A process for synergistically producing calcium aluminate powder using power station boilers

A power plant boiler and calcium aluminate powder technology, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/aluminum oxide/aluminum hydroxide, chemical industry, etc., can solve the problem of unstable temperature field of rotary kiln and long product production cycle , over-burning or under-burning of raw materials, etc., to achieve the effects of stable production process parameters, improved energy utilization efficiency, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 (using pulverized coal boiler)

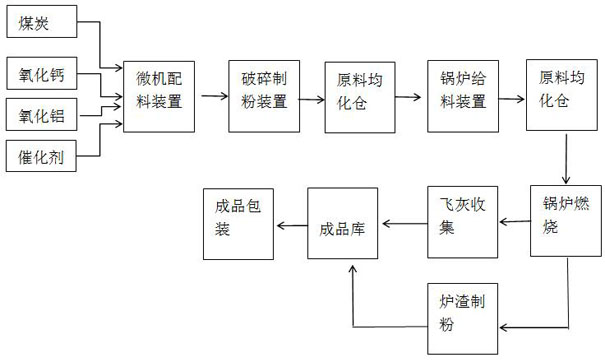

[0024] A process for producing calcium aluminate powder by utilizing a power station boiler, comprising the following steps:

[0025] (1) Using a microcomputer batching device to prepare raw materials, the raw materials include the following components by weight: 50% to 70% of coal, 10% to 20% of calcium oxide, 20% to 30% of alumina, and iron oxide (accounting for than 1%);

[0026] (2) After the raw materials are mixed, they are conveyed to the crusher (pulverizer) by the belt for crushing and pulverizing;

[0027] (3) The crushed powder materials are sent to the storage bin (homogenization bin) through the material conveyor;

[0028] (4) The material is controlled by the powder selection screen of the pulverizing device to control the particle size of the material to be 500~1000 mesh, and sent to the pulverized coal boiler through the boiler feeding device for combustion, and the temperature is controlled at 1200~1300 ℃;

...

Embodiment 2

[0031] Example 2 (using a fluidized bed boiler)

[0032] A process for producing calcium aluminate powder by utilizing a power station boiler, comprising the following steps:

[0033] (1) Using a microcomputer batching device to configure raw materials, the raw materials include the following components by weight: 50% to 70% of coal, 10% to 20% of calcium oxide, 20% to 30% of alumina, and gypsum (the proportion of 1%);

[0034] (2) After the raw materials are mixed, they are conveyed to the crusher (pulverizer) by the belt for crushing and pulverizing;

[0035] (3) The crushed powder materials are sent to the storage bin (homogenization bin) through the material conveyor;

[0036] (4) The material is controlled by the crusher screen to control the particle size of the material to be 0~13mm, and sent to the fluidized bed for combustion through the boiler feeding device, and the temperature is controlled at 850~1050℃;

[0037] (5) The fly ash after combustion is collected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com