Fertilizer suitable for tea and preparation method thereof

A fertilizer and tea technology, which is applied in the field of tea special fertilizer and its preparation, can solve the problems of organic fertilizer exceeding the environmental carrying capacity, low utilization rate of organic fertilizer, and soil structure damage, so as to improve water and fertilizer retention capacity, facilitate crop absorption, The effect of solving soil problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

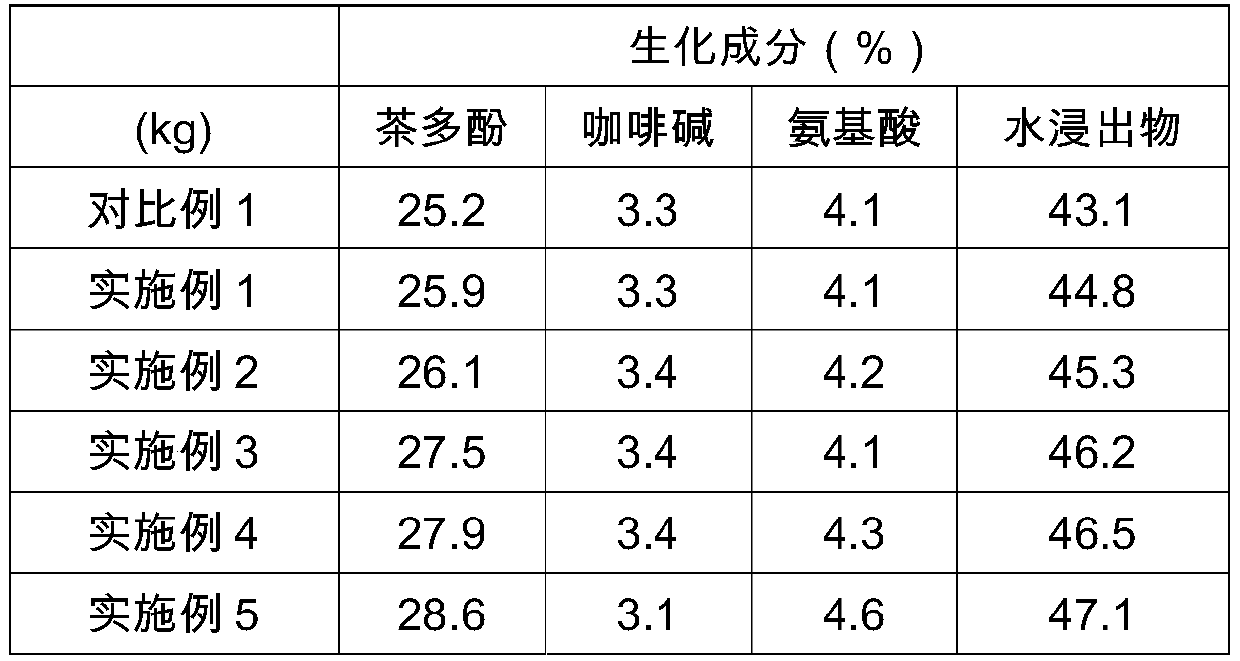

Examples

Embodiment 1

[0030] Raw materials: 200 parts of livestock manure, 250 parts of tea tree by-products, 10 parts of Bacillus subtilis and 50 parts of modified starch.

[0031] Preparation method: carry out anaerobic fermentation on livestock feces for 5-8 days; crush tea tree by-products; add the crushed tea tree by-products to livestock feces and add deionized water to make the water content of the mixture reach 65% -75%; add microbial agent, carry out secondary fermentation, fermentation time is 40-60 days, collect solid matter by suction filtration; add the obtained solid matter into modified starch, mix and stir evenly, and dry quickly at 50-80°C , to obtain fertilizers with a particle diameter of 2 mm to 8 mm.

[0032] The preparation method of the modified starch is as follows: get 1000 kg of corn starch and put it into a kneader, dissolve 1 kg of sodium tripolyphosphate, 1 kg of urea and 0.5 kg of hydrochloric acid with 8 liters of water, stir until completely dissolved, then spray the...

Embodiment 2

[0034] Raw materials: 300 parts of livestock manure, 200 parts of tea tree by-products, 20 parts of Bacillus subtilis and 120 parts of modified starch. Wherein the preparation method of modified starch is identical with embodiment 1.

[0035] Preparation method: carry out anaerobic fermentation on livestock feces for 5-8 days; crush tea tree by-products; add the crushed tea tree by-products to livestock feces and add deionized water to make the water content of the mixture reach 65% -75%; add microbial agent, carry out secondary fermentation, fermentation time is 40-60 days, collect solid matter by suction filtration; add the obtained solid matter into modified starch, mix and stir evenly, and dry quickly at 50-80°C , to obtain fertilizers with a particle diameter of 2 mm to 8 mm.

Embodiment 3

[0037] Raw materials: 500 parts of livestock manure, 250 parts of tea tree by-products, 150 parts of mushroom dregs, 10 parts of Bacillus subtilis and 50 parts of modified starch. Wherein the preparation method of modified starch is identical with embodiment 1.

[0038] Preparation method: carry out anaerobic fermentation on livestock feces for 5-8 days; grind tea tree by-products and mushroom dregs separately; add the pulverized tea tree by-products and mushroom dregs to livestock manure and add deionized water , so that the water content of the mixture reaches 65%-75%; add microbial agents for secondary fermentation, the fermentation time is 40-60 days, and collect the solid matter by suction filtration; add the obtained solid matter into modified starch, and mix and stir evenly Quickly dry at 50-80°C to obtain a fertilizer with a particle diameter of 2mm-8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com