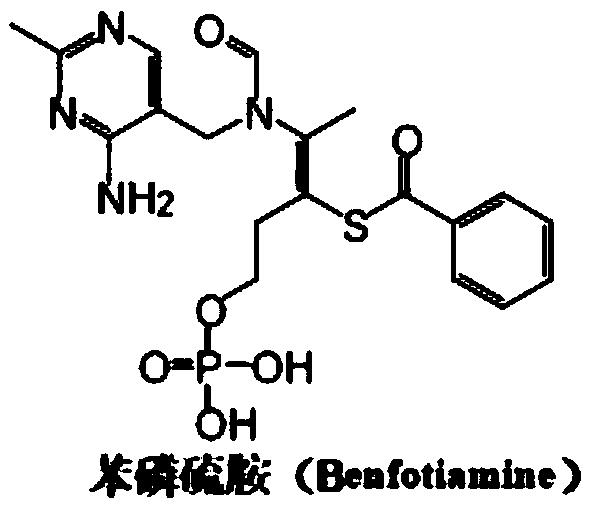

Preparation method of benfotiamine intermediate monophosphothiamine

A technology of benfotiamine and an intermediate, which is applied in the field of organic compound preparation technology, can solve the problems of being unsuitable for industrial scale production, low production efficiency, slow cycle process and the like, and achieves a short production cycle, less waste water and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

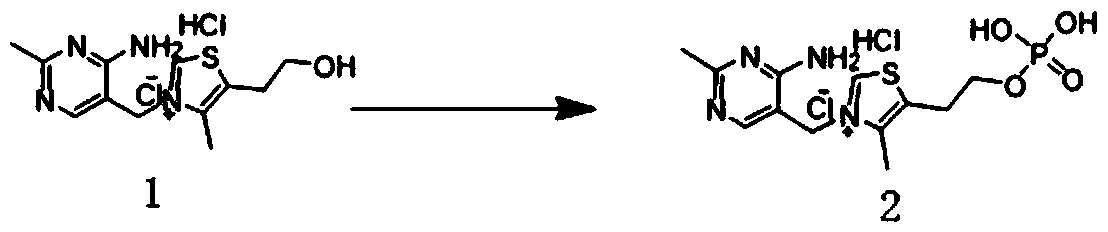

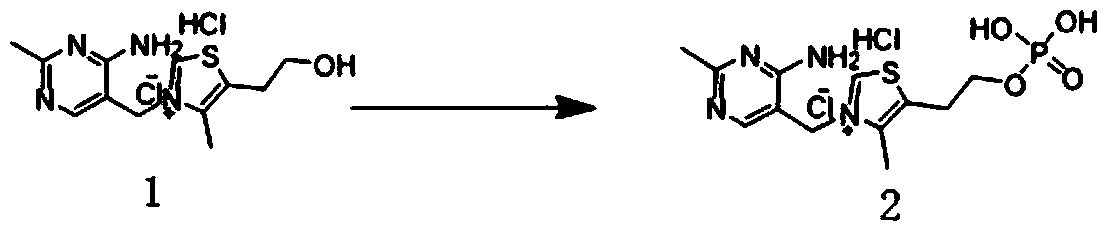

Method used

Image

Examples

Embodiment 1

[0018] Add 21.1 (0.106mol) grams of pyrophosphoric acid and 100.0 grams of toluene in the reaction flask with a mass ratio of 90%, and heat to 80°C. When the temperature in the reaction flask reaches 80°C, add 10.0 grams (0.0265mol) of compound 1 in batches , react at a temperature of 80°C for 2 hours, also at 80°C, add 10.0 g (0.106 mol) of hydrochloric acid solution, maintain 80°C and stir for 1.0 hour, drop to room temperature and separate layers, take the lower layer containing the product and put it in a clean reaction bottle, Add ethanol dropwise to the reaction bottle, filter after crystallization, rinse the filtered solid with 5 mL of ethanol, and dry to obtain 12.4 g of phostiamine, moisture: 1.2%, purity: 96.25%.

Embodiment 2

[0020] Add 21.1 (0.106mol) grams of pyrophosphoric acid and 100.0 grams of chlorobenzene in the reaction flask, and heat it to 80°C. When the temperature in the reaction flask reaches 80°C, add 10.0 grams (0.0265mol) of the compound in batches 1. After reacting at 93°C for 2 hours, cool down to 80°C; add 10.0 g (0.106 mol) of hydrochloric acid solution, keep stirring at 80°C for 1.0 hour, drop to room temperature and separate layers, take the lower layer containing the product and put it in a clean reaction bottle During the process, ethanol was added dropwise to the reaction bottle, and after crystallization, it became oily solid phostiamine, which could not be filtered.

Embodiment 3

[0022] Add 21.1 grams (0.106mol) of pyrophosphoric acid with a mass ratio of 90% and 100.0 grams of toluene to the reaction flask, and heat it to 80°C. When the temperature in the reaction flask reaches 80°C, add 10.0 grams (0.0265mol) of compound 1 in batches , after reacting at 95°C for 2 hours, cool down to 80°C; add 10.0 g (0.106 mol) of hydrochloric acid solution, keep stirring at 80°C for 1.0 hour, drop to room temperature and separate layers, take the lower layer containing the product and put it in a clean reaction bottle , add acetone dropwise to the reaction flask, filter after crystallization, rinse the filtered solid with 5 mL of acetone, and dry to obtain 11.4 g of phostiamine, moisture: 1.8%, purity: 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com