Method for culturing saccharomyces cerevisiae Y3401 to produce ethanol and application of saccharomyces cerevisiae Y3401 in white spirit brewing

A technology of Saccharomyces cerevisiae and medium, which is applied in the field of microorganisms, and can solve problems such as difficulty in realizing mechanized control, difficulty in developing solid-state brewing technology, and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

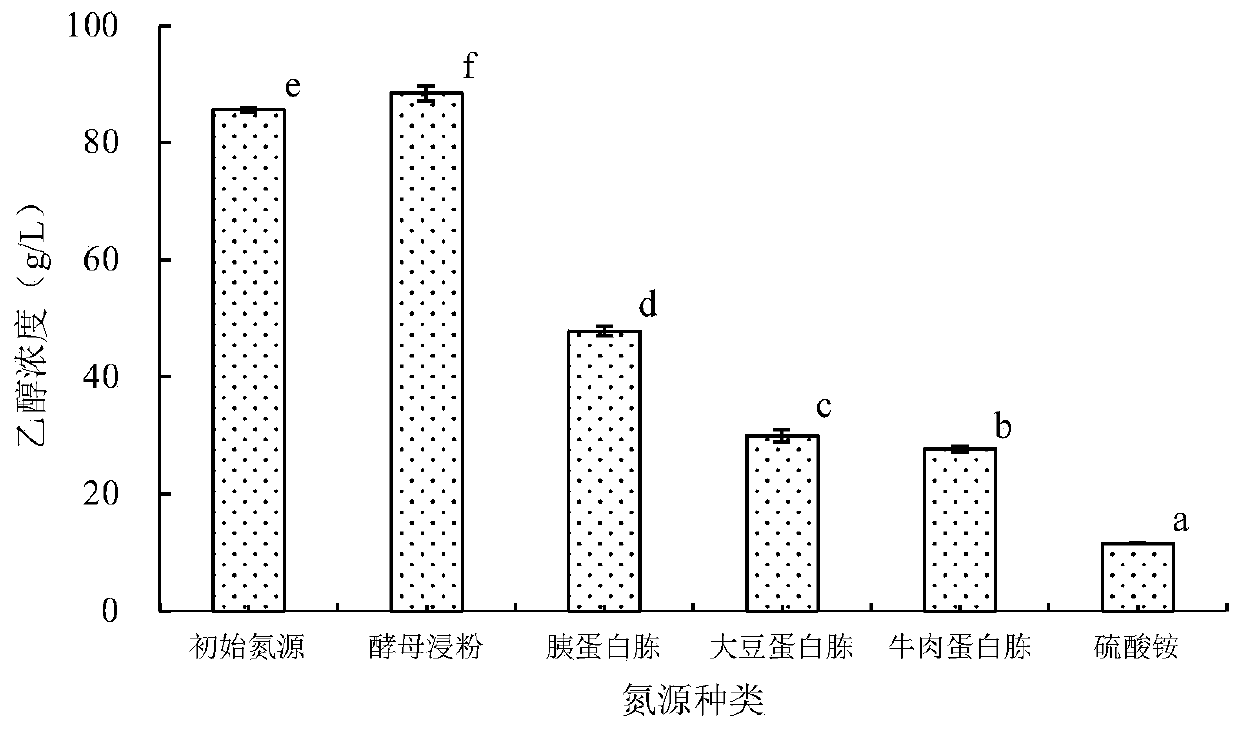

[0040] Embodiment one: the single factor test of culture condition of Saccharomyces cerevisiae (Saccharomyces cerevisiae) Y3401

[0041] In order to study the fermentation of yeast Y3401 to produce more ethanol, this example conducted an optimization experiment on the culture conditions of the strain.

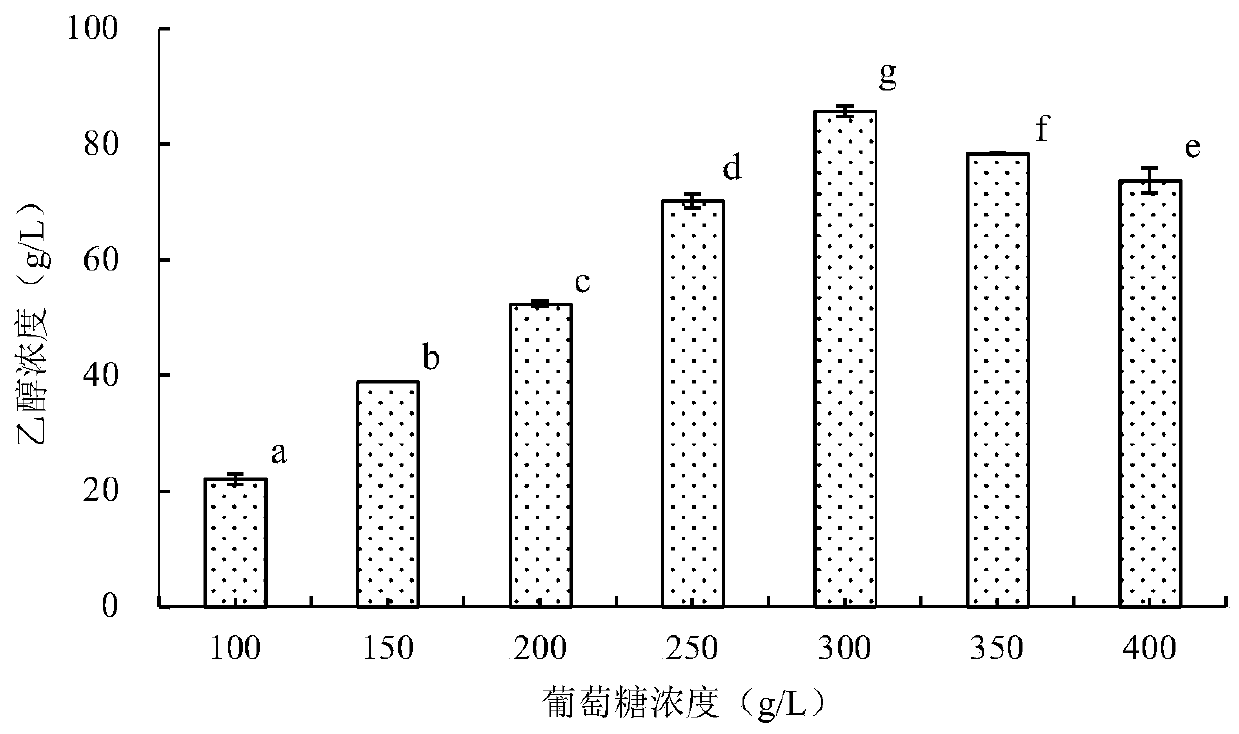

[0042] 1. Initial concentration of glucose

[0043] Saccharomyces cerevisiae Y3401 was inoculated in YPD and cultured for 24 hours. Take 100 μL of seed solution and inoculate in ethanol fermentation medium with different initial glucose concentrations (100, 150, 200, 250, 300, 350 and 400 g / L), culture at 30 °C, 120 r / min for 24 h, and measure ethanol production concentration.

[0044] Depend on figure 1 It can be seen that the concentration of ethanol produced by yeast Y3401 increases first and then decreases with the increase of the initial concentration of glucose. When the initial concentration of glucose is 300g / L, the concentration of ethanol reaches the maximum value, ...

Embodiment 2

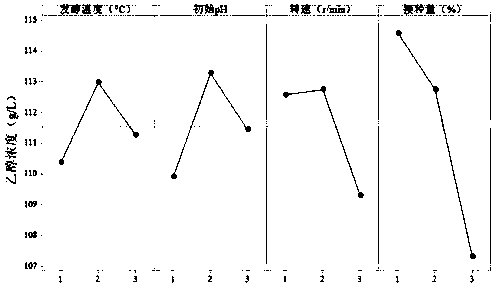

[0071] Embodiment two: Orthogonal experiment of Saccharomyces cerevisiae (Saccharomyces cerevisiae) Y3401 culture conditions

[0072] According to the results of the single factor test, after significant analysis of the data, four factors of fermentation temperature, initial pH, rotational speed and inoculum volume were selected for L 9 (3 4 ) Orthogonal experiment to determine the optimal process conditions for yeast Y3401 fermentation to produce ethanol. Orthogonal test factor levels are shown in Table 1.

[0073] Table 1 Orthogonal test factor level table

[0074]

[0075] The experimental results show that from the range R analysis D>C=B>A in Table 2, it can be seen that the inoculum size has the greatest impact on the ethanol production effect of yeast Y3401, followed by the rotation speed and initial pH, and the temperature has the least impact on the fermentation effect. From the analysis of the K value results, it can be seen that the optimal process combination ...

Embodiment 3

[0079] Embodiment three: Saccharomyces cerevisiae (Saccharomyces cerevisiae) Y3401 shaking and static culture experiments

[0080] Because the yeast Y3401 ethanol-producing fermentation process was tested in Example 1, on this basis, the inventor combined the optimum conditions (except the rotating speed) obtained by the orthogonal experiment of Example 2 to carry out the previous shaking culture (8 , 16, 24, 32), the mixed culture method of static culture in the later stage was used to explore better culture conditions and obtain the effect of higher ethanol production.

[0081] Because the analysis in the above-mentioned implementation 1 shows that in the early stage of cultivation, it is mainly a preparatory stage for ethanol production-that is, the yeast biomass accumulation process, while the middle and late stages are the ethanol production stage in a relatively anaerobic environment. For this reason, we consider shaking in the early stage to provide Sufficient oxygen ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com