Production process of granular ferrous chloride dihydrate

A ferrous chloride and production process technology, applied in the direction of ferric halide, etc., can solve the problems of easy agglomeration of products, high energy consumption, low production capacity of ferrous chloride dihydrate, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

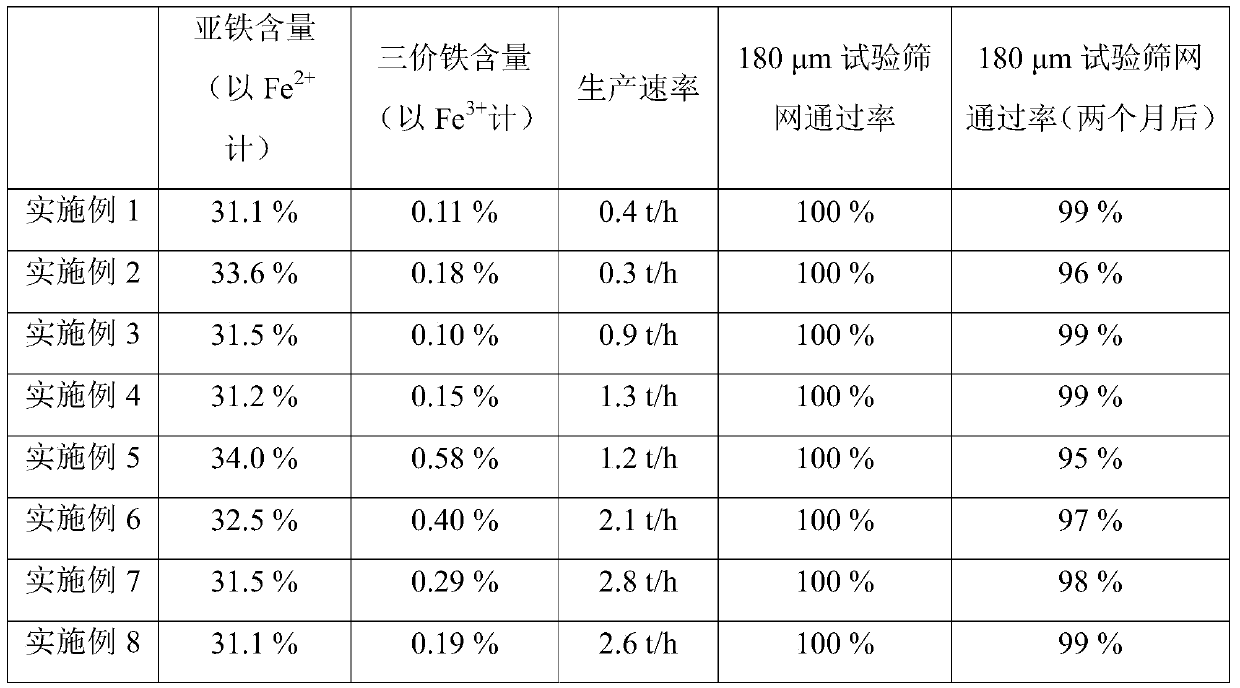

Examples

Embodiment 1

[0019] 1. The ferrous chloride solution obtained after pressure filtration is evaporated and concentrated, and the concentrated solution is continuously entered into a jacketed crystallization kettle with cooling water at a discharge rate of 2t / h for cooling;

[0020] 2. The concentrated solution of ferrous chloride is cooled in a crystallization kettle to obtain a concentrated solution in which ferrous chloride tetrahydrate crystals account for about 20%;

[0021] 3. The ferrous chloride concentrated solution obtained by cooling is continuously entered into the automatic centrifuge for centrifugation, and the solid falls from the outlet of the centrifuge to the conveyor belt of the conveyor to obtain ferrous chloride tetrahydrate crystals, and the mother liquor is returned to the raw material of ferrous chloride tank recycling;

[0022] 4. The output of the automatic centrifuge is discharged to the conveyor belt of the conveyor and continuously transported to the hopper of th...

Embodiment 2

[0027] 1. The ferrous chloride solution obtained after pressure filtration is evaporated and concentrated, and the concentrated solution is continuously entered into a jacketed crystallization kettle with cooling water at a discharge rate of 2t / h for cooling;

[0028] 2. The concentrated solution of ferrous chloride is cooled in a crystallization kettle to obtain a concentrated solution in which ferrous chloride tetrahydrate crystals account for about 20%;

[0029] 3. The ferrous chloride concentrated solution obtained by cooling is continuously entered into the automatic centrifuge for centrifugation, and the solid falls from the outlet of the centrifuge to the conveyor belt of the conveyor to obtain ferrous chloride tetrahydrate crystals, and the mother liquor is returned to the raw material of ferrous chloride tank recycling;

[0030] 4. The output of the automatic centrifuge is discharged to the conveyor belt of the conveyor and continuously transported to the hopper of th...

Embodiment 3

[0035] 1. The ferrous chloride solution obtained after pressure filtration is evaporated and concentrated, and the concentrated solution is continuously entered into a jacketed crystallization kettle with cooling water at a discharge rate of 5t / h for cooling;

[0036] 2. The concentrated solution of ferrous chloride is cooled in a crystallization kettle to obtain a concentrated solution in which ferrous chloride tetrahydrate crystals account for about 20%;

[0037] 3. The ferrous chloride concentrated solution obtained by cooling is continuously entered into the automatic centrifuge for centrifugation, and the solid falls from the outlet of the centrifuge to the conveyor belt of the conveyor to obtain ferrous chloride tetrahydrate crystals, and the mother liquor is returned to the raw material of ferrous chloride tank recycling;

[0038] 4. The output of the automatic centrifuge is discharged to the conveyor belt of the conveyor and continuously transported to the hopper of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com