A kind of high safety lithium-ion battery negative electrode composite material and preparation method thereof

A lithium-ion battery and composite material technology, which is applied in the field of high-safety lithium-ion battery negative electrode composite materials and their preparation, can solve the problems of heat dissipation performance deviation, safety performance deviation, inability to realize the self-closing function of materials, etc., and achieves improved safety performance. , the effect of preventing thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

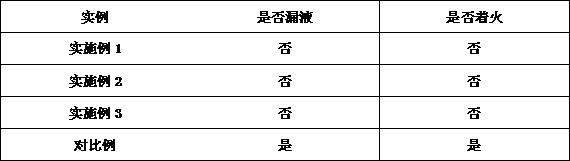

Examples

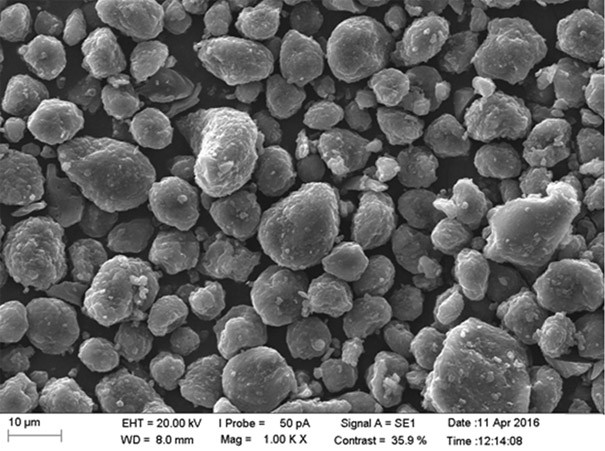

Embodiment 1

[0017] A high-safety lithium-ion battery negative electrode composite material includes an inner core and a cladding layer covering the inner core, the inner core is graphite, the cladding layer is a thermally denatured composite material, and the thickness of the cladding layer is 0.5-1 μm. The thickness of the coating layer is too thin. When the heat-denatured material melts or swells, the pores between the particles cannot be effectively reduced or disappeared, and the thermal shutdown effect cannot be realized, and the thermal runaway of the battery cannot be prevented, which is detrimental to the safety performance of the lithium-ion battery; If the coating layer is too thick, when the thermally denatured material melts or swells, the pores between the particles can disappear quickly, which can realize the thermal shutdown effect and effectively prevent the thermal runaway of the battery. There is no reaction to lithium ions, too thick a coating layer will directly affect ...

Embodiment 2

[0023] Based on the structures and components of the above-mentioned embodiments, this embodiment discloses a specific example.

[0024] A. Preparation of thermally denatured composite material coating solution: Add 45g of polyvinyl alcohol to 100g of N-methylpyrrolidone organic solvent, stir evenly, then add 55g of ethylene-vinyl acetate copolymer to dissolve evenly, and then add 3g Aminated graphene, 0.7g ammonium benzenesulfonate, and 0.3g ethylene glycol monobutyl ether were uniformly dispersed by ultrasonic to obtain a uniform coating solution.

[0025] B. Weigh 150g of artificial graphite with a particle size of 8 µm, add it to the coating solution A and disperse it evenly through a ball mill, dry, pulverize, and classify to obtain a graphite composite material with a small particle size, and then mix the composite material B Transfer to a tube furnace, first pass argon gas to exhaust the gas in the tube, and then pass SO 2 Gas, the flow rate is 2ml / min, and the tempera...

Embodiment 3

[0027] Based on the structure and components of Embodiment 1, this embodiment discloses a specific example.

[0028] A. Preparation of thermally denatured composite material coating solution: Add 40g of polyvinyl alcohol to 100g of N-methylpyrrolidone organic solvent, stir evenly, then add 60g of ethylene-vinyl acetate copolymer to dissolve evenly, and then add 1g Aminated graphene, 0.3 g of ammonium benzenesulfonate, and 0.2 g of ethylene glycol monobutyl ether were uniformly dispersed by ultrasonic to obtain a uniform coating solution.

[0029] B. Weigh 100g of artificial graphite with a particle size of 5 µm, add it to the coating solution A and disperse it evenly through a ball mill, dry, pulverize, and classify to obtain a graphite composite material with a small particle size, and then mix the composite material B Transfer to a tube furnace, first pass argon gas to exhaust the gas in the tube, and then pass SO 2 Gas, the flow rate is 10ml / min, and the temperature is rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com