Double-triple plasma waste gas treatment process

A plasma and exhaust gas treatment technology, applied in the direction of gas treatment, separation method, dispersed particle separation, etc., can solve the problems of low safety, low treatment rate of harmful molecules, no long-term effect, etc., achieve good purification effect, Effect of long-term use and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

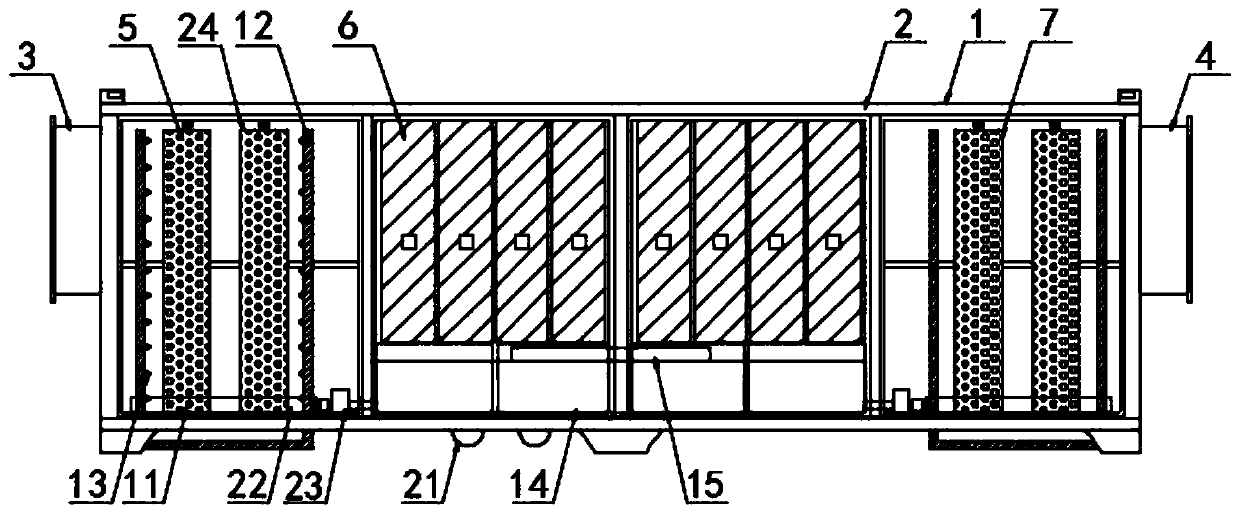

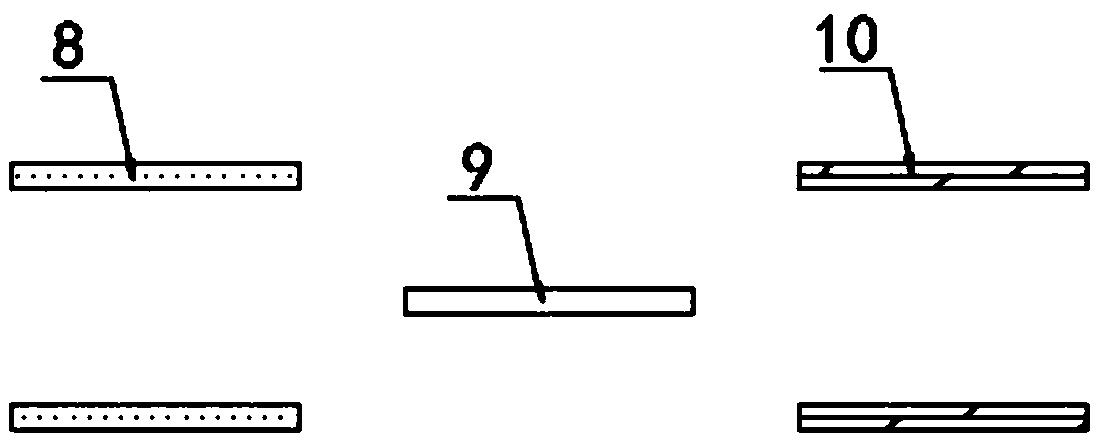

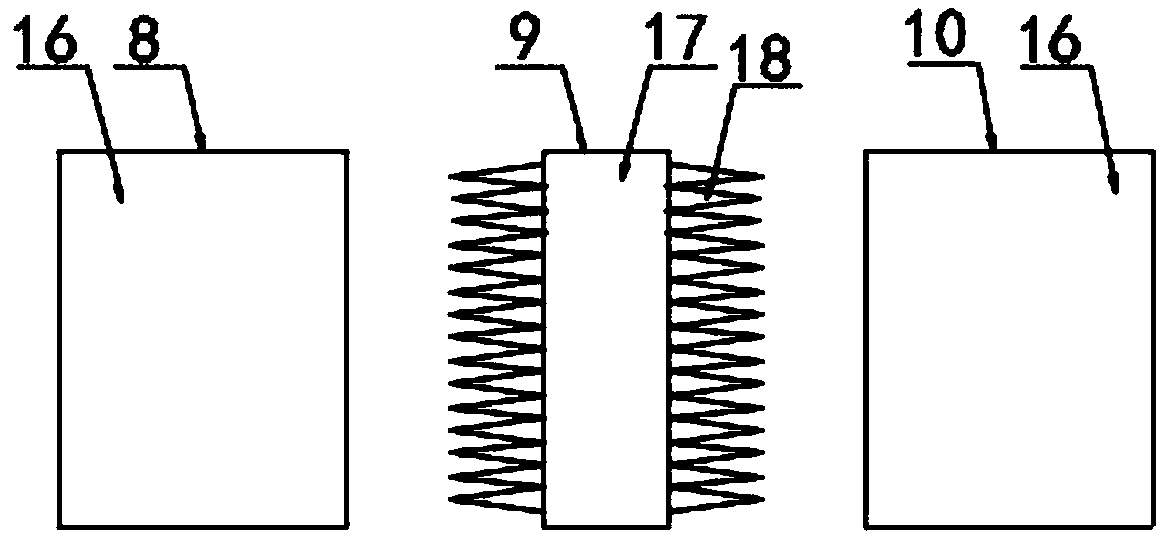

[0033] according to figure 1A double-three plasma exhaust gas treatment process shown includes an exhaust gas treatment device 1, the exhaust gas treatment device 1 includes a box body 2, and the box body 2 is provided with an air inlet 3 on one side and an air outlet on the other side 4. The inside of the box 2 is provided with a pre-processing module 5, a plasma module 6 and a post-processing module 7 arranged in sequence from left to right, and the plasma module 6 includes a first module 8 arranged in sequence from left to right , an intermediate module 9 and a second module 10, the pretreatment module 5 and the posttreatment module 7 all include a frame 24 and a volcanic rock filler 11, the frame 24 is made of SUS304 material, and the volcanic rock filler 11 is arranged on the inside of the frame 24 , the volcanic rock filler 11 is provided with honeycomb holes, and the dust removal effect is good. Both sides and the top of the pretreatment module 5 and the posttreatment m...

Embodiment 2

[0038] The present invention also provides a double-three plasma waste gas treatment process, the specific steps of the waste gas treatment process are as follows:

[0039] Step 1: Exhaust gas pretreatment, the exhaust gas is drawn into the interior of the box body 2 through the air inlet 3 by the induced draft fan, and the exhaust gas is initially filtered through the volcanic rock filler 11 on the pretreatment module 5, which can effectively absorb dust particles in the exhaust gas, thereby further To ensure the long-term efficient and stable operation of the plasma module 6 on the rear side, the waste gas can also be sucked in from the air outlet 4 for waste gas treatment and then discharged from the air inlet 3;

[0040] Step 2: double-three plasma exhaust gas treatment, powering the plasma module 6 through the adaptive power supply 15, forming a fan-shaped plasma field by the second line structure electrode 17 and a plurality of needle-point electrodes 18 on both sides, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com