Antibacterial non-heat-sealed tea filter paper and production technology thereof

A non-heat-sealing, tea filter paper technology, applied in filter paper, paper, papermaking and other directions, can solve the problems of no antibacterial property, high price, and high production cost of tea filter paper, achieve significant market prospects and practical significance, improve strength, improve Effects of wet and dry strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0048] 1) after thawing the bleached softwood pulp, prepare slurry A with a concentration of 4.0%;

[0049] 2) Part of the slurry A is beaten with a double-disc mill beater, and the pulp after beating is 40°SR, and the slurry B with a wet weight of 14g;

[0050] 3) slurry A and slurry B are mixed to obtain mixed slurry C, by dry weight, slurry A is 60 parts, slurry A is 40 parts, and the concentration of mixed slurry C is 2.0%. Add PAE wet strength agent to the slurry C, the dosage is 4.0% of the dry weight of the mixed slurry C;

[0051] 4) adding carboxymethyl cellulose into water, stirring and dissolving to prepare a coating solution with a concentration of 0.5%;

[0052] 5) The mixed slurry is formed by an inclined wire paper machine, the concentration on the net is 0.005%, and the formed paper is dried and rolled by a dryer to obtain a non-heat-sealable tea filter paper, and the temperature of the dryer is 140°C.

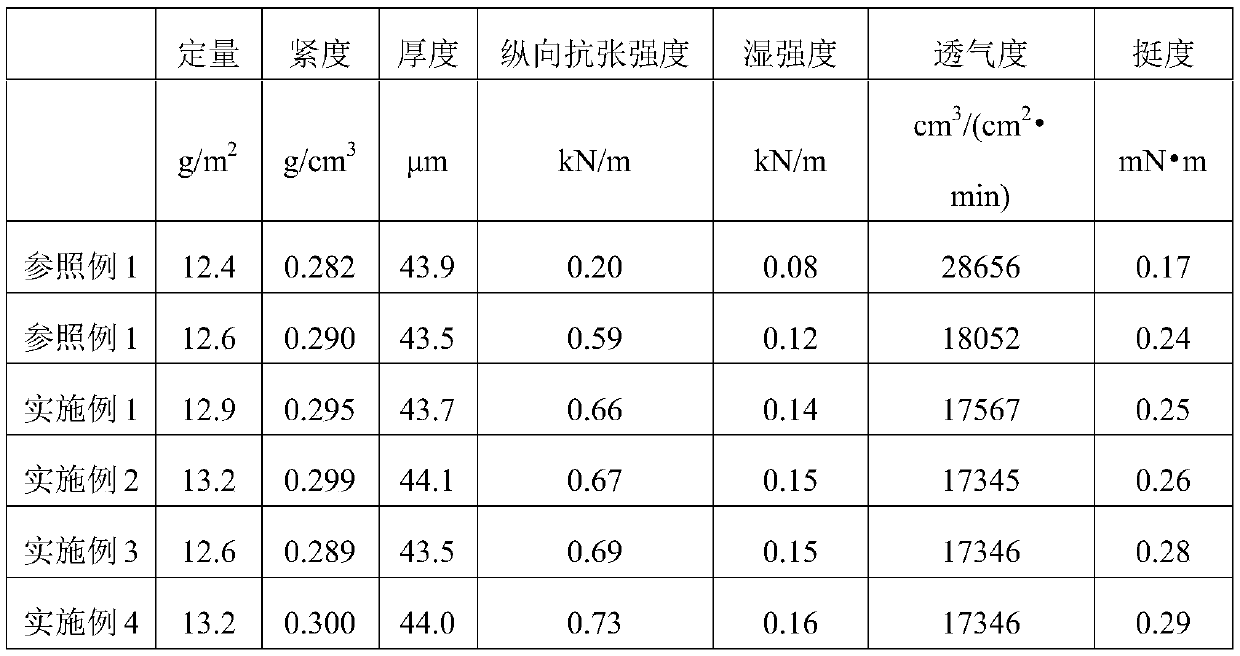

Embodiment 1

[0054] 1) after thawing the bleached softwood pulp, prepare slurry A with a concentration of 4.0%;

[0055] 2) Part of the slurry A is beaten with a double-disc mill beater, and the pulp after beating is 40°SR, and the slurry B with a wet weight of 14g;

[0056] 3) Mix slurry A and slurry B to obtain mixed slurry C, by dry weight, slurry A is 60 parts, slurry B is 40 parts, and the concentration of mixed slurry C is 2.0%. Add PAE wet strength agent to the slurry C, the dosage is 4.0% of the dry weight of the mixed slurry C;

[0057] 4) Add carboxymethyl cellulose and chitosan to water, stir and dissolve to prepare a coating solution with a concentration of 0.5%, by dry weight, the weight ratio of carboxymethyl cellulose and chitosan is 8: 1;

[0058] 5) The mixed slurry is formed by an inclined wire paper machine, the concentration on the net is 0.005%, and the formed paper is dried by a drying cylinder, and the dipping coating is adopted, and the coating amount is 0.6g / m 2...

Embodiment 2

[0060] 1) after thawing the bleached softwood pulp, prepare slurry A with a concentration of 4.0%;

[0061] 2) Part of the slurry A is beaten with a double-disc mill beater, and the pulp after beating is 40°SR, and the slurry B with a wet weight of 14g;

[0062] 3) slurry A and slurry B are mixed to obtain mixed slurry C, by dry weight, slurry A is 65 parts, slurry B is 35 parts, and the concentration of mixed slurry C is 2.0%. Add PAE wet strength agent to the slurry C, the dosage is 4.0% of the dry weight of the mixed slurry C;

[0063] 4) Add carboxymethyl cellulose and chitosan to water, stir and dissolve and prepare a coating solution with a concentration of 0.8%. On a dry weight basis, the weight ratio of carboxymethyl cellulose and chitosan is 6: 1;

[0064] 5) The mixed slurry is formed by an inclined wire paper machine, the concentration on the net is 0.005%, and the formed paper is dried by a drying cylinder, and the dipping coating is adopted, and the coating amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com