Modified adhesive for bonding rubber and steel wire and production process thereof

A technology for adhesives and modifiers, applied in the field of adhesives, can solve the problems of unfavorable tensile properties of rubber compounds, accelerated aging of rubber hydrocarbons, and inability to obtain adhesion, etc., to achieve improved effects, stable performance, and guaranteed non-volatile Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

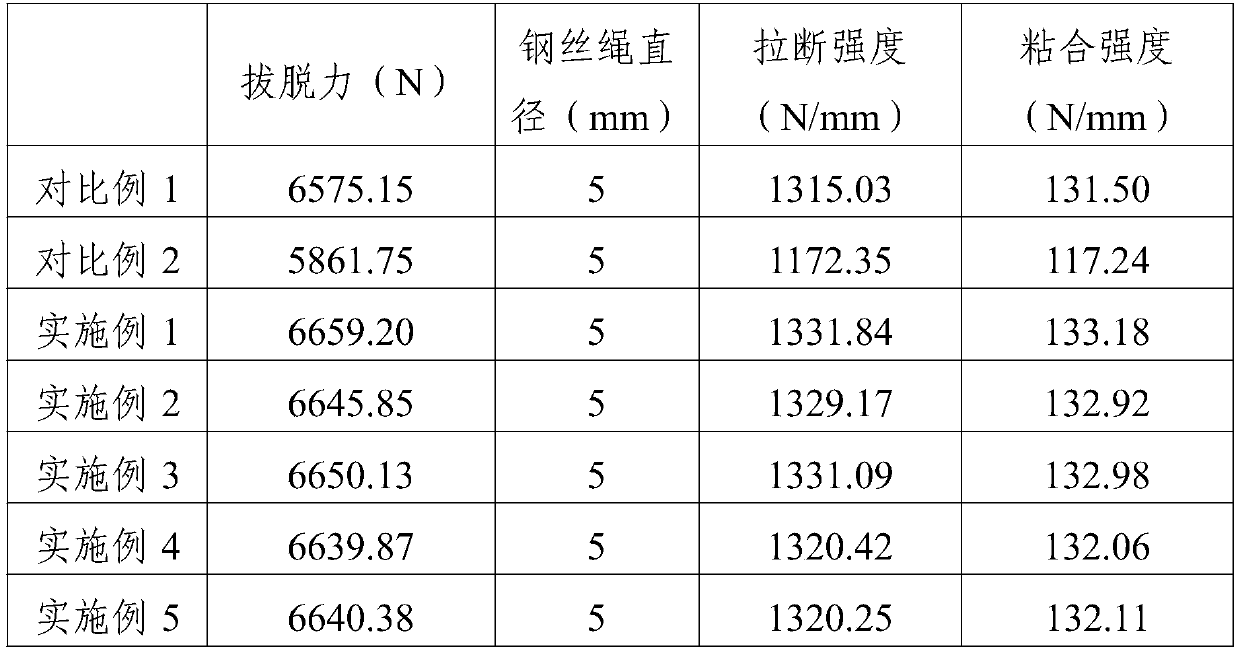

Examples

Embodiment 1

[0023] A modified adhesive used for bonding rubber and steel wire, the adhesive raw material includes the following components by weight: 25 parts of resorcinol, 40 parts of cobalt salt binder, 13 parts of white carbon black, 5 parts of stearic acid, 4 parts of silane coupling agent.

[0024] The production process of the adhesive for rubber and steel wire bonding comprises the following steps:

[0025] 1) Weigh resorcinol according to the proportion and put it into the reaction kettle, heat the reaction kettle to 70°C, start stirring for 10 minutes, the stirring speed is 150r / min, then add stearic acid according to the proportion, and stir for 25 minutes while adding;

[0026] 2) After adjusting the temperature of the resorcinol reaction kettle mixed with stearic acid to 30-40°C, start stirring at a stirring speed of 150r / min, weigh the cobalt salt binder and white carbon black in proportion and add them evenly After stirring for another 10 minutes, the material is discharge...

Embodiment 2

[0030] A modified adhesive for rubber and steel wire bonding, the adhesive raw material includes the following components by weight: 15 parts of resorcinol, 35 parts of cobalt salt binder, 10 parts of white carbon black, 5 parts of stearic acid, 3 parts of silane coupling agent.

[0031] The production process of the adhesive for rubber and steel wire bonding comprises the following steps:

[0032] 1) Weigh resorcinol according to the proportion and put it into the reaction kettle, heat the reaction kettle to 60°C, start stirring for 10 minutes, the stirring speed is 150r / min, then add stearic acid according to the proportion, and stir for 25 minutes while adding;

[0033] 2) Adjust the temperature of the resorcinol reaction kettle mixed with stearic acid to 40°C, start stirring at a stirring speed of 150r / min, weigh the cobalt salt binder and white carbon black in proportion and add them evenly After stirring for 10 minutes, the material is discharged to obtain a semi-finish...

Embodiment 3

[0037] A modified adhesive used for bonding rubber and steel wire, the adhesive raw material includes the following components by weight: 20 parts of resorcinol, 37 parts of cobalt salt binder, 14 parts of white carbon black, 4 parts of stearic acid, 3 parts of silane coupling agent.

[0038] The production process of the adhesive for rubber and steel wire bonding comprises the following steps:

[0039] 1) Weigh resorcinol according to the proportion and put it into the reactor, heat the reactor to 80°C, start stirring for 10 minutes, the stirring speed is 150r / min, then add stearic acid according to the proportion, and stir for 25 minutes while adding;

[0040] 2) Adjust the temperature of the resorcinol reaction kettle mixed with stearic acid to 30°C, start stirring at a stirring speed of 150r / min, weigh the cobalt salt binder and white carbon black in proportion and add them evenly After stirring for 10 minutes, the material is discharged to obtain a semi-finished product;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com