Degradation-resisting, good-compatibility and absorbable medical suture line and preparation method thereof

A suture and compatibility technology, applied in medical science, coating, surgery, etc., can solve the problems of non-decomposability, non-physiological, inconvenient use, etc., to maintain appearance and mechanical physical properties, good biological Compatibility, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

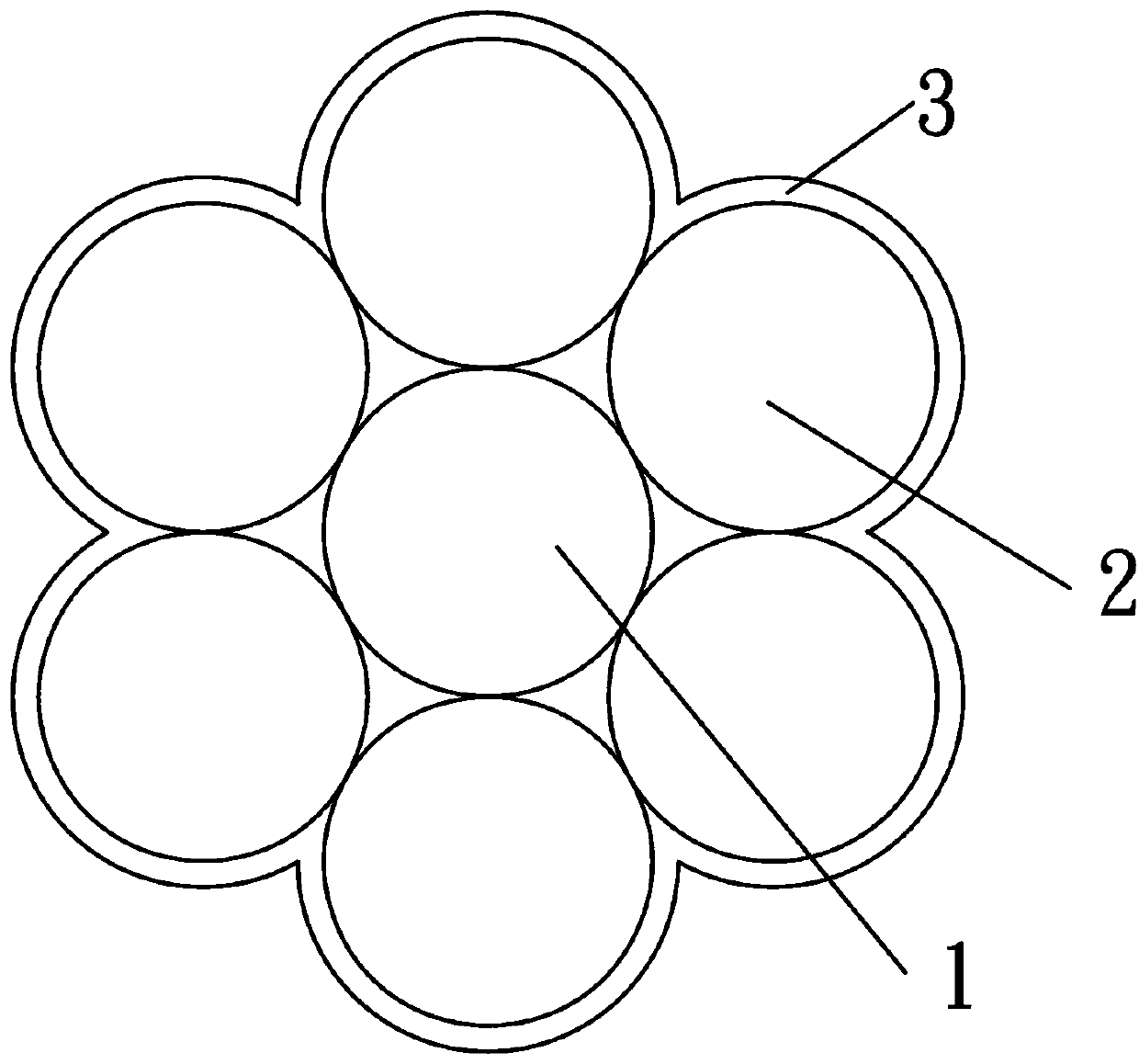

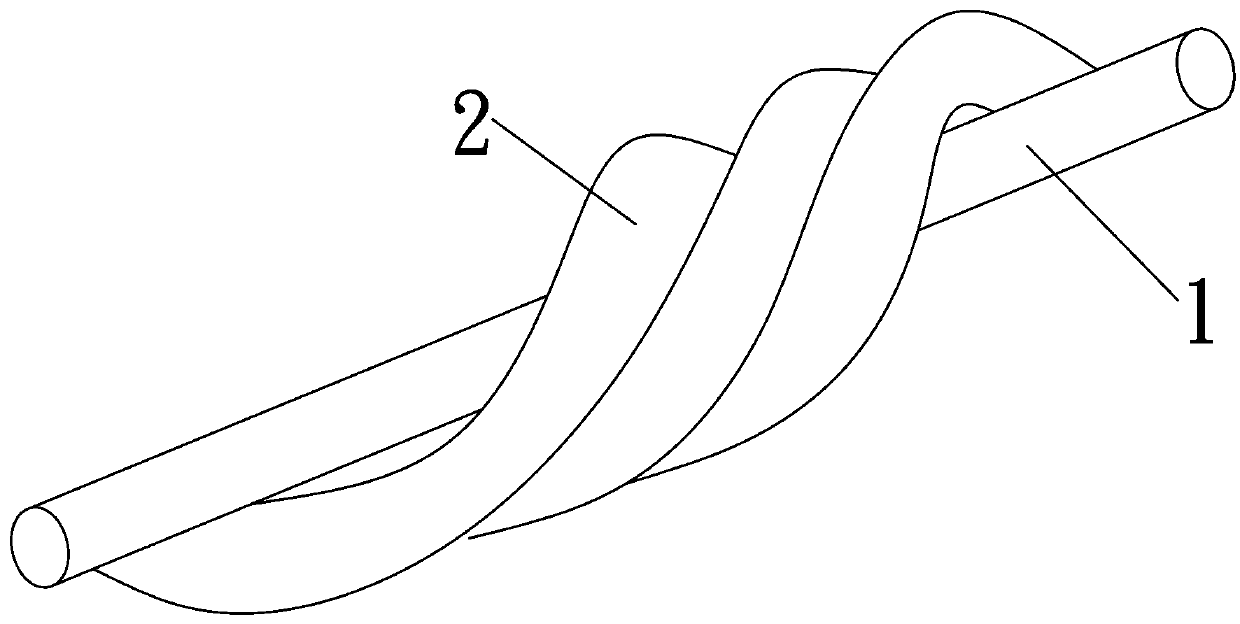

[0042] Such as Figure 1-4 As shown, a kind of absorbable medical suture with good degradation resistance and compatibility is characterized in that: the suture wire material is a multi-strand braided thread, including a core yarn 1, a braided layer 2 and an antibacterial coating layer 3, the described The braided layer 2 is arranged on the outer side of the core yarn 1, and the antibacterial coating layer 3 is arranged on the outer side of the braided layer 2. The core yarn 1 includes a suture one, and the raw materials of the suture one include by weight: polyglycolide 50- 70 parts, 15-35 parts of carbon fiber, 5-15 parts of pure natural collagen; the braided layer 2 includes suture two, and the raw materials of the second suture include: 50-70 parts of polyglycolide, carbon fiber 15-35 parts, 5-15 parts of pure natural collagen, 2-4 parts of mannitol, 3-5 parts of vanillin.

Embodiment 2

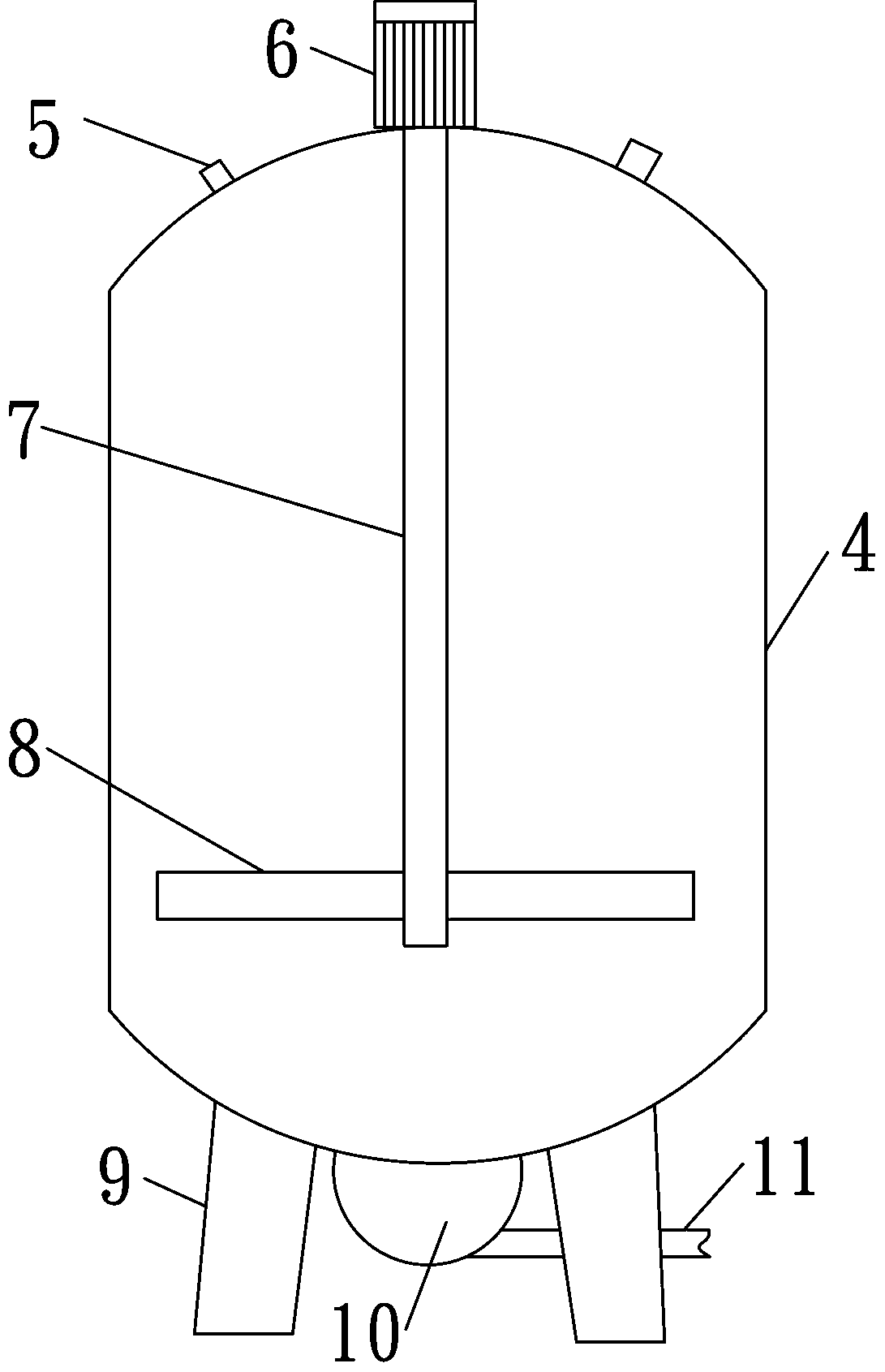

[0044] A method for preparing absorbable medical sutures with good degradation resistance and compatibility, comprising the steps of:

[0045] S1: Production of core yarn 1: S11, weigh raw materials, chitosan and hyaluronic acid as required, dissolve chitosan in acetic acid solution and stir to obtain the first mixture; S12, add hyaluronic acid into the first mixture , stirring at a speed of 150-200rpm for 5-8min, defoaming to obtain a coating solution; S13, coating the suture with the coating solution and then drying to obtain a core yarn 1;

[0046]S2: Fabrication of braided layer 2: S21, weigh raw materials, chitosan and hyaluronic acid as required, dissolve chitosan in acetic acid solution and stir to obtain the first mixture; S22, add hyaluronic acid into the first mixture , after stirring at a speed of 150-200rpm for 5-8min, defoaming to obtain a coating solution; S23, drying the suture thread 2 after coating it with the coating solution, to obtain a single-strand rope o...

Embodiment 3

[0051] The raw materials of the suture one include by weight: 65 parts of polyglycolide, 26 parts of carbon fiber, and 14 parts of pure natural collagen;

[0052] The raw materials of suture thread 2 include, by weight, 60 parts of polyglycolide, 30 parts of carbon fiber, 14 parts of pure natural collagen, 3 parts of mannitol, and 4 parts of vanillin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com