Polystyrene-based carbonized microsphere, preparation method and application thereof

A polystyrene-based, carbonized microsphere technology, applied in chemical instruments and methods, dyed low-molecular-weight organic compound treatment, dyed high-molecular-weight organic compound treatment, etc., can solve the problem that calcium carbonate cannot meet the processing requirements of polymer materials , to achieve the effect of improving interfacial compatibility, improving compatibility, improving mechanical and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

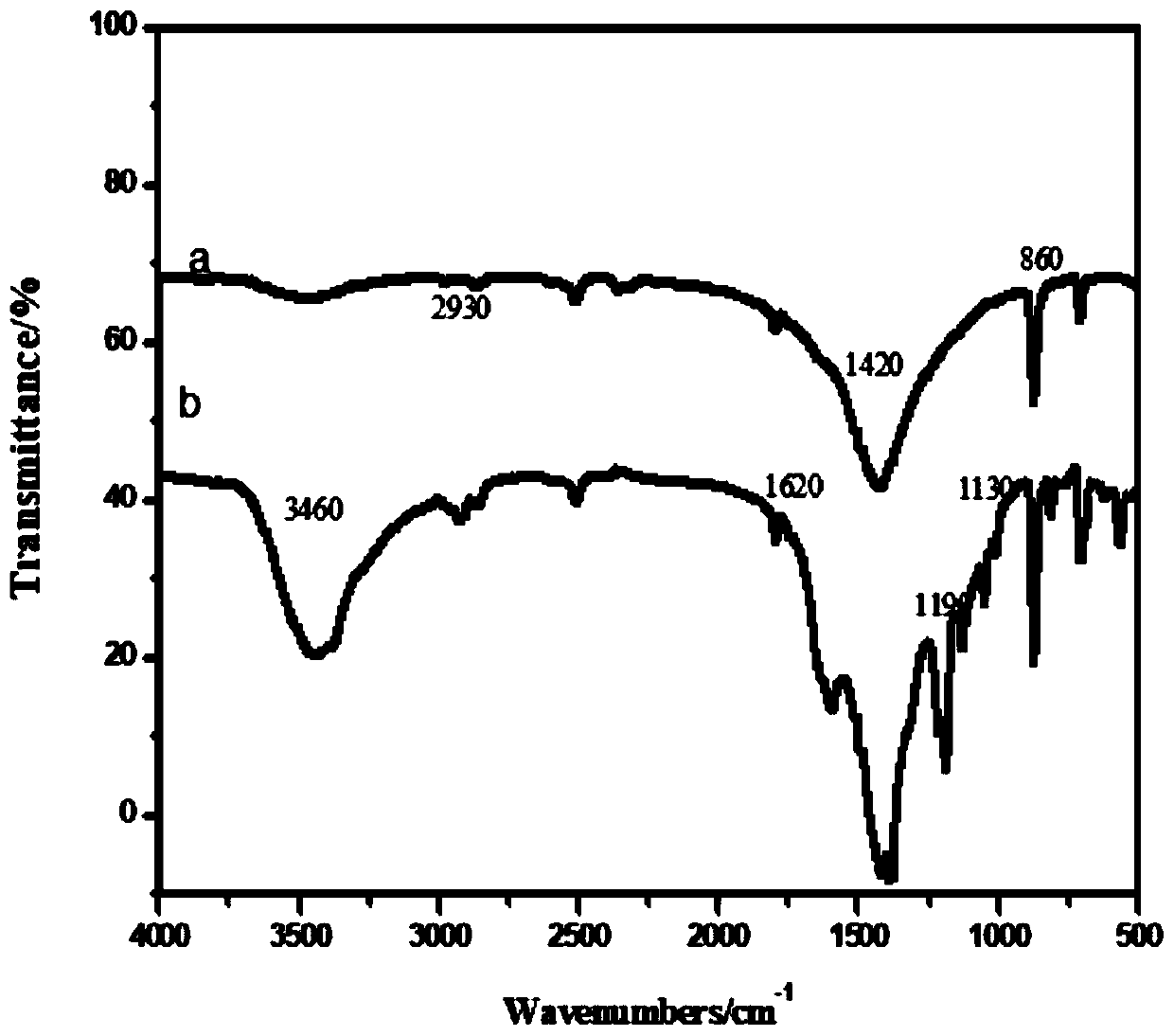

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing polystyrene-based carbonized microspheres, comprising the following steps:

[0043] S10, using a modifier to modify calcium carbonate to obtain modifier-coated calcium carbonate; wherein, the modifier contains a sulfonic acid group and a vinyl group;

[0044] S20, performing a cross-linking polymerization reaction on the calcium carbonate coated with the modifier and styrene under the action of a cross-linking agent and an initiator to obtain polystyrene-coated calcium carbonate;

[0045] S30, carbonizing the polystyrene-based coated calcium carbonate to obtain polystyrene-based carbonized microspheres.

[0046] Above-mentioned calcium carbonate can select light calcium carbonate and heavy calcium carbonate, is preferably light calcium carbonate. Further, calcium carbonate can be directly dispersed in a solvent to prepare a calcium carbonate dispersion to participate in the reaction. Preferably, before the calcium carbonate ...

Embodiment 1

[0093] (1) Weigh 100g light calcium carbonate and 100g dehydrated ethanol in the reaction bottle and fully mix them, put them into an agate jar and ball mill them on a ball mill for 6 hours at a speed of 400rpm, then dry and sieve for subsequent use;

[0094] (2) Transfer 100g of light calcium carbonate after ball milling to a reaction flask with mechanical stirring, then add 100g of water and disperse at a speed of 480rpm for 30min at 60°C;

[0095] (3) After adjusting the stirring speed to 200rpm, slowly add 7g p-vinylbenzenesulfonic acid, react for 2h, (there will be carbon dioxide bubbles to emerge during the reaction), and obtain calcium carbonate coated with modifier;

[0096] (4) keep the temperature at 60°C, slowly add 0.21g styrene, 0.14g divinylbenzene, 0.14g dibenzoyl peroxide (dibenzoyl peroxide is first dissolved in ethanol) in the reaction flask, Carry out cross-linking reaction, obtain polystyrene-based coated calcium carbonate after reaction 2h;

[0097] (5) S...

Embodiment 2

[0125] Present embodiment 2 is basically the same as embodiment 1, and difference is: the program of temperature control is as follows:

[0126] Raise the temperature at a rate of 10°C / min to 250°C, then raise the temperature at a rate of 2°C / min to 280°C for 4 hours, then raise the temperature at a rate of 10°C / min to 400°C, and then increase the temperature at a rate of 5°C / min to 500°C, then raised to 600°C at a rate of 2°C / min for 4 hours, and then cooled to room temperature at a rate of 2°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com