Vermicular graphite cast iron material and preparation method and application thereof

A technology for vermicular graphite cast iron and crushed iron, which is applied in the field of vermicular graphite cast iron materials and its preparation, can solve the problems of poor comprehensive performance of vermicular rate, hinder promotion and application, and low utilization rate of alloys, so as to improve the vermicularization effect and facilitate the Creeping treatment, excellent effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

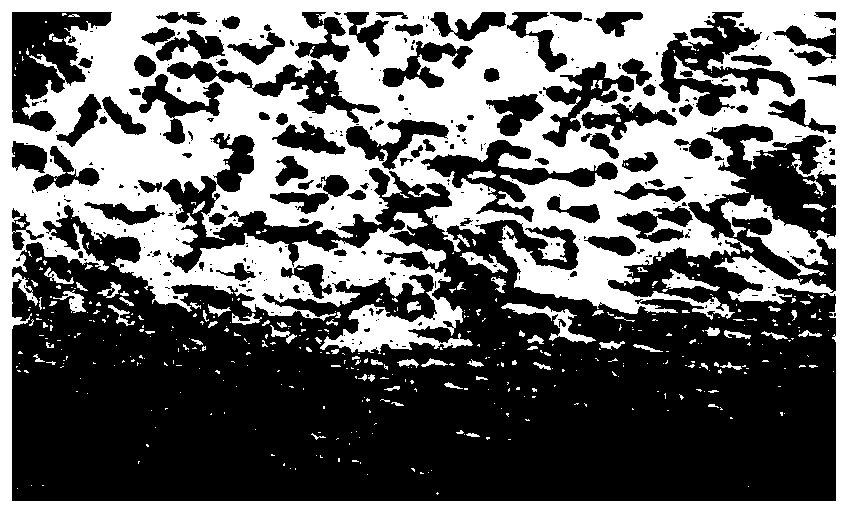

Image

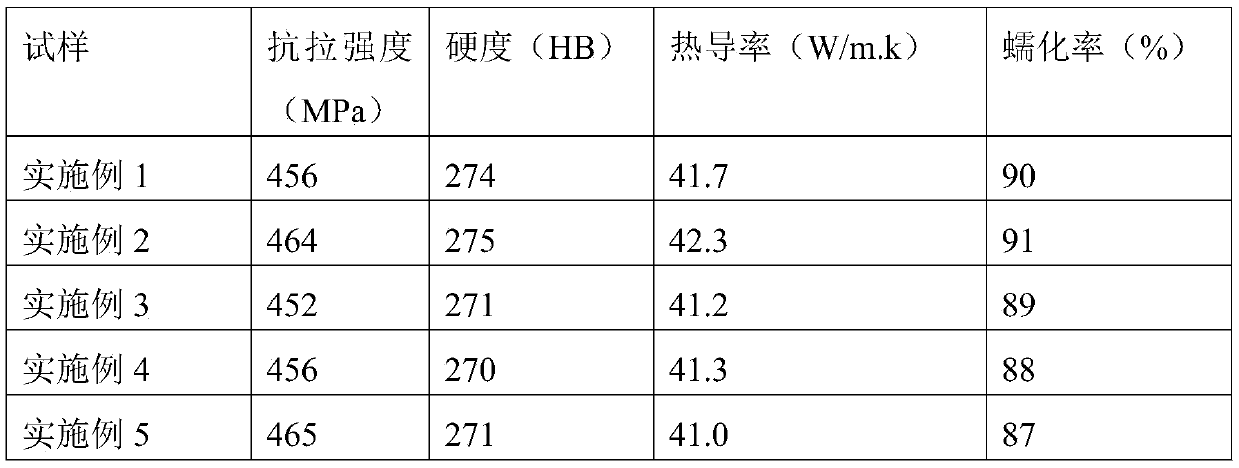

Examples

Embodiment 1

[0030] A vermicular graphite cast iron material, including the following main components by mass percentage: 3.65% carbon, 2.34% silicon, 0.006% copper, 0.02% sulfur, 0.02% phosphorus, 0.24% manganese, and 0.056% chromium %, the balance is iron and unavoidable impurities.

[0031] A preparation method of vermicular graphite cast iron material, comprising the following steps:

[0032] Step 1: Weigh steel scrap, recarburizer, ferrosilicon and ferromanganese, add materials into the molten pool, start smelting, and obtain smelting liquid, and control the temperature of the molten pool at 1440-1450°C;

[0033] The order of feeding is 5% steel scrap, 0.75% recarburizer, 5% scrap steel, 1% ferrosilicon, 5% steel scrap, 1.25% recarburizer, 5% scrap steel, 0.83% recarburizer and the remaining scrap steel,

[0034] Step 2: Sampling and analyzing the smelting liquid in step 1, adding ferrosilicon and ferromanganese to adjust the smelting liquid to pass;

[0035] Step 3: vermicularize t...

Embodiment 2

[0046] A vermicular graphite cast iron material, including the following main components by mass percentage: 3.57% carbon, 1.93% silicon, 0.027% copper, 0.015% sulfur, 0.04% phosphorus, 0.48% manganese, and 0.06% chromium %, the balance is iron and unavoidable impurities.

[0047] A preparation method of vermicular graphite cast iron material, comprising the following steps:

[0048] Step 1: Weigh steel scrap, recarburizer, ferrosilicon and ferromanganese, add materials into the molten pool, start melting, and obtain a melting liquid, and control the temperature of the molten pool at 1380°C;

[0049] The feeding sequence is 5% steel scrap, 0.83% recarburizer, 8.3% scrap steel, 1.5% ferrosilicon, 1.25% recarburizer, 5% scrap steel, 1.25% recarburizer and the remaining scrap steel;

[0050] Step 2: Sampling and analyzing the smelting liquid in step 1, adding ferrosilicon, ferromanganese and copper to adjust the smelting liquid to pass;

[0051] Step 3: vermicularize the smelting...

Embodiment 3

[0062] A vermicular graphite cast iron material, including the following main components by mass percentage: 3.18% carbon, 2.37% silicon, 0.026% copper, 0.01% chromium, 0.02% sulfur, 0.01% phosphorus, and 0.24% manganese %, the balance is iron and unavoidable impurities.

[0063] A preparation method of vermicular graphite cast iron material, comprising the following steps:

[0064] Step 1: Weigh steel scrap, recarburizer, ferrosilicon and ferromanganese, add materials into the molten pool, start smelting, and obtain smelting liquid, and control the temperature of the molten pool at 1427°C;

[0065] The feeding sequence is 16.7% steel scrap, 0.83% recarburizer, 16.7% scrap steel, 0.83% recarburizer, 16.7% scrap steel, 0.83% recarburizer, 16.7% scrap steel, 2% ferrosilicon and the remaining scrap steel;

[0066] Step 2: Sampling and analyzing the smelting liquid in step 1, adding ferromanganese and steel scrap to adjust the smelting liquid to pass;

[0067] Step 3: vermicular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com