Method for rapidly evaluating dry-wet alternate marine environment corrosion of polyurethane elastomer coating

A polyurethane elastomer, marine environment technology, applied in weather resistance/light resistance/corrosion resistance, analytical materials, measuring devices, etc., can solve problems such as high cost, short test cycle, base metal corrosion, etc., to achieve accurate evaluation results, test The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

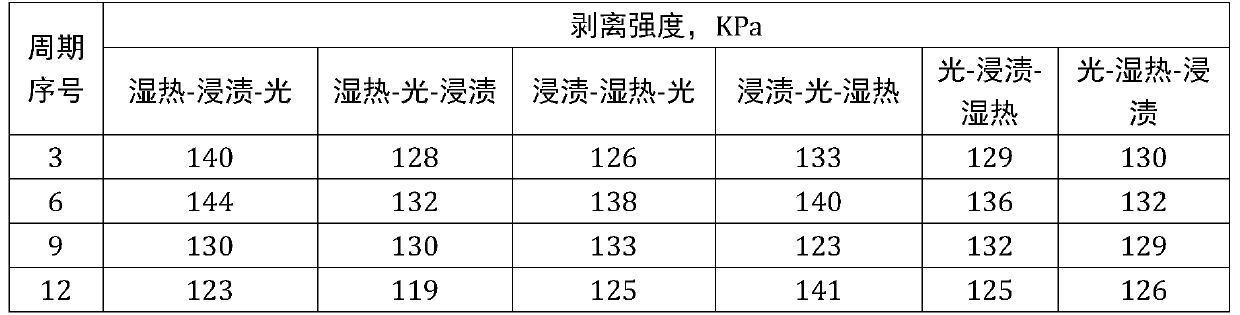

[0021] Taking Xiamen as an example, the test condition of the damp heat test module is 60°C / 85%RH; the test medium of the salt water immersion test module is 3.5wt% sodium chloride aqueous solution, and the test temperature is 60°C; 0.51W / m 2 (340nm).

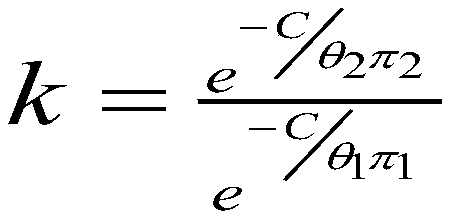

[0022] According to the meteorological data of Xiamen area in the past five years, the average annual temperature in Xiamen area is 18.7°C and the average annual humidity is 73%. According to the following formula, the equivalent conversion coefficient of the damp heat test is 0.084, and the corresponding laboratory damp heat aging time of one year in the natural environment is about 720h. In terms of the number of 12 test cycles, the damp heat time in each test cycle is 60h .

[0023]

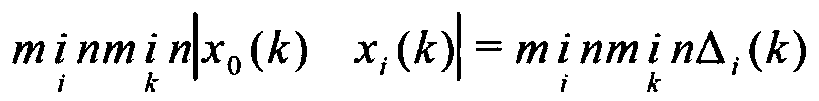

[0024] In the above formula: K is the time conversion coefficient; θ 2 π 2 is the actual exposed temperature and humidity, θ 1 π 1 is the temperature and humidity of the accelerated test, θ 1 When ≤60°C, C=46.1.

[0025] The annual s...

Embodiment 2

[0052] Taking Xiamen as an example, the test condition of the damp heat test module is 40°C / 80%RH; the test medium of the salt water immersion test module is 3.5wt% sodium chloride aqueous solution, and the test temperature is 50°C; the radiation intensity in the xenon arc light aging module 0.51W / m 2 (340nm).

[0053] According to the meteorological data of Xiamen area in the past five years, the average annual temperature in Xiamen area is 18.7°C and the average annual humidity is 73%. According to the method of embodiment one, calculate the equivalent conversion coefficient of damp heat test to be 0.132, then the laboratory damp heat aging time corresponding to one year in the natural environment is about 1160h, to carry out 8 test cycle numbers, then in each test cycle The humid heat time is 145h.

[0054] The annual solar radiation energy in Xiamen area is about 5000MJ / m 2 , the calculated laboratory light aging time for simulating one year's solar radiation is 1010h, ...

Embodiment 3

[0064] Taking Xiamen as an example, the test condition of the damp heat test module is 50°C / 75%RH; the test medium of the salt water immersion test module is 3.5wt% sodium chloride aqueous solution, and the test temperature is 40°C; the radiation intensity in the xenon arc light aging module 0.51W / m 2 (340nm).

[0065] According to the meteorological data of Xiamen area in the past five years, the average annual temperature in Xiamen area is 18.7°C and the average annual humidity is 73%. According to the method of embodiment one, calculate the equivalent conversion coefficient of damp heat test to be 0.117, the laboratory damp heat aging time corresponding to one year in the natural environment is about 1022h, to carry out 24 test cycle numbers, then in each test cycle Damp heat time is 43h.

[0066] The annual solar radiation energy in Xiamen area is about 5000MJ / m 2 , according to the following formula, the laboratory photoaging time for simulating one year's solar radiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com