Method for improving antibacterial property of polyurethane coating by utilizing hydrophilic chain extender

A hydrophilic chain extender and polyurethane coating technology, which is applied in polyurea/polyurethane coatings, antifouling/underwater coatings, biocide-containing paints, etc., can solve the problem of not being directly soluble in water and difficult to disperse in water and other problems, to achieve high strength, good toughness, and obvious antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

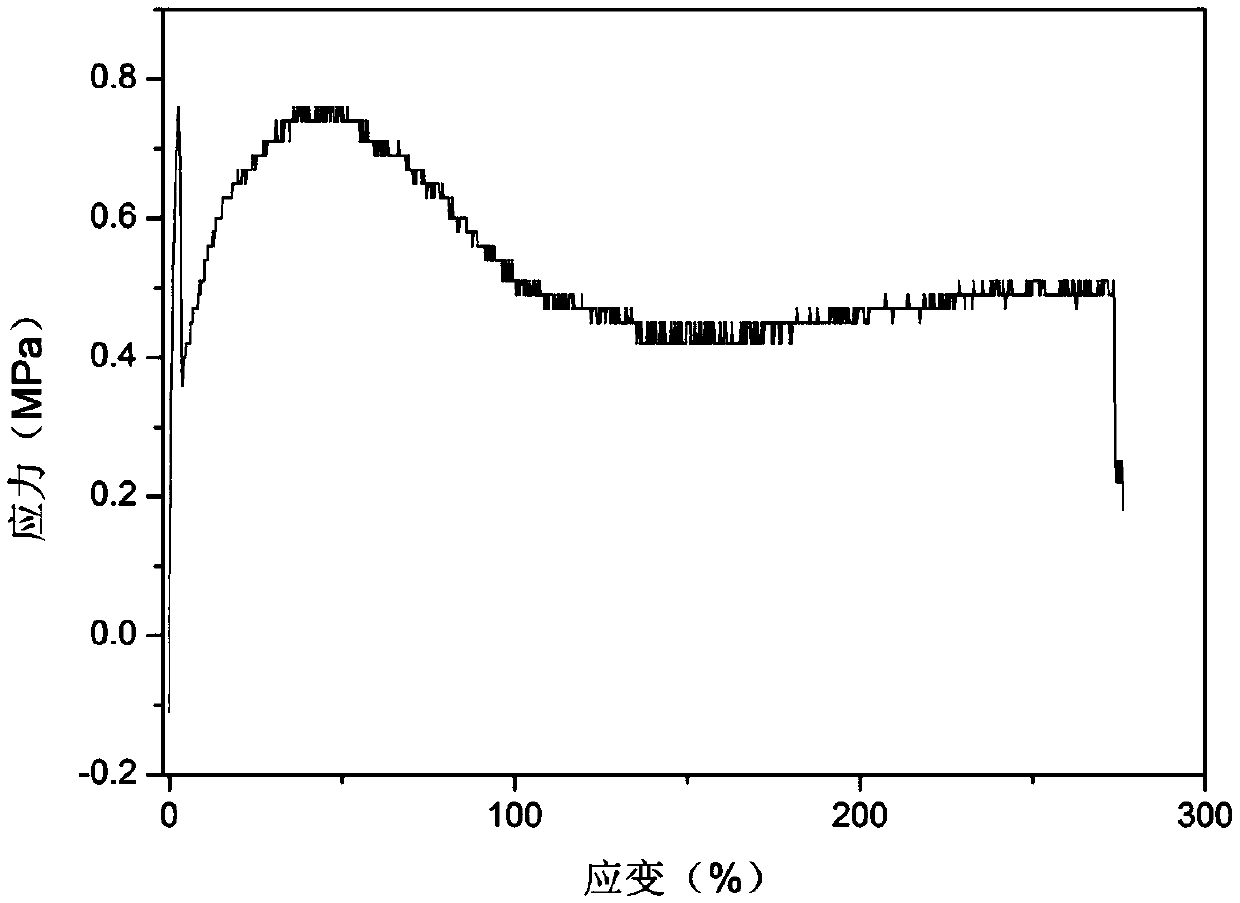

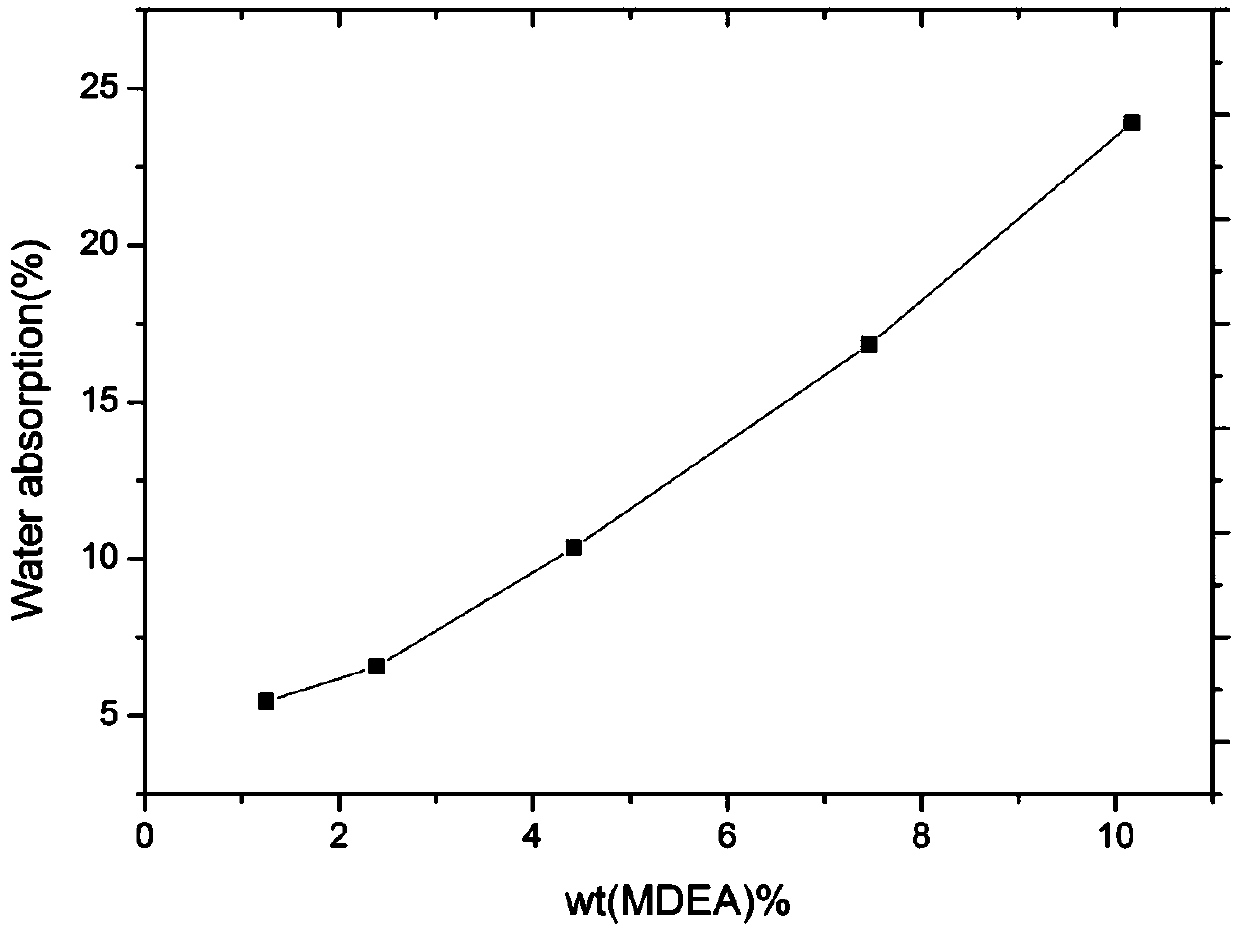

[0033] In a four-necked flask equipped with a thermometer and a condenser tube, add 0.005mol of polytetrahydrofuran diol, dehydrate under vacuum at 90°C for half an hour, cool down to 70°C, add 0.026mol of isophorone diisocyanate, 0.1ml of dilauric acid Dibutyltin, reacted for 3 hours. Cool down to below 50°C, add 10g of acetone to dilute the prepolymer, add 0.015mol N-methyldiethanolamine, raise the temperature to 70°C and react for 5 hours. Lower the temperature to below 50°C and add 5 g of acetone, and add 0.015 mol of glacial acetic acid at room temperature to react for half an hour. Add 35 g of deionized water containing antimicrobial agent dropwise into a constant pressure dropping funnel, and emulsify at a high stirring rate. After stirring for 10 minutes, the acetone was removed by rotary evaporation to obtain a stable emulsion with a hydrophilic group content of 10% by weight of the polymer. The emulsion was coated on a polytetrafluoroethylene board, and dried at 60...

example 2

[0035] In a four-necked flask equipped with a thermometer and a condenser tube, add 0.005mol of polytetrahydrofuran diol, dehydrate under vacuum at 90°C for half an hour, cool down to 70°C, add 0.0195mol of isophorone diisocyanate, 0.1ml of dilauric acid Dibutyltin, reacted for 3 hours. Cool down to below 50°C, add 10g of acetone to dilute the prepolymer, add 0.01mol N-methyldiethanolamine, raise the temperature to 70°C and react for 5 hours. Lower the temperature to below 50°C and add 5 g of acetone, and add 0.01 mol of glacial acetic acid at room temperature to react for half an hour. Add 35 g of the aqueous solution containing the antibacterial agent dropwise into the constant-pressure dropping funnel, and emulsify at a high stirring speed. After stirring for 10 minutes, the acetone was removed by rotary evaporation to obtain a stable emulsion with a hydrophilic group content of 7.5% by weight of the polymer. The emulsion was coated on a polytetrafluoroethylene board, and...

example 3

[0037] In a four-necked flask equipped with a thermometer and a condenser tube, add 0.005mol of polytetrahydrofuran diol, dehydrate under vacuum at 90°C for half an hour, cool down to 70°C, add 0.013mol of isophorone diisocyanate, 0.1ml of dilauric acid Dibutyltin, reacted for 3 hours. Cool down to below 50°C, add 10g of acetone to dilute the prepolymer, add 0.005mol N-methyldiethanolamine, raise the temperature to 70°C and react for 5 hours. Lower the temperature to below 50°C and add 5 g of acetone, and add 0.005 mol of glacial acetic acid at room temperature to react for half an hour. Add 35 g of the aqueous solution containing the antibacterial agent dropwise into the constant-pressure dropping funnel, and emulsify at a high stirring rate. After stirring for 10 minutes, the acetone was removed by rotary evaporation to obtain a stable emulsion with a hydrophilic group content of 4.5% by mass fraction of the polymer. The emulsion was coated on a polytetrafluoroethylene boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com