Resin composition, resin film, and liquid crystal display element

A resin composition and resin film technology, applied in the directions of liquid crystal materials, instruments, chemical instruments and methods, can solve problems such as the reduction of light utilization efficiency, and achieve the effects of inhibiting peeling and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

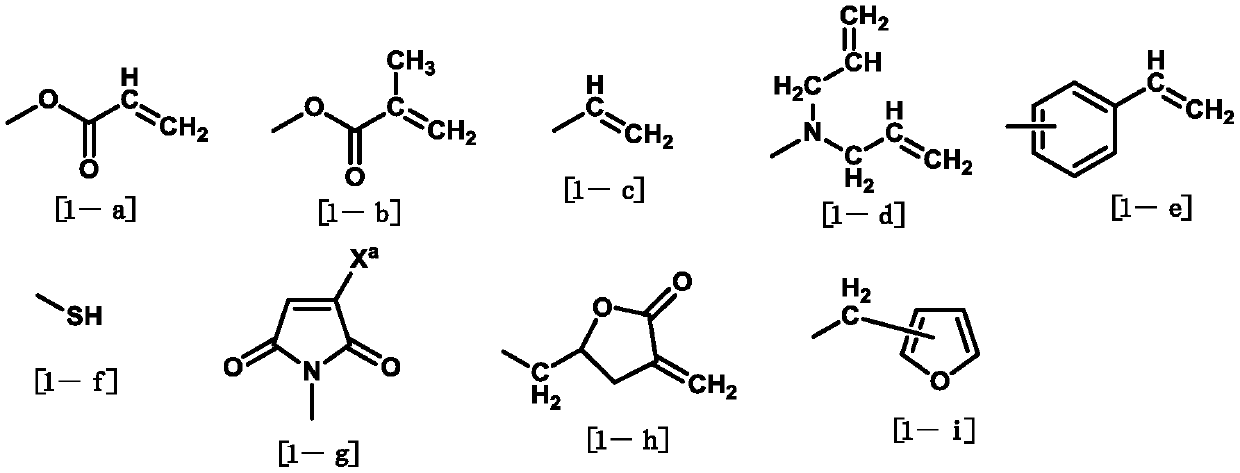

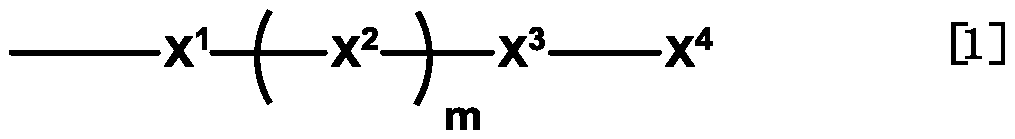

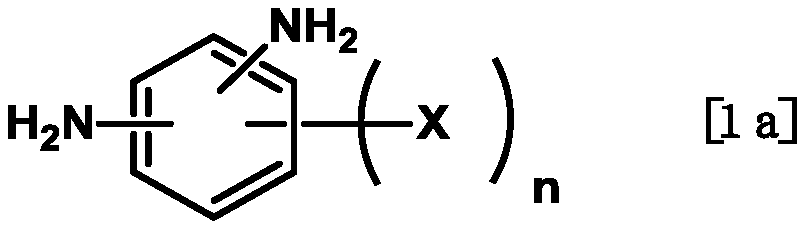

[0156] Examples are listed below to illustrate the present invention in more detail, but are not limited to them. The abbreviations used in the following are as follows.

[0157]

[0158] L1: MLC-2003 (manufactured by Merck Ltd.)

[0159]

[0160]

[0161] R3: Blemmer TA-604AU (manufactured by NOF Corporation)

[0162]

[0163]

[0164]

[0165]

[0166]

[0167]

[0168]

[0169]

[0170]

[0171]

[0172]

[0173] E1: 3-methacryloxypropyl trimethoxysilane

[0174] E2: Tetraethoxysilane

[0175]

[0176]

[0177]

[0178]

[0179]

[0180] NMP: N-methyl-2-pyrrolidone, γ-BL: γ-butyrolactone

[0181] BCS: ethylene glycol monobutyl ether

[0182] PB: Propylene glycol monobutyl ether

[0183] PGME: Propylene glycol monomethyl ether

[0184] ECS: ethylene glycol monoethyl ether

[0185] EC: Diethylene glycol monoethyl ether

[0186] [Molecular weight measurement of polyimide polymer]

[0187] Using a normal temperature gel permeation chromatography (GPC) device (GPC-101) (manufactured by Showa De...

Synthetic example 1

[0199] D2 (3.06g, 12.2 mmol), A1 (4.10g, 15.5 mmol) and C1 (1.68g, 15.5 mmol) were mixed in NMP (33.2g) and reacted at 80°C for 4 hours, then D1 was added (3.60 g, 18.4 mmol) and NMP (16.6 g) were reacted at 40°C for 6 hours to obtain a polyamic acid solution (1) having a resin solid content concentration of 20% by mass. The number average molecular weight (also referred to as Mn) of this polyamic acid was 18,500, and the weight average molecular weight (also referred to as Mw) was 66,500.

Synthetic example 2

[0201] After adding NMP to the polyamic acid solution (1) (30.0 g) obtained by the method of Synthesis Example 1 and diluting to 6 mass%, acetic anhydride (3.60 g) and pyridine (2.30 g) as imidization catalysts were added, React at 60°C for 1.5 hours. This reaction solution was poured into methanol (450 ml), and the obtained precipitate was obtained by filtration. This deposit was washed with methanol, and dried under reduced pressure at 100°C to obtain polyimide powder (2). The imidation ratio of this polyimide was 51%, Mn was 16,100, and Mw was 43,500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com